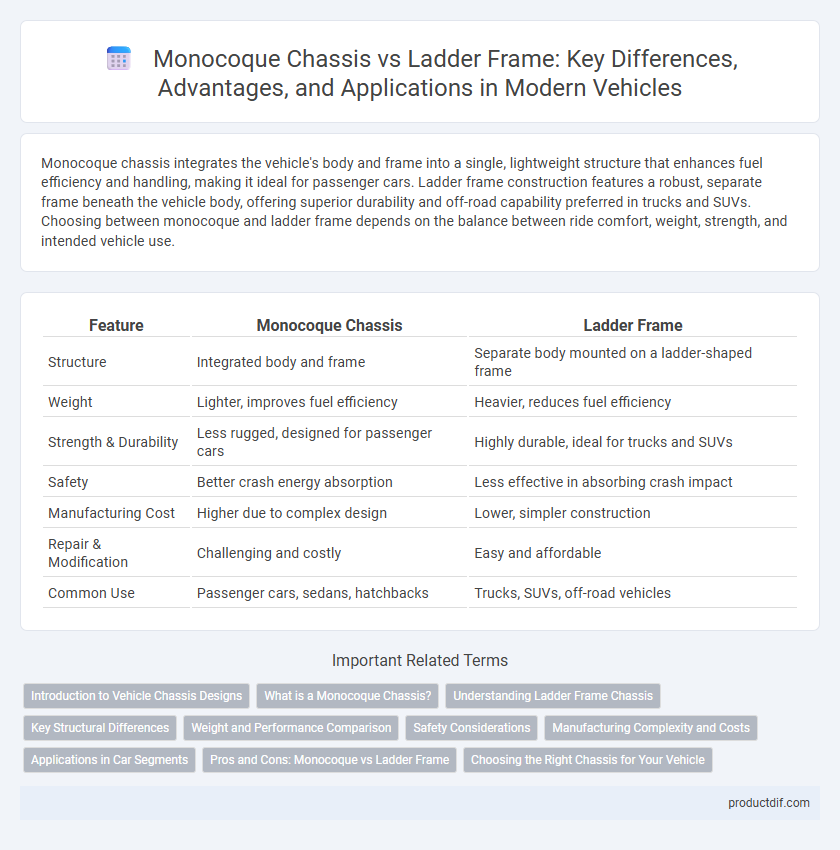

Monocoque chassis integrates the vehicle's body and frame into a single, lightweight structure that enhances fuel efficiency and handling, making it ideal for passenger cars. Ladder frame construction features a robust, separate frame beneath the vehicle body, offering superior durability and off-road capability preferred in trucks and SUVs. Choosing between monocoque and ladder frame depends on the balance between ride comfort, weight, strength, and intended vehicle use.

Table of Comparison

| Feature | Monocoque Chassis | Ladder Frame |

|---|---|---|

| Structure | Integrated body and frame | Separate body mounted on a ladder-shaped frame |

| Weight | Lighter, improves fuel efficiency | Heavier, reduces fuel efficiency |

| Strength & Durability | Less rugged, designed for passenger cars | Highly durable, ideal for trucks and SUVs |

| Safety | Better crash energy absorption | Less effective in absorbing crash impact |

| Manufacturing Cost | Higher due to complex design | Lower, simpler construction |

| Repair & Modification | Challenging and costly | Easy and affordable |

| Common Use | Passenger cars, sedans, hatchbacks | Trucks, SUVs, off-road vehicles |

Introduction to Vehicle Chassis Designs

Monocoque chassis, characterized by a unified body structure, offers enhanced rigidity and reduced weight compared to traditional ladder frames, which consist of two parallel rails joined by crossmembers. The ladder frame chassis provides superior durability and ease of repair, commonly used in trucks and off-road vehicles for its robust load-bearing capacity. Understanding these fundamental differences helps in selecting the optimal chassis design tailored to specific vehicle performance and application requirements.

What is a Monocoque Chassis?

