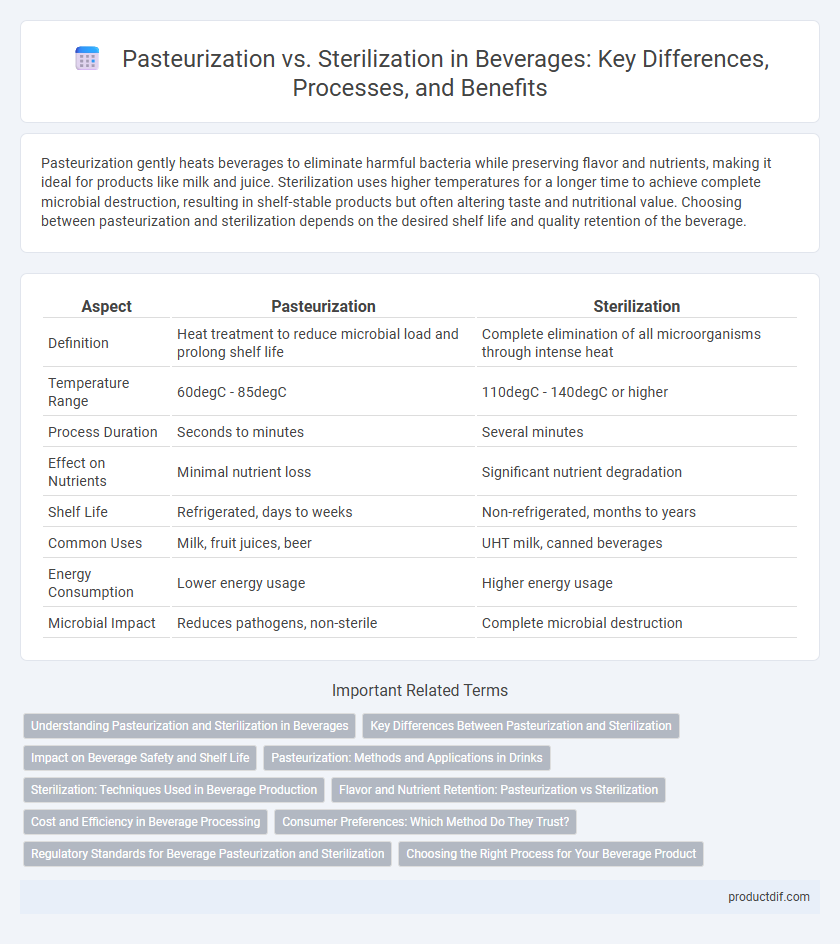

Pasteurization gently heats beverages to eliminate harmful bacteria while preserving flavor and nutrients, making it ideal for products like milk and juice. Sterilization uses higher temperatures for a longer time to achieve complete microbial destruction, resulting in shelf-stable products but often altering taste and nutritional value. Choosing between pasteurization and sterilization depends on the desired shelf life and quality retention of the beverage.

Table of Comparison

| Aspect | Pasteurization | Sterilization |

|---|---|---|

| Definition | Heat treatment to reduce microbial load and prolong shelf life | Complete elimination of all microorganisms through intense heat |

| Temperature Range | 60degC - 85degC | 110degC - 140degC or higher |

| Process Duration | Seconds to minutes | Several minutes |

| Effect on Nutrients | Minimal nutrient loss | Significant nutrient degradation |

| Shelf Life | Refrigerated, days to weeks | Non-refrigerated, months to years |

| Common Uses | Milk, fruit juices, beer | UHT milk, canned beverages |

| Energy Consumption | Lower energy usage | Higher energy usage |

| Microbial Impact | Reduces pathogens, non-sterile | Complete microbial destruction |

Understanding Pasteurization and Sterilization in Beverages

Pasteurization in beverages involves heating liquids to a specific temperature below boiling to kill harmful microorganisms while preserving flavor and nutritional value. Sterilization uses higher temperatures for a longer duration to eliminate all microbial life, resulting in extended shelf life but potentially altering taste and nutrients. Selecting between pasteurization and sterilization depends on the beverage type, desired shelf stability, and quality retention.

