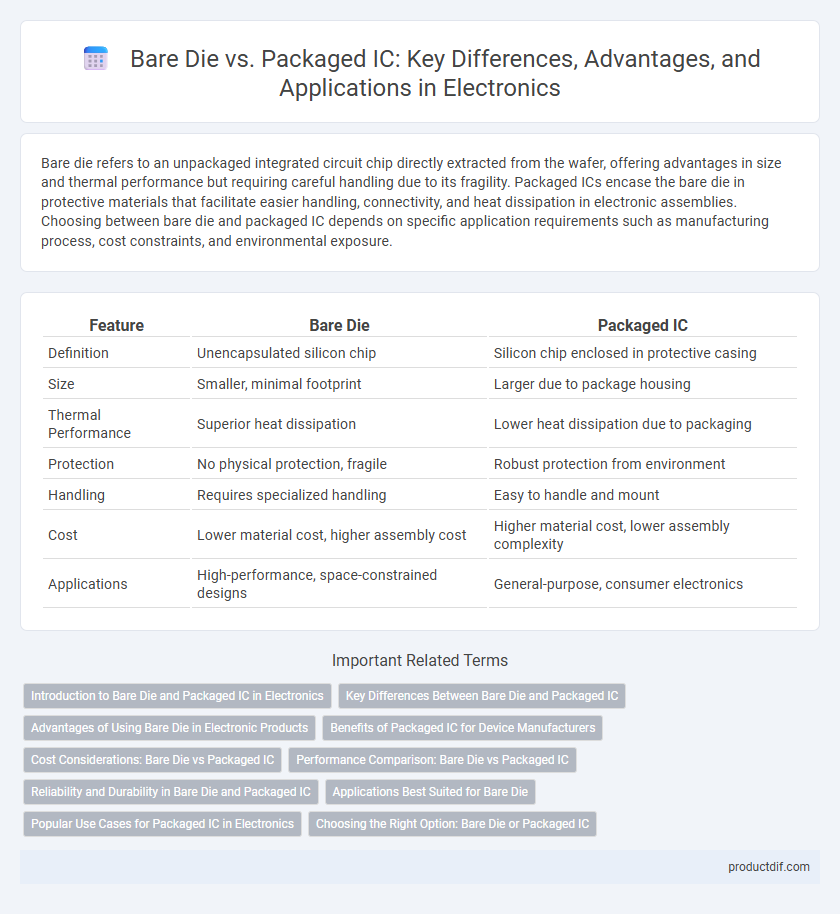

Bare die refers to an unpackaged integrated circuit chip directly extracted from the wafer, offering advantages in size and thermal performance but requiring careful handling due to its fragility. Packaged ICs encase the bare die in protective materials that facilitate easier handling, connectivity, and heat dissipation in electronic assemblies. Choosing between bare die and packaged IC depends on specific application requirements such as manufacturing process, cost constraints, and environmental exposure.

Table of Comparison

| Feature | Bare Die | Packaged IC |

|---|---|---|

| Definition | Unencapsulated silicon chip | Silicon chip enclosed in protective casing |

| Size | Smaller, minimal footprint | Larger due to package housing |

| Thermal Performance | Superior heat dissipation | Lower heat dissipation due to packaging |

| Protection | No physical protection, fragile | Robust protection from environment |

| Handling | Requires specialized handling | Easy to handle and mount |

| Cost | Lower material cost, higher assembly cost | Higher material cost, lower assembly complexity |

| Applications | High-performance, space-constrained designs | General-purpose, consumer electronics |

Introduction to Bare Die and Packaged IC in Electronics

Bare die refers to an unpackaged semiconductor chip without protective casing, commonly used in applications demanding minimal space and weight. Packaged ICs, in contrast, encase the die in a protective housing that facilitates easier handling, heat dissipation, and reliable electrical connections. The choice between bare die and packaged IC depends on factors such as thermal management, mechanical protection, and integration complexity in electronic device design.

