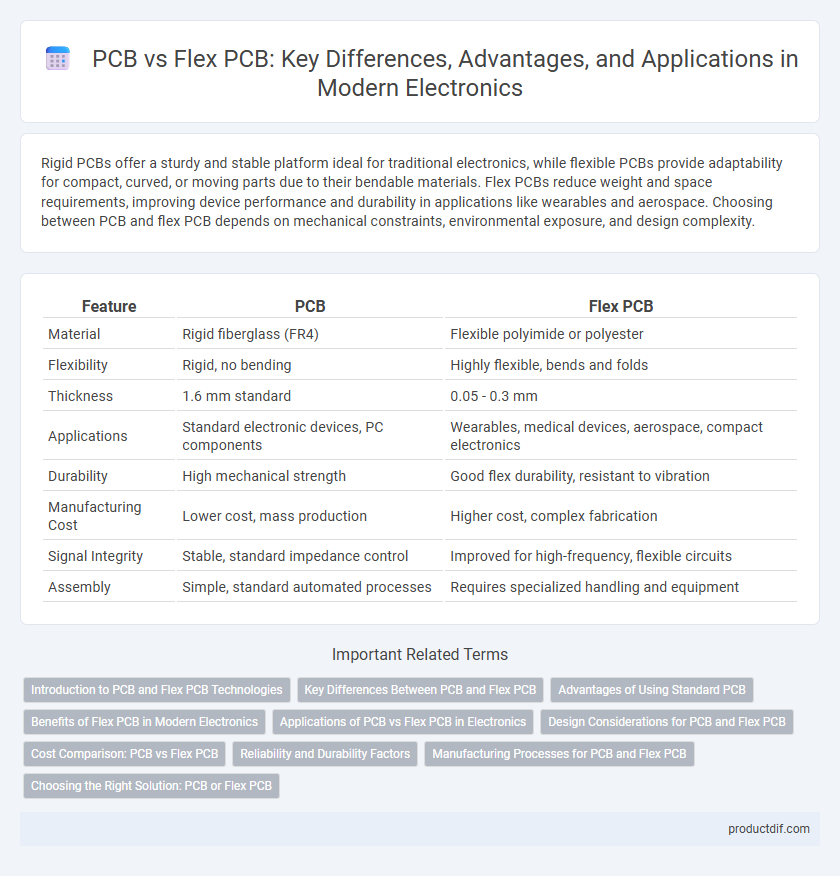

Rigid PCBs offer a sturdy and stable platform ideal for traditional electronics, while flexible PCBs provide adaptability for compact, curved, or moving parts due to their bendable materials. Flex PCBs reduce weight and space requirements, improving device performance and durability in applications like wearables and aerospace. Choosing between PCB and flex PCB depends on mechanical constraints, environmental exposure, and design complexity.

Table of Comparison

| Feature | PCB | Flex PCB |

|---|---|---|

| Material | Rigid fiberglass (FR4) | Flexible polyimide or polyester |

| Flexibility | Rigid, no bending | Highly flexible, bends and folds |

| Thickness | 1.6 mm standard | 0.05 - 0.3 mm |

| Applications | Standard electronic devices, PC components | Wearables, medical devices, aerospace, compact electronics |

| Durability | High mechanical strength | Good flex durability, resistant to vibration |

| Manufacturing Cost | Lower cost, mass production | Higher cost, complex fabrication |

| Signal Integrity | Stable, standard impedance control | Improved for high-frequency, flexible circuits |

| Assembly | Simple, standard automated processes | Requires specialized handling and equipment |

Introduction to PCB and Flex PCB Technologies

Printed Circuit Boards (PCBs) are rigid substrates composed of insulating materials such as fiberglass, with copper circuitry for electronic component interconnection, essential in most electronic devices. Flexible PCBs, made from polyimide or polyester films, offer bendable and lightweight alternatives that enable compact designs and improved durability under mechanical stress. These technologies differ mainly in material properties and application flexibility, influencing device design, reliability, and manufacturing complexity in electronics engineering.