A monocoque chassis is a structural design in vehicles where the body and frame are integrated into a single, unified shell, enhancing rigidity and reducing weight compared to traditional ladder frames. This construction improves crash safety and handling by distributing stress uniformly across the entire body. Commonly used in modern cars and aircraft, monocoque chassis contribute to better fuel efficiency and overall performance through optimized structural integrity.

Understanding Ladder Frame Chassis

A ladder frame chassis consists of two longitudinal beams connected by multiple cross members, providing a robust and durable foundation ideal for heavy-duty vehicles like trucks and SUVs. Its simple, strong design allows for easy mounting of body and drivetrain components, enhancing torsional rigidity and impact resistance on rough terrains. Although heavier than monocoque chassis, the ladder frame excels in off-road performance and repairability, making it a preferred choice for vehicles requiring high load capacity and durability.

Key Structural Differences

Monocoque chassis integrates the body and frame into a single shell, providing superior rigidity and lighter weight compared to ladder frames, which consist of two parallel beams connected by cross members supporting the vehicle body. Ladder frames offer exceptional durability and are better suited for heavy-duty applications due to their robust, separate structure that absorbs impacts independently from the body. The monocoque design enhances fuel efficiency and handling by reducing overall mass, while ladder frames prioritize strength and ease of repair in off-road and commercial vehicles.

Weight and Performance Comparison

Monocoque chassis typically weigh less than ladder frames, contributing to improved fuel efficiency and handling due to a lower center of gravity. Ladder frames, being heavier and more rigid, provide superior durability and off-road performance but may reduce acceleration and agility. The weight advantage of monocoque designs enhances overall vehicle dynamics, making them preferred for passenger cars, while ladder frames remain favored in trucks and SUVs for load-bearing capabilities.

Safety Considerations

Monocoque chassis enhances safety by integrating the body and frame into a single unit, providing superior crash energy absorption and reducing deformation in collisions. Ladder frame structures offer better durability and repairability but may transfer impact forces less effectively, increasing occupant risk. Modern vehicle safety systems increasingly favor monocoque designs for improved crashworthiness and passenger protection.

Manufacturing Complexity and Costs

Monocoque chassis offers lower manufacturing complexity and reduced costs by integrating the body and frame into a single unit, eliminating the need for separate components and welding processes inherent in ladder frame designs. Ladder frames require extensive fabrication and assembly of multiple steel components, increasing labor and material expenses. Advances in monocoque construction techniques, such as hydroforming and adhesive bonding, further streamline production and enhance structural efficiency compared to traditional ladder frame manufacturing.

Applications in Car Segments

Monocoque chassis dominates in passenger cars and SUVs due to its lightweight structure and improved crash safety, enhancing fuel efficiency and handling. Ladder frame remains preferred in heavy-duty trucks and off-road SUVs, offering superior strength and durability for load-bearing and rugged terrain. Sports cars and compact vehicles increasingly adopt monocoque design for stiffness and agility, while commercial vehicles rely on ladder frames for flexibility and easy repair.

Pros and Cons: Monocoque vs Ladder Frame

Monocoque chassis offers superior rigidity and weight savings, enhancing fuel efficiency and handling, but it is generally more expensive and complex to repair after collisions. Ladder frame chassis provides robustness and ease of modification, making it ideal for heavy-duty and off-road vehicles, though it adds extra weight and reduces overall vehicle agility. Choosing between monocoque and ladder frame depends on priorities such as performance, durability, and maintenance needs.

Choosing the Right Chassis for Your Vehicle

Monocoque chassis offer superior rigidity and lighter weight, enhancing fuel efficiency and handling, making them ideal for passenger cars and performance vehicles. Ladder frame chassis provide enhanced durability and ease of repair, preferred for heavy-duty trucks and off-road vehicles due to their ability to withstand rugged conditions. Selecting the right chassis depends on balancing vehicle use, weight requirements, and structural demands to optimize safety, performance, and cost.

Monocoque Chassis vs Ladder Frame Infographic

productdif.com

productdif.com