Cold fill and hot fill are two primary methods used in beverage PET bottle production, each influencing product quality and shelf life. Cold fill involves filling beverages at room temperature, requiring sterilized conditions to prevent contamination, while hot fill uses high temperatures to sterilize both the bottle and the beverage, ensuring longer shelf stability. Choosing between cold fill and hot fill depends on the beverage type, desired shelf life, and packaging equipment compatibility.

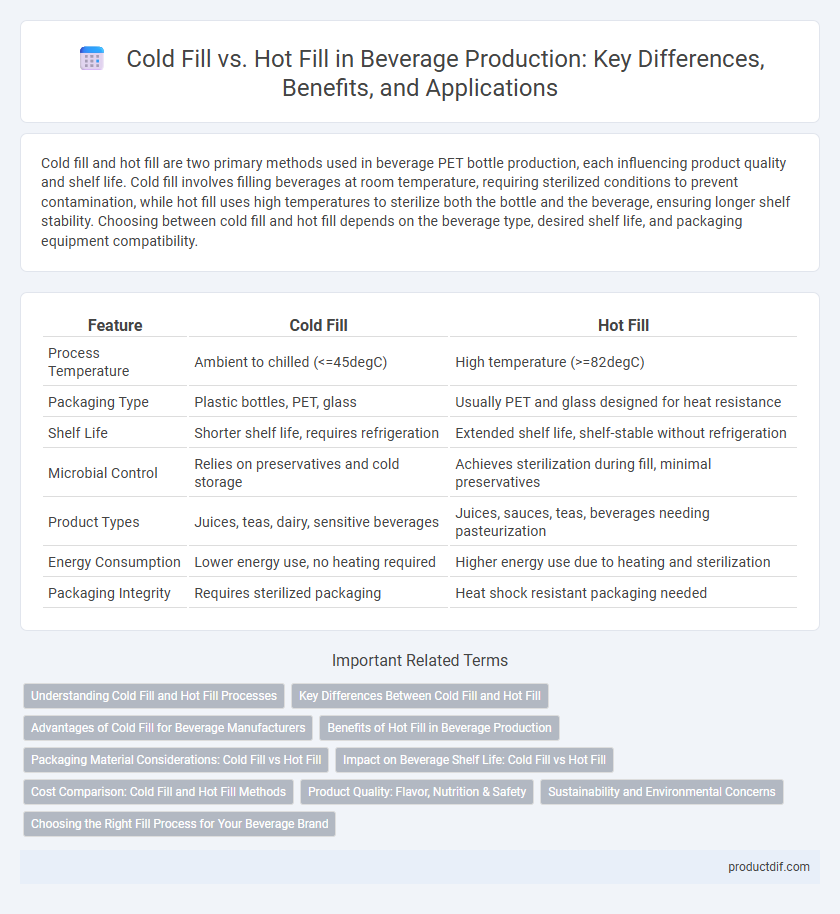

Table of Comparison

| Feature | Cold Fill | Hot Fill |

|---|---|---|

| Process Temperature | Ambient to chilled (<=45degC) | High temperature (>=82degC) |

| Packaging Type | Plastic bottles, PET, glass | Usually PET and glass designed for heat resistance |

| Shelf Life | Shorter shelf life, requires refrigeration | Extended shelf life, shelf-stable without refrigeration |

| Microbial Control | Relies on preservatives and cold storage | Achieves sterilization during fill, minimal preservatives |

| Product Types | Juices, teas, dairy, sensitive beverages | Juices, sauces, teas, beverages needing pasteurization |

| Energy Consumption | Lower energy use, no heating required | Higher energy use due to heating and sterilization |

| Packaging Integrity | Requires sterilized packaging | Heat shock resistant packaging needed |

Understanding Cold Fill and Hot Fill Processes

Cold fill and hot fill are two primary beverage packaging methods that influence product safety, shelf life, and quality. Hot fill involves heating the beverage to 85-95degC to sterilize it before packaging, ensuring microbial stability and extended shelf life without preservatives. Cold fill processes package beverages at ambient temperatures, relying on aseptic conditions and preservatives to maintain freshness, typically used for products sensitive to heat like juices and carbonated drinks.