Key Differences Between Pasteurization and Sterilization

Pasteurization involves heating beverages to temperatures between 60degC and 85degC for a short time to kill most pathogenic bacteria, preserving flavor and nutrients while extending shelf life; sterilization uses higher temperatures above 100degC, often through autoclaving or UHT (Ultra-High Temperature) processes, to eliminate all microorganisms and spores, resulting in longer shelf stability but potential changes in taste and nutritional value. Pasteurized beverages require refrigeration due to incomplete microbial kill, whereas sterilized beverages are shelf-stable without refrigeration. Choosing between pasteurization and sterilization depends on the desired shelf life, flavor retention, and safety standards for the specific beverage product.

Impact on Beverage Safety and Shelf Life

Pasteurization effectively reduces pathogenic microorganisms in beverages, enhancing safety while preserving flavor, but typically allows for a shorter shelf life compared to sterilization. Sterilization eliminates all microbes, resulting in beverages that are microbiologically stable for extended periods without refrigeration but may alter taste and nutritional content. Selecting between pasteurization and sterilization depends on the desired balance between safety, shelf life, and sensory quality in beverage production.

Pasteurization: Methods and Applications in Drinks

Pasteurization in beverages involves heating liquids like milk, fruit juices, and beer to specific temperatures, usually between 60degC and 85degC, to eliminate pathogenic microorganisms while preserving flavor and nutrients. Common methods include batch pasteurization, where liquids are heated in large tanks for about 15-30 seconds, and continuous flow pasteurization that uses high temperatures for a few seconds to ensure safety and extend shelf life. This technique is widely applied in dairy products, fruit juices, and soft drinks to maintain quality without the harsher effects of sterilization, which involves higher temperatures that can alter taste and nutritional value.

Sterilization: Techniques Used in Beverage Production

Sterilization techniques in beverage production include ultra-high temperature (UHT) processing, microfiltration, and high-pressure processing (HPP), which effectively eliminate microbial contaminants while preserving flavor and nutritional quality. UHT involves heating beverages to temperatures above 135degC for a few seconds, ensuring shelf-stable products without refrigeration. High-pressure processing uses intense pressure up to 600 MPa to inactivate pathogens and spoilage organisms, maintaining fresh-like sensory attributes in juices and dairy beverages.

Flavor and Nutrient Retention: Pasteurization vs Sterilization

Pasteurization preserves more of the beverage's natural flavor and nutrients by using moderate heat to eliminate harmful microorganisms without significantly altering taste or nutritional content. Sterilization involves higher temperatures that extend shelf life but often cause noticeable changes in flavor and a reduction in heat-sensitive vitamins like vitamin C and B-complex. Choosing pasteurization over sterilization is preferred for maintaining sensory quality and nutrient integrity in beverages such as juices and dairy products.

Cost and Efficiency in Beverage Processing

Pasteurization in beverage processing offers cost-effective heat treatment by using lower temperatures and shorter times, resulting in energy savings and faster production cycles. Sterilization involves higher temperatures and longer durations, increasing operational costs but ensuring extended shelf life and comprehensive microbial inactivation. Efficiency depends on beverage type and shelf-life requirements; pasteurization suits perishable drinks with moderate safety needs, while sterilization is essential for long-lasting, shelf-stable beverages despite higher expenses.

Consumer Preferences: Which Method Do They Trust?

Consumers tend to trust pasteurization more due to its long-standing use and perception of preserving natural flavors in beverages. Sterilization, while offering a longer shelf life, is often viewed skeptically because of concerns over taste alteration and chemical changes. Market surveys consistently show that preference leans toward pasteurized products for freshness and safety reassurance.

Regulatory Standards for Beverage Pasteurization and Sterilization

Regulatory standards for beverage pasteurization typically mandate precise temperature-time combinations to effectively reduce pathogens while preserving product quality, such as heating at 71.7degC for 15 seconds in high-temperature short-time (HTST) pasteurization. Sterilization standards require more rigorous conditions, often exceeding 121degC for 15 minutes, aiming for commercial sterility and extended shelf life, especially in low-acid beverages. Compliance with agencies like the FDA and USDA ensures that pasteurized and sterilized beverages meet safety criteria, prevent microbial contamination, and align with labeling requirements.

Choosing the Right Process for Your Beverage Product

Pasteurization preserves beverage flavor and nutritional value by applying mild heat to eliminate pathogens, ideal for products like milk and fruit juices requiring extended shelf life without altered taste. Sterilization uses higher temperatures to achieve complete microbial destruction, suitable for shelf-stable beverages such as canned coffee or UHT milk but may impact sensory qualities. Selecting the appropriate process depends on the beverage type, desired shelf life, and consumer expectations for freshness and safety.

Pasteurization vs Sterilization Infographic

productdif.com

productdif.com