Cold chain distribution ensures food safety by maintaining products at controlled, low temperatures from production to delivery, preserving freshness and preventing spoilage. In contrast, ambient distribution handles foods that remain stable at room temperature, reducing logistical costs and complexity. Choosing between these methods depends on product sensitivity, shelf life requirements, and supply chain infrastructure.

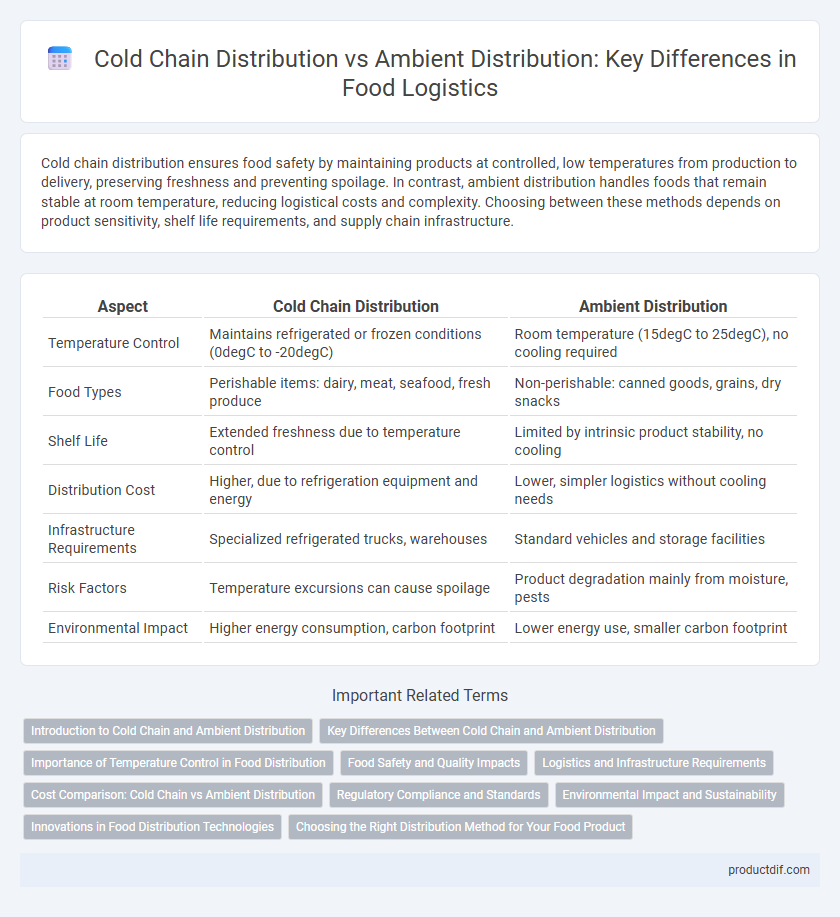

Table of Comparison

| Aspect | Cold Chain Distribution | Ambient Distribution |

|---|---|---|

| Temperature Control | Maintains refrigerated or frozen conditions (0degC to -20degC) | Room temperature (15degC to 25degC), no cooling required |

| Food Types | Perishable items: dairy, meat, seafood, fresh produce | Non-perishable: canned goods, grains, dry snacks |

| Shelf Life | Extended freshness due to temperature control | Limited by intrinsic product stability, no cooling |

| Distribution Cost | Higher, due to refrigeration equipment and energy | Lower, simpler logistics without cooling needs |

| Infrastructure Requirements | Specialized refrigerated trucks, warehouses | Standard vehicles and storage facilities |

| Risk Factors | Temperature excursions can cause spoilage | Product degradation mainly from moisture, pests |

| Environmental Impact | Higher energy consumption, carbon footprint | Lower energy use, smaller carbon footprint |

Introduction to Cold Chain and Ambient Distribution

Cold chain distribution involves the transportation and storage of perishable food products at controlled refrigerated temperatures to maintain freshness, safety, and extend shelf life, crucial for items like dairy, seafood, and pharmaceuticals. Ambient distribution refers to the handling of non-perishable goods that can be stored and transported at room temperature without compromising quality, such as canned goods, grains, and dry snacks. Choosing between cold chain and ambient distribution depends on the specific temperature sensitivity, product type, and regulatory requirements.

