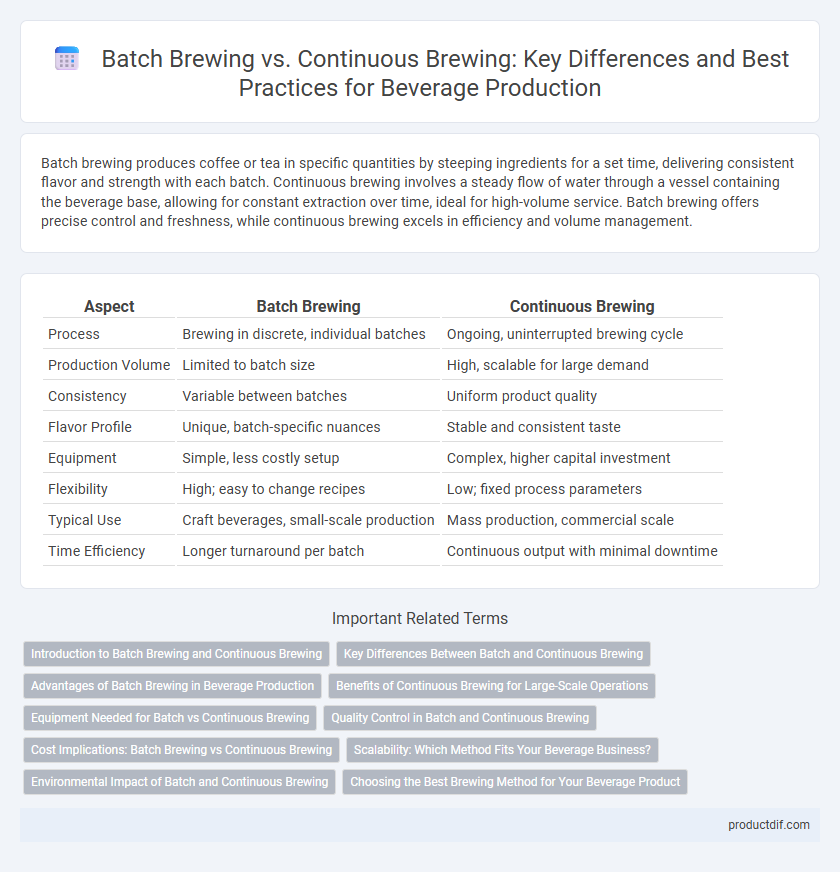

Batch brewing produces coffee or tea in specific quantities by steeping ingredients for a set time, delivering consistent flavor and strength with each batch. Continuous brewing involves a steady flow of water through a vessel containing the beverage base, allowing for constant extraction over time, ideal for high-volume service. Batch brewing offers precise control and freshness, while continuous brewing excels in efficiency and volume management.

Table of Comparison

| Aspect | Batch Brewing | Continuous Brewing |

|---|---|---|

| Process | Brewing in discrete, individual batches | Ongoing, uninterrupted brewing cycle |

| Production Volume | Limited to batch size | High, scalable for large demand |

| Consistency | Variable between batches | Uniform product quality |

| Flavor Profile | Unique, batch-specific nuances | Stable and consistent taste |

| Equipment | Simple, less costly setup | Complex, higher capital investment |

| Flexibility | High; easy to change recipes | Low; fixed process parameters |

| Typical Use | Craft beverages, small-scale production | Mass production, commercial scale |

| Time Efficiency | Longer turnaround per batch | Continuous output with minimal downtime |

Introduction to Batch Brewing and Continuous Brewing

Batch brewing involves making coffee in separate, discrete quantities, allowing control over flavor by adjusting brewing time and temperature for each batch. Continuous brewing, common in commercial settings, extracts coffee steadily as water flows through grounds, producing a constant supply but with less control over variability. Both methods impact taste profiles and operational efficiency in beverage preparation.

