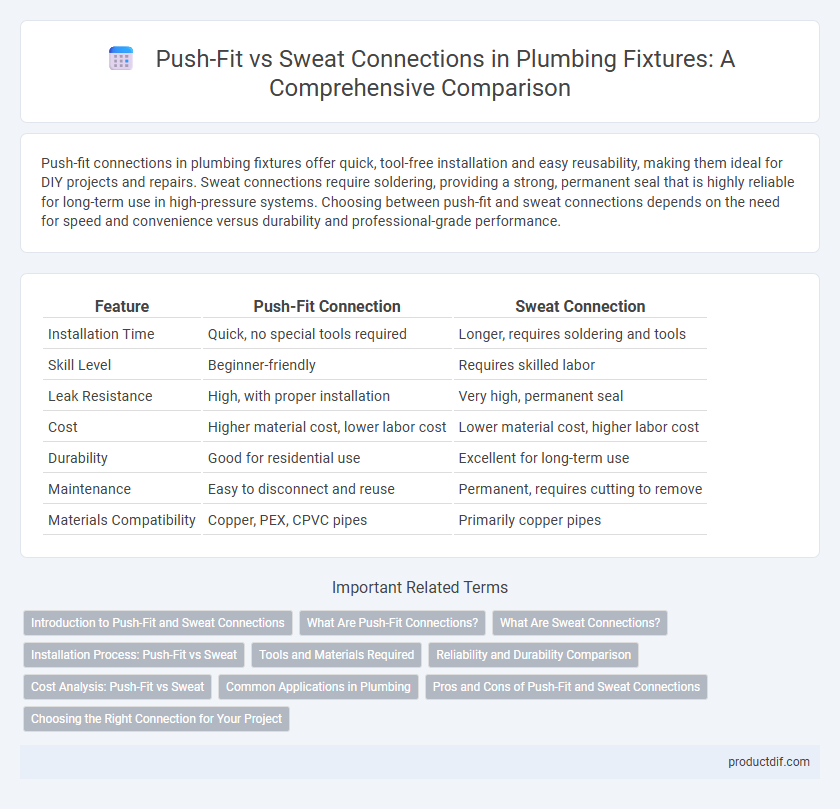

Push-fit connections in plumbing fixtures offer quick, tool-free installation and easy reusability, making them ideal for DIY projects and repairs. Sweat connections require soldering, providing a strong, permanent seal that is highly reliable for long-term use in high-pressure systems. Choosing between push-fit and sweat connections depends on the need for speed and convenience versus durability and professional-grade performance.

Table of Comparison

| Feature | Push-Fit Connection | Sweat Connection |

|---|---|---|

| Installation Time | Quick, no special tools required | Longer, requires soldering and tools |

| Skill Level | Beginner-friendly | Requires skilled labor |

| Leak Resistance | High, with proper installation | Very high, permanent seal |

| Cost | Higher material cost, lower labor cost | Lower material cost, higher labor cost |

| Durability | Good for residential use | Excellent for long-term use |

| Maintenance | Easy to disconnect and reuse | Permanent, requires cutting to remove |

| Materials Compatibility | Copper, PEX, CPVC pipes | Primarily copper pipes |

Introduction to Push-Fit and Sweat Connections

Push-fit connections utilize a simple, tool-free mechanism with a rubber O-ring seal, enabling quick and reliable pipe joining without soldering or adhesives. Sweat connections involve heating the pipe and fitting with a torch to melt and bond the metal, creating a durable, leak-proof joint ideal for copper plumbing systems. Both methods offer distinct advantages in installation speed and joint strength, making them suitable for various plumbing applications.

What Are Push-Fit Connections?

Push-fit connections are plumbing fixtures designed for quick, tool-free pipe joining by simply pushing the pipe into the fitting, creating a secure, watertight seal. These fittings often use an internal O-ring and metal teeth to grip and seal against various pipe materials such as copper, PEX, and CPVC. Push-fit connections provide versatility and ease of installation, eliminating the need for soldering, glue, or clamps, making them ideal for repairs and renovations.

What Are Sweat Connections?

Sweat connections, also known as soldered joints, involve joining copper pipes by heating the fitting and pipe with a torch and applying solder to create a watertight seal. This method requires careful preparation, including cleaning and flux application, to ensure a strong, durable bond resistant to leaks and corrosion. Commonly used in residential and commercial plumbing, sweat connections offer a permanent and reliable solution for copper pipe installations.

Installation Process: Push-Fit vs Sweat

Push-fit connections streamline the plumbing installation process by allowing pipes to be joined without tools, soldering, or adhesives, which reduces labor time and complexity. Sweat connections require cleaning, flux application, and precise heating to solder pipes together, demanding more skill and time but offering a durable, leak-proof joint ideal for high-pressure systems. Evaluating project scope, installer expertise, and system requirements helps determine whether the quick assembly of push-fit or the robust, permanent bond of sweat connections is more suitable.

Tools and Materials Required

Push-fit connections require minimal tools, typically just a pipe cutter and deburring tool, allowing quick installation without soldering or adhesive. Sweat connections demand more specialized tools, including a propane torch, flux, solder, and cleaning brushes, to ensure a secure, leak-proof joint through heating and melting metal. The choice of materials varies as push-fit fittings often use plastic or metal-compatible bodies, while sweat fittings are traditionally copper-based for optimal soldering results.

Reliability and Durability Comparison

Push-fit connections offer high reliability with quick, tool-free installation and excellent resistance to leaks in residential plumbing systems. Sweat connections, welded using solder, provide superior long-term durability and strength, making them ideal for high-pressure and high-temperature applications. While push-fit fittings are convenient for repairs and modifications, sweat connections generally ensure a more permanent, enduring plumbing seal.

Cost Analysis: Push-Fit vs Sweat

Push-fit connections typically reduce labor costs due to faster installation times and minimal tooling requirements, making them a cost-effective choice for both DIY projects and professional plumbing. Sweat connections, while often less expensive in terms of raw materials, require skilled labor and more time, increasing overall installation expenses. When considering long-term maintenance and repair costs, push-fit fittings offer savings by simplifying replacement without soldering or pipe cutting.

Common Applications in Plumbing

Push-fit connections are commonly used in residential plumbing for quick repairs and installations involving copper, PEX, or CPVC pipes due to their ease of use and tool-free assembly. Sweat connections, typically made with copper pipes and fittings, are preferred in commercial and high-pressure systems where a strong, permanent, and leak-resistant joint is essential. Both methods serve crucial roles, but push-fit is favored for retrofit and DIY projects, while sweat connections dominate in new construction and professional plumbing installations.

Pros and Cons of Push-Fit and Sweat Connections

Push-fit connections offer quick installation with no need for soldering, making them ideal for DIY projects and repairs, while their potential vulnerability to leaks under high pressure is a notable drawback. Sweat connections provide a watertight, durable seal by soldering copper pipes together, ensuring long-term reliability but requiring specialized skills and equipment for installation. Both methods serve essential roles in plumbing fixtures, with push-fit prioritizing convenience and sweat connections prioritizing longevity and strength.

Choosing the Right Connection for Your Project

Push-fit connections offer quick, tool-free installation and are ideal for repairs or tight spaces, providing flexibility and a secure seal without soldering. Sweat connections require soldering, creating a strong, permanent bond that excels in high-pressure or high-temperature applications, making them suitable for long-term, professional plumbing installations. Selecting the right connection depends on project demands such as durability, installation speed, and the specific plumbing environment.

Push-fit connection vs Sweat connection Infographic

productdif.com

productdif.com