Key Differences Between Bare Die and Packaged IC

Bare die refers to an unpackaged semiconductor chip that exposes the silicon wafer surface, offering minimal protection and direct access to electrical contacts, whereas packaged IC encases the die in a protective housing that facilitates easier handling, protection from environmental factors, and standard electrical connections. Bare die is primarily used in applications requiring high-density integration and custom assembly, while packaged ICs are favored for general-purpose use due to their durability and ease of installation on printed circuit boards (PCBs). Thermal performance and electrical parasitics differ significantly; bare die typically exhibits better thermal conductivity and lower inductance, whereas packaged ICs provide enhanced mechanical stability and simplified integration.

Advantages of Using Bare Die in Electronic Products

Bare die offers superior electrical performance due to minimal parasitic capacitance and inductance, leading to faster signal transmission and reduced latency in high-frequency applications. The compact size and absence of a package allow for higher component density and enhanced thermal dissipation, which improves reliability and efficiency in tightly integrated electronic products. Cost savings can be realized by eliminating packaging expenses, making bare die ideal for custom or space-constrained designs in advanced electronics manufacturing.

Benefits of Packaged IC for Device Manufacturers

Packaged ICs provide enhanced protection against environmental factors such as moisture, dust, and physical damage, improving device reliability and lifespan. Their standardized form factors simplify automated handling, assembly processes, and integration into printed circuit boards, reducing manufacturing costs and cycle times. Furthermore, packaged ICs often include built-in thermal management features, supporting better heat dissipation to maintain optimal device performance.

Cost Considerations: Bare Die vs Packaged IC

Bare die offers significant cost savings by eliminating packaging materials and processes, making it ideal for high-volume applications with stringent space constraints. Packaged ICs incur additional costs due to encapsulation, testing, and handling, but provide enhanced reliability and easier integration into standard printed circuit boards. Choosing between bare die and packaged ICs depends on balancing upfront manufacturing expenses against long-term performance and assembly efficiency requirements.

Performance Comparison: Bare Die vs Packaged IC

Bare die offers superior electrical performance due to minimized parasitic capacitance and inductance, resulting in faster signal transmission and reduced latency. Packaged ICs exhibit increased thermal resistance and signal degradation from packaging materials and lead frames, which can limit high-frequency performance. Bare die is preferred in high-speed, low-latency applications where maximum performance and limited physical space are critical.

Reliability and Durability in Bare Die and Packaged IC

Bare die exhibits higher vulnerability to environmental factors such as moisture, dust, and mechanical stress, compromising reliability and durability in harsh conditions. Packaged ICs provide enhanced protection through encapsulation, improving resistance to physical damage, corrosion, and thermal fluctuations, thereby extending operational lifespan. The choice between bare die and packaged IC often depends on the specific application requirements for robustness and long-term reliability.

Applications Best Suited for Bare Die

Bare die offers superior thermal performance and electrical characteristics, making it ideal for high-frequency RF applications, power amplifiers, and aerospace electronics where space and weight are critical. Its direct access to the silicon wafer enables custom integration in advanced sensor arrays and implantable medical devices requiring miniaturization and enhanced reliability. Bare die is also preferred in high-volume manufacturing settings where packaging costs need to be minimized without compromising performance.

Popular Use Cases for Packaged IC in Electronics

Packaged ICs are widely used in consumer electronics, automotive systems, and industrial equipment due to their enhanced protection and ease of handling. Their robust encapsulation ensures reliability in harsh environments, making them ideal for smartphones, laptops, and automotive control units. The plug-and-play nature of packaged ICs allows for simplified assembly and efficient integration in mass production.

Choosing the Right Option: Bare Die or Packaged IC

Choosing between bare die and packaged IC depends on the specific application requirements, such as space constraints, thermal management, and cost sensitivity. Bare die offers advantages in size reduction and thermal conductivity but requires advanced assembly processes and protection measures. Packaged ICs provide ease of handling, reliability, and standard interfacing, making them suitable for most consumer and industrial electronics.

Bare Die vs Packaged IC Infographic

productdif.com

productdif.com