Key Differences Between PCB and Flex PCB

Rigid PCBs are solid, durable circuit boards designed for fixed, static applications, while Flex PCBs are made from flexible substrate materials allowing bending and folding in compact or dynamic environments. Flex PCBs enable three-dimensional designs, reduce assembly weight, and improve space utilization compared to traditional PCBs, which are limited by their rigid structure. Key differences include material flexibility, design adaptability, manufacturing cost, and application suitability in electronics industries such as consumer devices and aerospace.

Advantages of Using Standard PCB

Standard PCBs offer superior mechanical stability and durability compared to flex PCBs, making them ideal for applications requiring robust and rigid circuit boards. They provide easier manufacturing processes and cost-effectiveness in high-volume production due to established fabrication techniques. Standard PCBs also facilitate simpler component placement and inspection, enhancing overall reliability in electronic assemblies.

Benefits of Flex PCB in Modern Electronics

Flex PCBs offer superior design versatility and space-saving advantages in modern electronics, allowing for complex, three-dimensional circuit layouts that rigid PCBs cannot achieve. Their lightweight and flexible materials enhance device durability by absorbing shocks and vibrations, making them ideal for wearable technology and compact gadgets. The ability to bend and fold reduces assembly time and costs, while improving electrical performance through shorter interconnects and fewer connectors.

Applications of PCB vs Flex PCB in Electronics

Rigid PCBs are widely utilized in consumer electronics, automotive control systems, and industrial machinery due to their durability and cost-effectiveness for complex circuit designs. Flex PCBs excel in applications requiring space-saving and dynamic movement, such as wearable devices, medical implants, and aerospace equipment where flexibility and lightweight structures are critical. The choice between PCB and Flex PCB depends on specific electronic design constraints including mechanical stress, space limitations, and environmental conditions.

Design Considerations for PCB and Flex PCB

Design considerations for PCB involve rigid substrates with fixed layouts, emphasizing thermal management, signal integrity, and mounting component density on multilayer boards. Flex PCB design prioritizes bend radius, dynamic flexibility, and material selection such as polyimide to withstand mechanical stress and maintain electrical performance. Effective thermal dissipation and mechanical durability remain critical factors in both PCB and flex PCB applications to ensure reliability in electronic assemblies.

Cost Comparison: PCB vs Flex PCB

Standard PCBs typically offer lower production costs due to established manufacturing processes and materials like FR4, making them cost-effective for high-volume, simple designs. Flex PCBs involve higher expenses because of specialized substrates such as polyimide and more complex fabrication techniques required for flexibility and three-dimensional installation. The cost difference becomes more significant in small volumes or intricate layouts where flex PCBs provide design advantages despite the premium price.

Reliability and Durability Factors

Flex PCBs offer superior reliability and durability compared to traditional rigid PCBs due to their ability to withstand repeated bending, vibration, and thermal stress without breaking or degrading. Materials like polyimide used in Flex PCBs provide enhanced thermal stability and resistance to chemicals, making them ideal for dynamic and harsh environments. Rigid PCBs, while robust under static conditions, are more prone to mechanical failure and delamination when subjected to continuous flexing or harsh mechanical stress.

Manufacturing Processes for PCB and Flex PCB

PCB manufacturing involves processes like photolithography, etching, drilling, and solder mask application on rigid substrates such as FR4, providing structural stability and high electrical performance. Flex PCB manufacturing requires additional steps including flexible substrate lamination, selective adhesive application, and controlled bending during production to maintain flexibility and durability under mechanical stress. Both methods demand precise layer alignment and copper patterning, but Flex PCBs use polyimide or polyester films to enable dynamic flexing without compromising circuit integrity.

Choosing the Right Solution: PCB or Flex PCB

Choosing between a traditional PCB and a Flex PCB depends on the application's space constraints, durability needs, and design complexity. Flex PCBs offer superior flexibility, lightweight characteristics, and better fit for compact or irregularly shaped devices, while rigid PCBs provide higher mechanical stability and cost efficiency for standard layouts. Evaluating factors such as environmental exposure, bending cycles, and production volume helps determine the optimal circuit board solution for electronics manufacturing.

PCB vs Flex PCB Infographic

productdif.com

productdif.com