Slip joint plumbing fixtures provide easy disassembly and adjustment by using a threaded collar and compression ring, making them ideal for repairs and replacements. Solvent weld fixtures create a permanent, airtight seal by chemically fusing plastic pipes and fittings, ensuring durability and leak resistance in long-term installations. Choosing between slip joint and solvent weld depends on the need for future maintenance versus a secure, lasting connection.

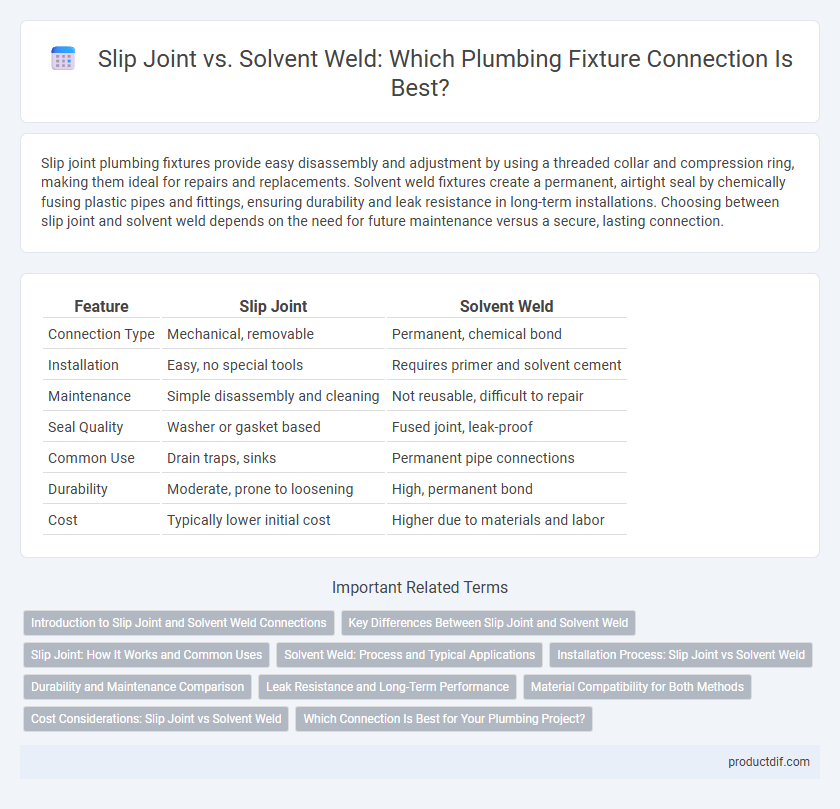

Table of Comparison

| Feature | Slip Joint | Solvent Weld |

|---|---|---|

| Connection Type | Mechanical, removable | Permanent, chemical bond |

| Installation | Easy, no special tools | Requires primer and solvent cement |

| Maintenance | Simple disassembly and cleaning | Not reusable, difficult to repair |

| Seal Quality | Washer or gasket based | Fused joint, leak-proof |

| Common Use | Drain traps, sinks | Permanent pipe connections |

| Durability | Moderate, prone to loosening | High, permanent bond |

| Cost | Typically lower initial cost | Higher due to materials and labor |

Introduction to Slip Joint and Solvent Weld Connections

Slip joint connections are flexible plumbing fixtures designed to join pipes using a threaded slip nut and compressible washer, allowing for easy disassembly and adjustments without permanent bonding. Solvent weld connections involve chemically fusing pipes and fittings using a solvent cement that softens and joins PVC or CPVC materials into a rigid, leak-proof seal, creating a permanent bond. Slip joints are ideal for applications requiring frequent maintenance or repositioning, while solvent welds provide durable, watertight connections for permanent installations.

Key Differences Between Slip Joint and Solvent Weld

Slip joint plumbing fixtures allow for easy disassembly and adjustments through a compression fitting mechanism, ideal for temporary or accessible connections. Solvent weld fixtures create permanent, watertight joints by chemically fusing PVC or other plastic pipes, offering superior durability and leak resistance. Slip joints are commonly used in traps and drain lines, whereas solvent welds are preferred for pressurized water systems and long-term installations.

Slip Joint: How It Works and Common Uses

Slip joint plumbing fixtures feature a threaded nut and a compression washer that create a watertight seal by tightening the joint, allowing for easy disassembly and reassembly without special tools. Commonly used in sink drains, traps, and other accessible plumbing connections, slip joints provide flexibility for maintenance and adjustments. This type of connection is ideal for situations requiring frequent access or repositioning, as it simplifies repairs compared to permanent solvent weld joints.

Solvent Weld: Process and Typical Applications

Solvent weld involves applying a chemical solvent to plastic pipe surfaces, softening the material to create a fused, watertight joint upon curing. This method is typically used with PVC and CPVC pipes in residential and commercial plumbing systems for waste, vent, and drainage applications. Its strong, permanent bond makes it ideal for underground installations, irrigation systems, and where high-pressure resistance is required.

Installation Process: Slip Joint vs Solvent Weld

Slip joint plumbing fixtures feature a threaded design allowing for easy hand-tightening and simple adjustments during installation without specialized tools. Solvent weld connections require applying a chemical solvent to soften PVC surfaces, which are then pressed together to create a permanent, watertight bond. Slip joints enable quick disassembly and maintenance, whereas solvent weld installations necessitate curing time and provide a more durable, leak-resistant seal.

Durability and Maintenance Comparison

Slip joint plumbing fixtures offer ease of maintenance with their adjustable, reusable connectors, making them suitable for temporary or less permanent applications. Solvent weld fixtures create a chemically fused joint, providing superior durability and leak resistance for long-term plumbing systems. While slip joints may require periodic tightening, solvent welds demand minimal maintenance but are more challenging to disassemble.

Leak Resistance and Long-Term Performance

Slip joint fittings offer moderate leak resistance due to their compression seals but may require periodic tightening to maintain a secure connection, potentially compromising long-term performance. Solvent weld fittings create a permanent, chemically bonded joint that provides superior leak resistance and enhanced durability over time, making them ideal for high-pressure and concealed plumbing. The choice between slip joint and solvent weld relies on balancing ease of installation with long-term reliability in plumbing systems.

Material Compatibility for Both Methods

Slip joint connections typically use rubber or plastic washers, making them highly compatible with various pipe materials such as PVC, ABS, copper, and metal, allowing for easy disassembly and reuse. Solvent weld fittings require chemically compatible thermoplastic materials like PVC or CPVC, as the solvent cement chemically bonds the pipe and fitting, creating a permanent, leak-proof seal that is not suitable for metals or rubber components. Choosing between slip joint and solvent weld methods depends largely on the type of pipe material and the need for flexibility versus a permanent connection.

Cost Considerations: Slip Joint vs Solvent Weld

Slip joint fittings typically offer lower upfront costs due to their reusable and adjustable nature, making them ideal for temporary or repair plumbing jobs. Solvent weld fittings involve a slightly higher initial expense but provide a more permanent, leak-proof seal that reduces long-term maintenance costs. Budget-conscious projects often favor slip joints for flexibility, while investments in durability prioritize solvent weld connections.

Which Connection Is Best for Your Plumbing Project?

Slip joint connections offer easy installation and reusable flexibility, making them ideal for temporary or repair plumbing projects, especially under sinks. Solvent weld connections create a permanent, leak-proof bond by chemically fusing PVC or CPVC pipes, ensuring durability and longevity in drain, waste, and vent systems. Choosing between slip joint and solvent weld depends on the need for accessibility versus a long-lasting, secure connection in your plumbing design.

Slip joint vs Solvent weld Infographic

productdif.com

productdif.com