Key Differences Between Cold Fill and Hot Fill

Cold fill involves packaging beverages at low temperatures to preserve freshness and flavor, mainly used for carbonated drinks and juices requiring minimal pasteurization. Hot fill uses high temperatures to sterilize the product and container, ideal for products needing extended shelf life without preservatives, such as fruit juices and teas. Key differences include the temperature of the filling process, packaging materials compatibility, and the impact on flavor stability and microbial safety.

Advantages of Cold Fill for Beverage Manufacturers

Cold fill technology preserves beverage flavor and nutrient integrity by avoiding heat exposure, ensuring a fresher taste and higher product quality. It reduces energy consumption during production, leading to lower operational costs and a smaller carbon footprint for manufacturers. Additionally, cold fill packaging maintains container integrity and extends shelf life without the risk of heat damage or altered physical properties.

Benefits of Hot Fill in Beverage Production

Hot fill technology in beverage production enhances shelf life by effectively sterilizing both the product and container, reducing microbial contamination without preservatives. This method preserves flavor and nutritional quality by minimizing oxidation and maintaining product integrity at higher temperatures. Hot fill also supports packaging versatility, allowing the use of lightweight, recyclable containers that improve sustainability and reduce shipping costs.

Packaging Material Considerations: Cold Fill vs Hot Fill

Cold fill packaging requires materials with low heat tolerance such as PET or glass to maintain product integrity and prevent deformation, while hot fill demands heat-resistant containers like polypropylene or specially treated glass to withstand temperatures typically above 85degC. Hot fill containers often feature thicker walls and enhanced sealing properties to tolerate thermal stress and ensure shelf stability without preservatives. Material selection directly impacts product safety, shelf life, and visual appeal, with cold fill favoring lightweight, recyclable options and hot fill prioritizing durability and heat resistance.

Impact on Beverage Shelf Life: Cold Fill vs Hot Fill

Cold fill processes often lead to shorter beverage shelf life due to minimal microbial inactivation and potential contamination risks. Hot fill techniques extend shelf life by sterilizing both the beverage and container, effectively reducing microbial load. Selecting the appropriate fill method depends on the beverage's pH, heat sensitivity, and desired durability on the shelf.

Cost Comparison: Cold Fill and Hot Fill Methods

Cold fill methods generally incur lower energy costs due to the absence of heating requirements, making them more economical for large-scale beverage production. Hot fill processes demand higher energy input for sterilization and heating, leading to increased utility expenses and longer production cycles. Packaging costs may also vary as hot fill often requires heat-resistant containers, which can elevate overall production expenses compared to cold fill.

Product Quality: Flavor, Nutrition & Safety

Cold fill preserves beverage flavor by minimizing heat exposure, maintaining delicate aroma compounds and natural freshness, while hot fill enhances microbial safety through pasteurization but can alter taste and reduce vitamin content. Nutritional quality is better retained in cold fill processes since heat-sensitive nutrients like vitamin C degrade less, whereas hot fill ensures extended shelf life and pathogen control. Safety concerns favor hot fill for its effective sterilization, but advanced cold fill technologies now balance microbial safety with superior flavor and nutrient retention.

Sustainability and Environmental Concerns

Cold fill packaging reduces energy consumption by eliminating the need to heat beverages for filling, resulting in lower carbon emissions compared to hot fill processes. Hot fill requires higher thermal energy, often increasing the overall environmental footprint due to greater fuel and resource use. Sustainable beverage production increasingly favors cold fill techniques to minimize water usage, energy demand, and packaging waste.

Choosing the Right Fill Process for Your Beverage Brand

Cold fill preserves the fresh taste and nutritional value of heat-sensitive beverages like juices and teas, making it ideal for products requiring a longer shelf life without preservatives. Hot fill sterilizes both the product and the container through high-temperature filling, ensuring microbial safety for acidic beverages such as fruit punches and energy drinks. Selecting the right fill process depends on your beverage's acidity, shelf life requirements, and packaging material compatibility.

Cold Fill vs Hot Fill Infographic

productdif.com

productdif.com