Pin loom weaving offers compact, modular textile creation ideal for small projects and intricate designs, providing versatility in pattern experimentation. Rigid heddle weaving enables faster production with larger widths and even tension, making it suitable for creating garments and home decor with consistent weave density. Choosing between the two depends on project scale, desired texture, and ease of use in craft supply selection.

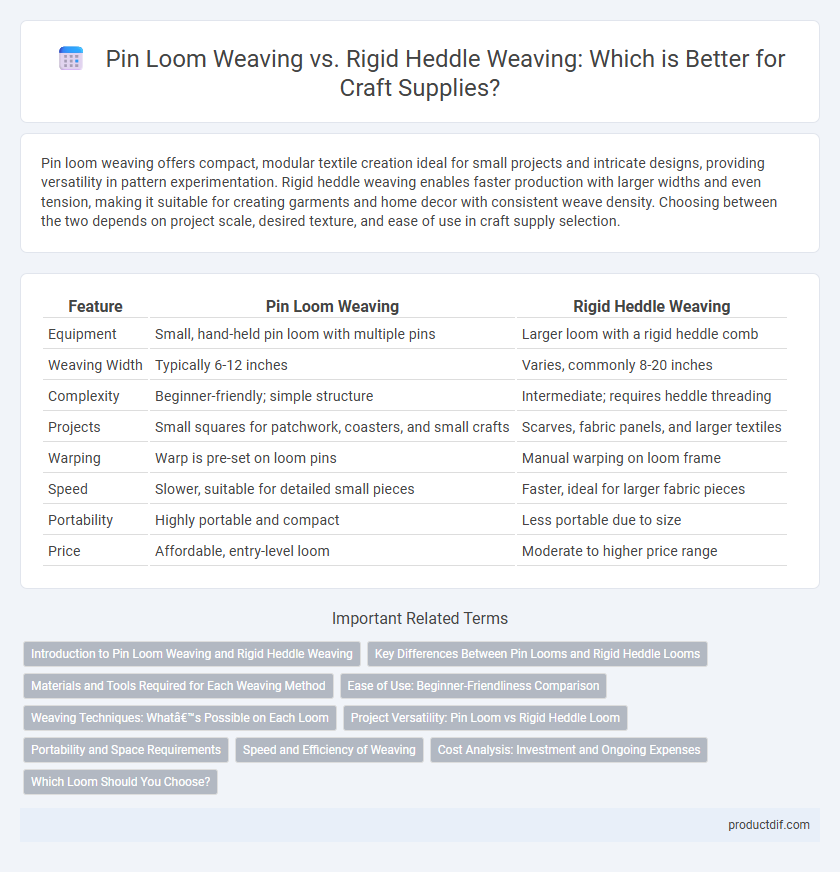

Table of Comparison

| Feature | Pin Loom Weaving | Rigid Heddle Weaving |

|---|---|---|

| Equipment | Small, hand-held pin loom with multiple pins | Larger loom with a rigid heddle comb |

| Weaving Width | Typically 6-12 inches | Varies, commonly 8-20 inches |

| Complexity | Beginner-friendly; simple structure | Intermediate; requires heddle threading |

| Projects | Small squares for patchwork, coasters, and small crafts | Scarves, fabric panels, and larger textiles |

| Warping | Warp is pre-set on loom pins | Manual warping on loom frame |

| Speed | Slower, suitable for detailed small pieces | Faster, ideal for larger fabric pieces |

| Portability | Highly portable and compact | Less portable due to size |

| Price | Affordable, entry-level loom | Moderate to higher price range |

Introduction to Pin Loom Weaving and Rigid Heddle Weaving

Pin loom weaving uses a small, handheld wooden or plastic frame with evenly spaced pegs to create miniature woven squares ideal for patchwork and small craft projects. Rigid heddle weaving employs a larger, flat loom with a heddle that lifts specific warp threads, enabling the creation of wider fabric for scarves, towels, and home decor. Both techniques offer unique weaving methods tailored for different project sizes, fiber types, and skill levels.

Key Differences Between Pin Looms and Rigid Heddle Looms

Pin loom weaving uses small, portable frames with pins that create tightly woven, intricate patterns ideal for small projects like coasters and samples, while rigid heddle weaving involves a larger loom with a heddle that simplifies the shedding process, making it faster and more efficient for producing wider, continuous fabric. Pin looms offer greater flexibility in shape and size but require more manual control over tension and pattern complexity, whereas rigid heddle looms provide consistent tension and allow for quicker weaving of larger textile pieces. The choice between pin loom and rigid heddle weaving depends mainly on project scale, fabric width, and desired weaving speed.