Key Differences Between Cold Chain and Ambient Distribution

Cold chain distribution maintains products at controlled low temperatures, typically between 2degC and 8degC, ensuring perishable goods like dairy, seafood, and pharmaceuticals remain safe and fresh. Ambient distribution transports products at room temperature, suitable for non-perishable items such as canned foods, grains, and dry goods, without specialized cooling requirements. The key differences lie in temperature control, packaging needs, and logistics complexity, where cold chain demands refrigerated vehicles and continuous monitoring, unlike ambient distribution which relies on standard shipping methods.

Importance of Temperature Control in Food Distribution

Temperature control in food distribution is critical to preserving food safety and quality, preventing microbial growth, and reducing spoilage. Cold chain distribution maintains perishable items like dairy, seafood, and fresh produce at consistent low temperatures, ensuring product freshness and extending shelf life. Ambient distribution suits shelf-stable goods but risks compromising sensitive foods if temperature fluctuations occur during transit.

Food Safety and Quality Impacts

Cold chain distribution ensures food safety and quality by maintaining consistent low temperatures, preventing microbial growth and spoilage in perishable products like dairy, meat, and seafood. Ambient distribution, suitable for non-perishable items such as canned foods and grains, carries higher risks of quality degradation and contamination when temperature fluctuations occur. Effective cold chain management reduces foodborne illnesses and extends shelf life, directly impacting consumer health and product integrity.

Logistics and Infrastructure Requirements

Cold chain distribution demands specialized refrigerated vehicles, temperature-controlled storage facilities, and continuous monitoring systems to maintain product integrity from origin to destination. Ambient distribution requires standard warehousing and transport solutions without climate control, reducing infrastructure complexity and costs. Logistics for cold chain involve stringent regulatory compliance and energy-intensive operations, while ambient distribution benefits from greater flexibility and lower operational risks.

Cost Comparison: Cold Chain vs Ambient Distribution

Cold chain distribution incurs higher costs due to refrigerated transport, specialized packaging, and energy consumption required to maintain product integrity. Ambient distribution offers lower expenses by utilizing standard shipping methods without temperature control, ideal for shelf-stable foods. Evaluating cost efficiency depends on product sensitivity, with cold chain essential for perishables despite increased operational expenses.

Regulatory Compliance and Standards

Cold chain distribution mandates strict adherence to regulatory compliance and industry standards such as FDA's Current Good Manufacturing Practices (cGMP) and the Food Safety Modernization Act (FSMA) to maintain product safety and quality through controlled temperatures. Ambient distribution, while less temperature-sensitive, still requires compliance with standards like HACCP (Hazard Analysis and Critical Control Points) to ensure safety during transportation and storage. Failure to meet these regulatory requirements in either system can result in food spoilage, legal penalties, and compromised consumer health.

Environmental Impact and Sustainability

Cold chain distribution, essential for preserving perishable food quality, consumes significantly more energy due to continuous refrigeration, contributing to higher greenhouse gas emissions compared to ambient distribution. Ambient distribution, which transports non-perishable or shelf-stable foods without refrigeration, offers lower carbon footprints and reduced energy consumption, enhancing overall sustainability. Optimizing packaging materials and transport logistics in both methods can further reduce environmental impacts and promote sustainable food supply chains.

Innovations in Food Distribution Technologies

Innovations in food distribution technologies have transformed cold chain distribution by integrating IoT sensors and real-time temperature monitoring, ensuring optimal freshness and safety for perishable goods. Ambient distribution benefits from advanced packaging materials and smart tracking systems that extend shelf life and enhance traceability without refrigeration. These technological advancements reduce food spoilage, lower logistics costs, and improve supply chain transparency in both cold chain and ambient distribution networks.

Choosing the Right Distribution Method for Your Food Product

Cold chain distribution maintains food products at precise refrigerated or frozen temperatures from production to delivery, ensuring freshness and preventing spoilage for perishable items like dairy, seafood, and fresh produce. Ambient distribution suits shelf-stable foods such as canned goods, dry snacks, and baked products, reducing transportation costs and logistical complexity by not requiring temperature control. Selecting the appropriate method depends on the product's sensitivity to temperature, shelf life, and safety requirements to optimize quality and minimize waste.

Cold Chain Distribution vs Ambient Distribution Infographic

productdif.com

productdif.com