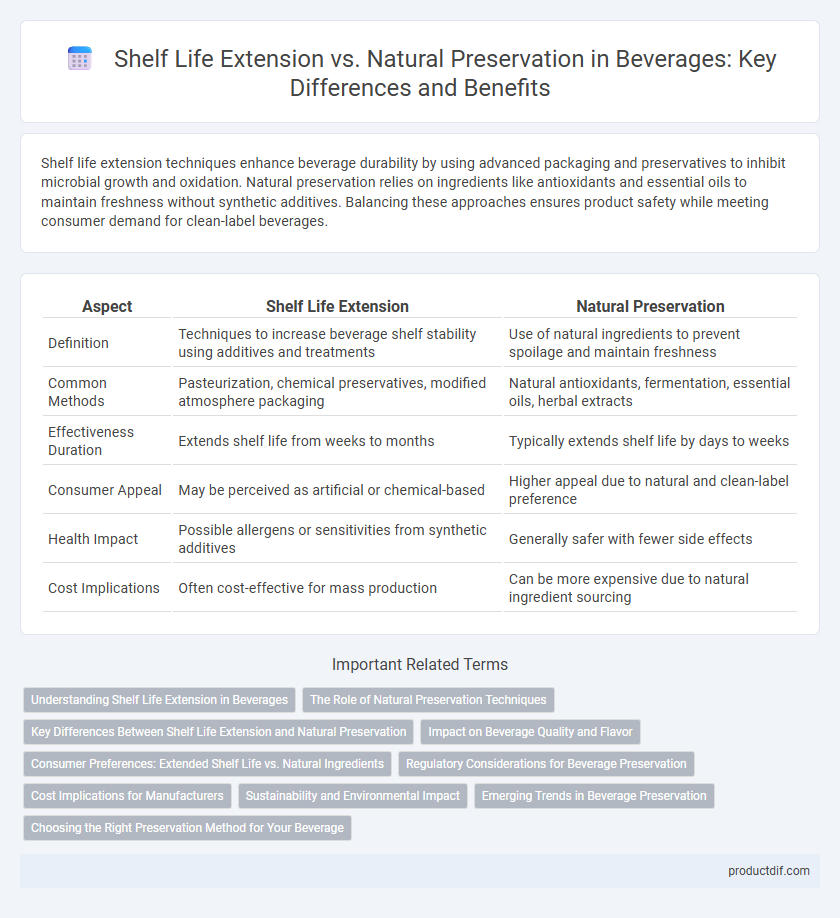

Shelf life extension techniques enhance beverage durability by using advanced packaging and preservatives to inhibit microbial growth and oxidation. Natural preservation relies on ingredients like antioxidants and essential oils to maintain freshness without synthetic additives. Balancing these approaches ensures product safety while meeting consumer demand for clean-label beverages.

Table of Comparison

| Aspect | Shelf Life Extension | Natural Preservation |

|---|---|---|

| Definition | Techniques to increase beverage shelf stability using additives and treatments | Use of natural ingredients to prevent spoilage and maintain freshness |

| Common Methods | Pasteurization, chemical preservatives, modified atmosphere packaging | Natural antioxidants, fermentation, essential oils, herbal extracts |

| Effectiveness Duration | Extends shelf life from weeks to months | Typically extends shelf life by days to weeks |

| Consumer Appeal | May be perceived as artificial or chemical-based | Higher appeal due to natural and clean-label preference |

| Health Impact | Possible allergens or sensitivities from synthetic additives | Generally safer with fewer side effects |

| Cost Implications | Often cost-effective for mass production | Can be more expensive due to natural ingredient sourcing |

Understanding Shelf Life Extension in Beverages

Shelf life extension in beverages involves advanced techniques such as pasteurization, ultra-high temperature processing (UHT), and aseptic packaging to inhibit microbial growth and preserve flavor and nutritional quality. These methods significantly delay spoilage compared to natural preservation, which relies on intrinsic ingredients like antioxidants and fermentation but offers limited protection against contaminants. Optimizing shelf life extension enhances product safety, reduces waste, and supports distribution efficiency in the beverage industry.