Materials and Tools Required for Each Weaving Method

Pin loom weaving requires small, portable pin looms made of wood or plastic, along with yarn or thread suitable for tight weaving patterns, making it ideal for crafting small textiles like coasters or mini rugs. Rigid heddle weaving involves a larger loom frame equipped with a heddle that controls warp threads, demanding materials such as warp and weft yarns with various textures and weights, suitable for creating wider fabric pieces like scarves and shawls. Both methods need basic tools like yarn needles and scissors, but rigid heddle weaving typically requires more space and investment in a loom, while pin looms are favored for their accessibility and compactness.

Ease of Use: Beginner-Friendliness Comparison

Pin loom weaving offers exceptional ease of use for beginners due to its compact size and straightforward design, requiring minimal setup and allowing quick projects like small squares or coasters. Rigid heddle weaving provides more versatility and larger fabric creation but involves a steeper learning curve with complex threading and tension adjustments. For beginners prioritizing simplicity and immediate results, pin loom weaving is typically more accessible, while rigid heddle weaving suits those ready to invest time mastering techniques for larger textiles.

Weaving Techniques: What’s Possible on Each Loom

Pin loom weaving allows for creating small, modular squares that can be joined into larger projects, ideal for intricate patterns and colorwork in compact designs. Rigid heddle weaving supports continuous lengths of fabric and enables a wider range of weave structures such as tabby, twill, and double weave, making it suitable for functional textiles like scarves and placemats. Each loom offers distinct advantages in weaving techniques, with pin looms excelling in modular, detailed work and rigid heddle looms enabling efficiency and versatility in fabric production.

Project Versatility: Pin Loom vs Rigid Heddle Loom

Pin loom weaving enables highly detailed small-scale projects ideal for intricate patterns and modular designs, making it perfect for crafting unique, compact textiles. Rigid heddle weaving offers greater project versatility by accommodating wider fabrics and continuous lengths, suited for scarves, placemats, and larger home decor items. The rigid heddle loom supports faster weaving and varied yarn types, expanding its applications compared to the more specialized pin loom.

Portability and Space Requirements

Pin loom weaving offers exceptional portability due to its compact, lightweight design, making it ideal for travel and small workspaces. Rigid heddle weaving requires a larger, stationary loom that demands more space, suitable for dedicated crafting areas. The minimal setup of pin looms contrasts with the rigid heddle loom's need for a stable, flat surface, influencing the choice based on workspace constraints and mobility needs.

Speed and Efficiency of Weaving

Pin loom weaving offers precise control over small-scale projects, enabling intricate designs with minimal setup, but it is generally slower due to manual handling of each weaving step. Rigid heddle weaving significantly increases speed and efficiency by automating heddle movement and allowing continuous weaving on larger widths, making it ideal for rapid production of scarves, bands, and fabric panels. Efficiency in rigid heddle looms comes from their integrated heddle system and shuttle mechanism, reducing time spent on yarn tension adjustments and warp preparation compared to pin looms.

Cost Analysis: Investment and Ongoing Expenses

Pin loom weaving requires a lower initial investment with basic pin loom frames costing around $10 to $30, making it accessible for beginners. Rigid heddle looms can range from $150 to $600 depending on size and brand, reflecting a higher upfront cost but offering greater versatility for complex projects. Ongoing expenses for pin loom users include replacement pins and basic yarns, whereas rigid heddle weaving often involves additional accessories and maintenance tools, raising long-term costs.

Which Loom Should You Choose?

Choosing between pin loom weaving and rigid heddle weaving depends on the desired project size and complexity; pin looms offer portability and detailed patchwork ideal for small, intricate designs, while rigid heddle looms enable faster production of larger, continuous fabrics with varied patterns. Pin looms are perfect for creating modular art pieces or samples, whereas rigid heddle looms provide versatility for scarves, blankets, and other substantial woven textiles. Consider the balance of portability, project scale, and weaving speed when selecting the ideal loom for your crafting needs.

Pin Loom Weaving vs Rigid Heddle Weaving Infographic

productdif.com

productdif.com