High-Pressure Processing (HPP) preserves the freshness and nutritional quality of beverage PET products by using intense pressure to inactivate pathogens without heat, maintaining flavor and color. Aseptic Processing involves sterilizing both the beverage and the PET container separately before filling, ensuring extended shelf life but often subjecting the product to higher temperatures. Choosing between HPP and Aseptic Processing depends on product sensitivity, desired shelf life, and cost considerations in beverage PET packaging.

Table of Comparison

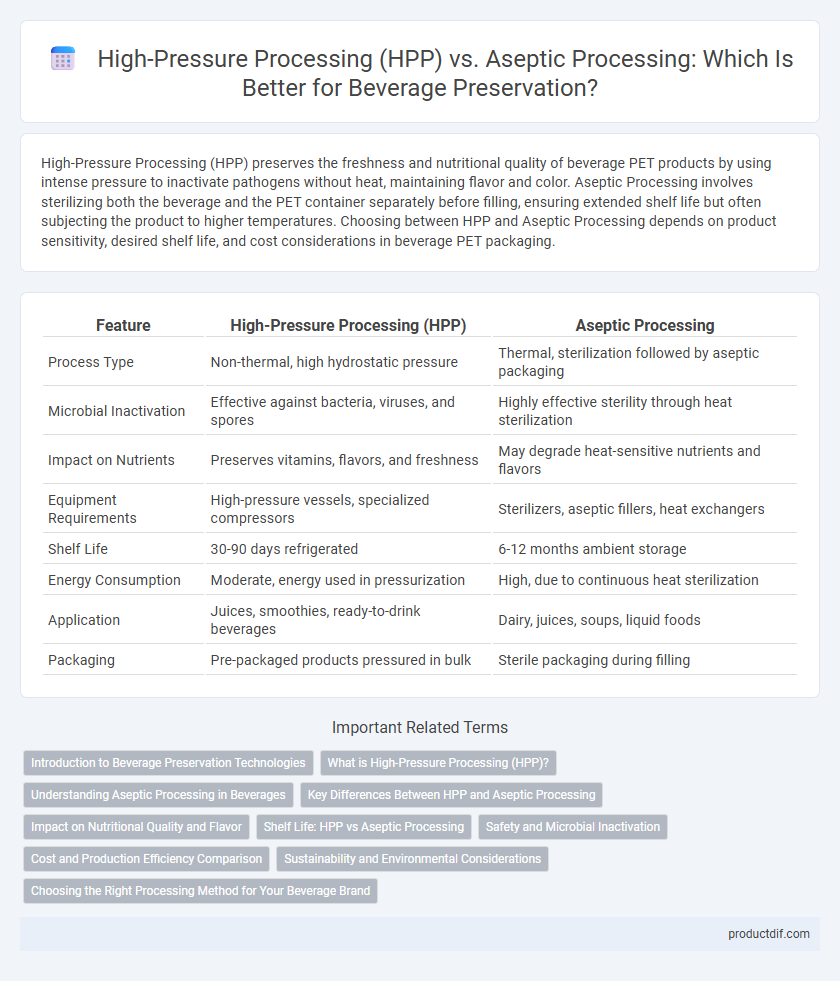

| Feature | High-Pressure Processing (HPP) | Aseptic Processing |

|---|---|---|

| Process Type | Non-thermal, high hydrostatic pressure | Thermal, sterilization followed by aseptic packaging |

| Microbial Inactivation | Effective against bacteria, viruses, and spores | Highly effective sterility through heat sterilization |

| Impact on Nutrients | Preserves vitamins, flavors, and freshness | May degrade heat-sensitive nutrients and flavors |

| Equipment Requirements | High-pressure vessels, specialized compressors | Sterilizers, aseptic fillers, heat exchangers |

| Shelf Life | 30-90 days refrigerated | 6-12 months ambient storage |

| Energy Consumption | Moderate, energy used in pressurization | High, due to continuous heat sterilization |

| Application | Juices, smoothies, ready-to-drink beverages | Dairy, juices, soups, liquid foods |

| Packaging | Pre-packaged products pressured in bulk | Sterile packaging during filling |

Introduction to Beverage Preservation Technologies

High-Pressure Processing (HPP) utilizes intense hydrostatic pressure to inactivate pathogens and extend shelf life without compromising beverage flavor or nutrient content. Aseptic Processing involves sterilizing both the beverage and packaging separately before filling, ensuring microbial safety and long shelf stability at ambient temperatures. Both technologies are critical for preserving freshness and quality in juices, dairy drinks, and ready-to-drink beverages.

