Small batch beverages emphasize artisanal quality and unique flavors, crafted with meticulous attention to detail and often sourced from premium ingredients. Mass production prioritizes efficiency and consistency, enabling large-scale output and widespread distribution at lower costs. Consumers seeking authentic taste experiences tend to favor small batch products, while those valuing convenience and affordability lean towards mass-produced options.

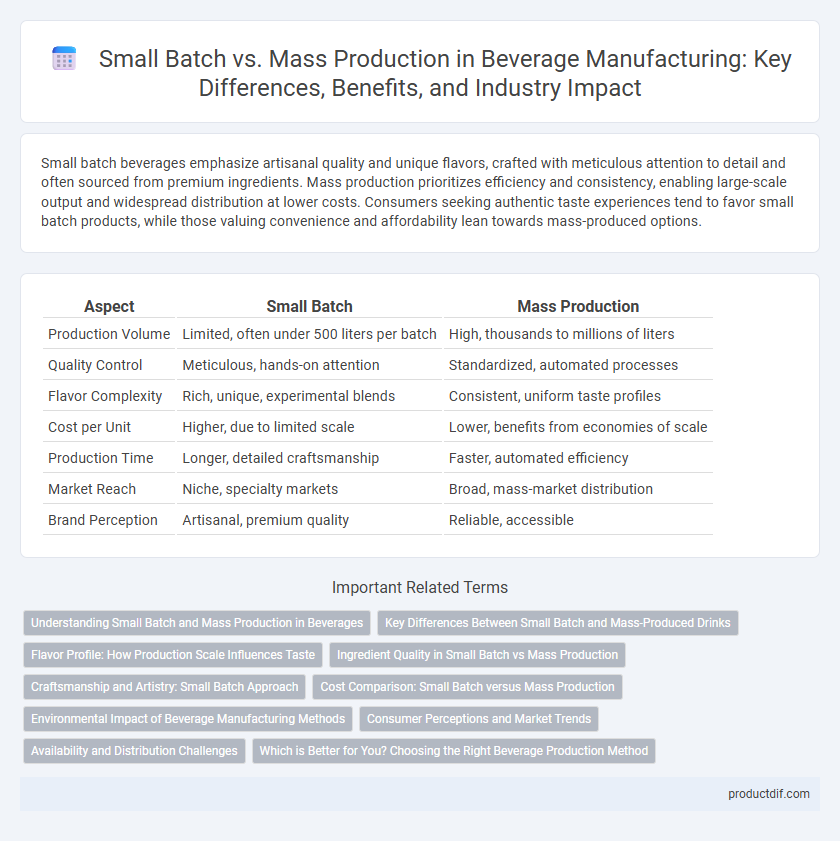

Table of Comparison

| Aspect | Small Batch | Mass Production |

|---|---|---|

| Production Volume | Limited, often under 500 liters per batch | High, thousands to millions of liters |

| Quality Control | Meticulous, hands-on attention | Standardized, automated processes |

| Flavor Complexity | Rich, unique, experimental blends | Consistent, uniform taste profiles |

| Cost per Unit | Higher, due to limited scale | Lower, benefits from economies of scale |

| Production Time | Longer, detailed craftsmanship | Faster, automated efficiency |

| Market Reach | Niche, specialty markets | Broad, mass-market distribution |

| Brand Perception | Artisanal, premium quality | Reliable, accessible |

Understanding Small Batch and Mass Production in Beverages

Small batch beverage production emphasizes quality, craftsmanship, and unique flavors by producing limited quantities with meticulous attention to detail. Mass production focuses on efficiency and consistency, enabling large-scale output through automated processes and standardized recipes. Understanding these methods helps consumers and businesses appreciate the trade-offs between artisanal qualities and widespread availability in the beverage industry.

Key Differences Between Small Batch and Mass-Produced Drinks

Small batch drinks emphasize artisanal quality, unique flavors, and limited quantities, often crafted with locally sourced ingredients and attention to detail. Mass-produced beverages are manufactured on a large scale using automated processes, ensuring consistency, lower cost, and widespread availability. Key differences include scalability, ingredient sourcing, production methods, and consumer experience, with small batch catering to niche markets versus mass production targeting broad distribution.

Flavor Profile: How Production Scale Influences Taste

Small batch beverages often exhibit complex and nuanced flavor profiles due to meticulous ingredient selection and handcrafted techniques, enhancing unique aromatic and taste characteristics. Mass production typically emphasizes consistency and efficiency, which can lead to more uniform but less distinctive flavors, as processes are standardized and ingredients may be simplified. The scale of production directly impacts microbial activity, fermentation time, and ingredient quality, all of which play critical roles in defining the final taste experience.

Ingredient Quality in Small Batch vs Mass Production

Small batch beverage production prioritizes high-quality, often locally sourced ingredients, resulting in superior flavor complexity and freshness compared to mass production. In contrast, mass production frequently uses cost-effective, standardized ingredients to maintain consistency and scale, which can compromise ingredient quality. This difference significantly impacts the taste profile and consumer perception of artisanal versus mass-produced beverages.

Craftsmanship and Artistry: Small Batch Approach

Small batch beverage production emphasizes craftsmanship and artistry by allowing artisans to meticulously control each step of the process, resulting in unique flavors and superior quality. This approach fosters innovation and personalization, as producers can experiment with ingredients and techniques that highlight distinct sensory profiles. Small batch methods prioritize authenticity and attention to detail, setting them apart from the uniformity typical of mass production.

Cost Comparison: Small Batch versus Mass Production

Small batch beverage production typically incurs higher per-unit costs due to limited economies of scale, specialized ingredients, and artisanal processes. Mass production reduces costs significantly through bulk purchasing, automated machinery, and streamlined distribution, enabling lower price points and higher profit margins. However, small batch producers often justify higher prices with quality differentiation and niche market appeal.

Environmental Impact of Beverage Manufacturing Methods

Small batch beverage production typically results in a lower environmental footprint due to reduced resource consumption and localized sourcing, which minimizes transportation emissions. Mass production, while efficient at scale, often involves large energy inputs and generates significant waste, contributing to higher carbon emissions and water usage. Sustainable practices in both methods, such as using renewable energy and optimizing supply chains, are essential to minimize environmental impact in beverage manufacturing.

Consumer Perceptions and Market Trends

Small batch beverages are often perceived as higher quality and more artisanal, appealing to consumers seeking unique flavors and authentic experiences. Mass production focuses on affordability and consistency, which drives widespread market availability and meets mainstream demand. Current market trends show a growing preference for craft and specialty drinks, signaling a shift towards personalized and premium beverage options.

Availability and Distribution Challenges

Small batch beverages often face limited availability due to smaller production volumes and localized distribution networks, restricting access to niche markets and specialty retailers. Mass production enables widespread availability through extensive distribution channels, including national retailers and online platforms, but may compromise unique qualities associated with small batch products. Distribution challenges for small batches include scaling logistics and meeting diverse regulatory requirements, while mass production benefits from established supply chains and distribution efficiencies.

Which is Better for You? Choosing the Right Beverage Production Method

Small batch beverage production offers superior quality control, unique flavor profiles, and artisanal craftsmanship ideal for consumers seeking distinct and premium products. Mass production ensures consistent taste, affordability, and wide availability, catering to high demand and cost-conscious buyers. Choosing the right beverage production method depends on personal preferences for quality, exclusivity, and budget.

Small Batch vs Mass Production Infographic

productdif.com

productdif.com