Key Differences Between Batch and Continuous Brewing

Batch brewing produces coffee or beer in separate, discrete quantities, allowing for greater control over flavor and ingredient adjustments per batch. Continuous brewing operates with a steady, ongoing process where ingredients are constantly added and extracted, resulting in higher efficiency and consistent flavor profiles. Key differences include production scale, process control, flavor variation, and operational complexity, with batch brewing favoring artisanal quality and continuous brewing suited for mass production.

Advantages of Batch Brewing in Beverage Production

Batch brewing in beverage production offers precise control over flavor profiles and ingredient quality, allowing producers to maintain consistency and tailor each batch to specific taste preferences. This method also facilitates easy experimentation with small volumes, reducing waste and enabling rapid response to market trends. Moreover, batch brewing requires less complex equipment, lowering initial investment and maintenance costs compared to continuous brewing systems.

Benefits of Continuous Brewing for Large-Scale Operations

Continuous brewing offers significant efficiency advantages for large-scale beverage production by enabling uninterrupted fermentation, which reduces downtime and maximizes output. This method ensures consistent flavor profiles and product quality through precise control over fermentation parameters, facilitating scalability and uniformity across large batches. Operational costs decrease due to lower energy consumption and minimized waste, making continuous brewing an economically viable solution for high-volume beverage manufacturers.

Equipment Needed for Batch vs Continuous Brewing

Batch brewing requires discrete equipment such as mash tuns, lauter tuns, and fermentation tanks sized for individual batches, allowing precise control over each brewing cycle. Continuous brewing utilizes specialized, integrated systems like continuous fermenters and steady-state wort mixing vessels that enable constant production flow without interruption. The major difference lies in batch brewing's modular setup versus continuous brewing's complex, automated machinery optimized for large-scale, uninterrupted output.

Quality Control in Batch and Continuous Brewing

Batch brewing allows for precise quality control by monitoring each individual batch for consistency, flavor profile, and potential contamination, making it ideal for craft beverage production. Continuous brewing operates on an ongoing fermentation process, which can result in variable quality due to less frequent sampling and adjustments, but it ensures large-scale volume efficiency. Quality control in continuous brewing relies heavily on automated systems and regular maintenance to minimize deviations and maintain product standards.

Cost Implications: Batch Brewing vs Continuous Brewing

Batch brewing involves brewing set quantities of beverage at a time, resulting in higher labor and energy costs due to frequent cleaning and repeated heating cycles. Continuous brewing utilizes a steady process that reduces labor input and energy consumption by maintaining a constant brewing environment, lowering operational expenses. For large-scale production, continuous brewing offers improved cost efficiency compared to the more resource-intensive batch brewing method.

Scalability: Which Method Fits Your Beverage Business?

Batch brewing offers limited scalability due to its manual, small-scale production process, making it ideal for craft beverages and niche markets. Continuous brewing enables high-volume production with consistent quality, suitable for large-scale beverage businesses aiming to meet growing demand efficiently. Choosing between batch and continuous brewing depends on your business's growth goals, production capacity, and product consistency requirements.

Environmental Impact of Batch and Continuous Brewing

Batch brewing typically generates more waste and consumes higher amounts of water and energy per unit of beverage produced compared to continuous brewing, which optimizes resource use through constant processing. Continuous brewing minimizes environmental footprint by reducing wastewater output and energy spikes associated with repeated heating cycles in batch processes. Implementing continuous brewing systems can lead to significant reductions in greenhouse gas emissions and lower operational costs in beverage production.

Choosing the Best Brewing Method for Your Beverage Product

Batch brewing offers precise control over flavor profiles, making it ideal for small to medium-scale beverage production where quality and consistency are paramount. Continuous brewing excels in large-scale operations, providing efficient production with lower labor costs and faster turnaround times, suitable for high-demand beverages. Evaluating factors like production volume, flavor consistency, and resource availability will guide beverage producers in selecting the optimal brewing method for their product.

Batch Brewing vs Continuous Brewing Infographic

productdif.com

productdif.com