What is High-Pressure Processing (HPP)?

High-Pressure Processing (HPP) is a non-thermal preservation technique that uses extremely high pressure, typically between 400 and 600 MPa, to inactivate microbes and enzymes in beverages without compromising flavor or nutritional value. This method extends shelf life and maintains the fresh taste of juices, smoothies, and other liquid products by preserving vitamins and antioxidants more effectively than traditional heat treatments. HPP is widely used in the beverage industry to ensure safety and quality while meeting consumer demand for minimally processed, clean-label products.

Understanding Aseptic Processing in Beverages

Aseptic processing in beverages involves sterilizing the product and packaging separately before filling under sterile conditions, preserving flavor and nutrients without the need for preservatives. This method extends shelf life significantly by preventing microbial contamination while maintaining the beverage's original taste and color. Compared to High-Pressure Processing (HPP), aseptic processing is more effective for shelf-stable products requiring longer storage without refrigeration.

Key Differences Between HPP and Aseptic Processing

High-Pressure Processing (HPP) uses extreme pressure to inactivate microbes in beverages without heat, preserving natural flavors and nutrients, whereas Aseptic Processing involves sterilizing both product and packaging separately with heat before filling in a sterile environment. HPP maintains fresh-like taste and higher nutritional quality but has limitations in packaging materials, while Aseptic Processing allows for longer shelf life at room temperature with flexible packaging options. The choice between HPP and Aseptic Processing impacts product quality, shelf life, and packaging design in the beverage industry.

Impact on Nutritional Quality and Flavor

High-Pressure Processing (HPP) preserves the nutritional quality and flavor of beverages by inactivating pathogens without heat, maintaining vitamins, antioxidants, and natural taste profiles. Aseptic Processing, involving high-temperature sterilization, can degrade heat-sensitive nutrients and alter flavor compounds, resulting in reduced freshness perception. HPP offers superior retention of bioactive compounds and natural fruit flavors compared to aseptic methods, making it a preferred choice for premium beverage preservation.

Shelf Life: HPP vs Aseptic Processing

High-Pressure Processing (HPP) extends beverage shelf life by inactivating pathogens and spoilage microorganisms without heat, preserving freshness and nutrients for up to 45 days under refrigeration. Aseptic processing achieves longer shelf stability, often exceeding 6 months at ambient temperatures, through ultra-high temperature sterilization combined with sterile packaging. Shelf life choice depends on product type, distribution conditions, and desired sensory quality in beverages.

Safety and Microbial Inactivation

High-Pressure Processing (HPP) achieves microbial inactivation by applying ultra-high pressure, effectively eliminating pathogens while preserving beverage freshness and nutrients. Aseptic Processing combines thermal sterilization with sterile packaging to ensure safety by destroying microorganisms and spores but may alter flavor and nutrient profiles. Both technologies enhance beverage safety, with HPP preferred for cold-pressed juices and aseptic processing widely used for shelf-stable dairy and juice products.

Cost and Production Efficiency Comparison

High-Pressure Processing (HPP) incurs higher initial equipment costs but offers superior product quality and longer shelf life without preservatives, leading to potential savings in distribution and waste reduction. Aseptic Processing requires less expensive machinery and enables continuous production with faster throughput, making it more cost-effective for large-scale beverage manufacturing. While HPP excels in preserving freshness and nutrient content, aseptic processing is favored for maximizing production efficiency and minimizing per-unit costs.

Sustainability and Environmental Considerations

High-Pressure Processing (HPP) significantly reduces energy consumption compared to Aseptic Processing by eliminating the need for high heat and sterilization chemicals, thereby lowering carbon emissions in beverage production. HPP technology also minimizes water usage and waste generation, promoting a circular economy within sustainable beverage manufacturing. In contrast, Aseptic Processing requires continuous energy input for thermal sterilization and generates more packaging waste, challenging its environmental sustainability.

Choosing the Right Processing Method for Your Beverage Brand

High-Pressure Processing (HPP) offers superior retention of nutrients, flavor, and color in cold-pressed juices and smoothies, making it ideal for premium, fresh-tasting beverages. Aseptic Processing excels in extending shelf life for shelf-stable products like juices and dairy alternatives by sterilizing both product and packaging at high temperatures. Selecting between HPP and aseptic processing depends on product type, desired shelf life, and target market preferences for freshness versus convenience.

High-Pressure Processing (HPP) vs Aseptic Processing Infographic

productdif.com

productdif.com