The Role of Natural Preservation Techniques

Natural preservation techniques play a crucial role in extending the shelf life of beverages by utilizing organic methods such as fermentation, pasteurization, and the inclusion of natural antimicrobials like essential oils and plant extracts. These methods inhibit microbial growth and oxidative spoilage without relying on synthetic preservatives, thereby maintaining the beverage's nutritional value and sensory properties. Emphasizing natural preservation aligns with consumer demand for clean-label products and supports sustainable production practices within the beverage industry.

Key Differences Between Shelf Life Extension and Natural Preservation

Shelf life extension in beverages typically involves artificial additives, chemical preservatives, and advanced packaging technologies designed to inhibit microbial growth and oxidation, thereby prolonging product freshness beyond its natural span. Natural preservation relies on ingredients such as antioxidants, essential oils, organic acids, or fermentation processes to maintain quality without synthetic chemicals. The key differences lie in the methods used, the impact on flavor profiles, consumer perception of ingredient safety, and regulatory approvals governing additive use.

Impact on Beverage Quality and Flavor

Shelf life extension techniques such as pasteurization and chemical preservatives often impact beverage quality by altering taste profiles and reducing the intensity of natural flavors. Natural preservation methods, including fermentation and the use of antioxidants like Vitamin C, maintain original flavor characteristics while prolonging freshness. Balancing shelf life extension with preservation of sensory attributes is crucial for consumer satisfaction and product integrity in the beverage industry.

Consumer Preferences: Extended Shelf Life vs. Natural Ingredients

Consumers increasingly prefer beverages with natural ingredients, associating them with health benefits and clean-label appeal, which drives demand for naturally preserved products. However, extended shelf life achieved through advanced preservation technologies satisfies the need for convenience and reduced food waste, appealing to time-conscious buyers. Balancing these preferences challenges manufacturers to innovate solutions that maintain product freshness while highlighting natural preservation methods.

Regulatory Considerations for Beverage Preservation

Regulatory considerations for beverage preservation vary significantly between shelf life extension methods and natural preservation techniques, with authorities such as the FDA and EFSA requiring rigorous safety and efficacy data for synthetic additives. Natural preservatives like antioxidants and essential oils must comply with limits on permissible concentrations and labeling standards to avoid misleading health claims. Ensuring compliance with beverage-specific regulations, such as the Food Additives Regulation (EC) No 1333/2008 in the EU, is critical to market approval and consumer safety.

Cost Implications for Manufacturers

Shelf life extension techniques often involve advanced chemical treatments or packaging innovations that increase production costs, impacting manufacturers' profitability margins. Natural preservation methods, such as using organic antioxidants or fermentation, may reduce reliance on synthetic additives but sometimes require more expensive raw materials or specialized processes, influencing overall costs. Manufacturers must balance initial investment with long-term savings from reduced spoilage and enhanced product appeal when choosing between shelf life extension and natural preservation strategies.

Sustainability and Environmental Impact

Shelf life extension through advanced packaging technologies reduces food and beverage waste by preserving product quality longer, thereby lowering environmental impact associated with resource extraction and manufacturing. Natural preservation methods, such as using plant-based antioxidants and fermentation, offer sustainable alternatives by minimizing chemical additives and supporting biodegradable packaging solutions. Balancing these approaches enhances sustainability by optimizing product longevity while reducing reliance on synthetic preservatives and non-recyclable materials.

Emerging Trends in Beverage Preservation

Emerging trends in beverage preservation emphasize natural preservation methods such as plant-based antimicrobials, fermentation, and high-pressure processing to extend shelf life while maintaining product quality. These techniques reduce reliance on synthetic preservatives and align with consumer demand for clean-label and minimally processed beverages. Innovations in natural preservation contribute to sustainability by minimizing chemical additives and enhancing the beverage industry's eco-friendly credentials.

Choosing the Right Preservation Method for Your Beverage

Choosing the right preservation method for your beverage depends on the desired shelf life, product quality, and consumer preferences. Shelf life extension techniques such as pasteurization, UV treatment, and chemical preservatives offer longer durability but may impact flavor and nutritional value. Natural preservation methods, including fermentation, cold storage, and natural antioxidants, maintain authenticity and clean-label appeal while typically providing shorter shelf stability.

Shelf Life Extension vs Natural Preservation Infographic

productdif.com

productdif.com