Push-fit connectors offer quick installation without soldering, making them ideal for DIY plumbing fixture pets and reducing labor time. Sweat fittings require soldering, providing a durable, leak-resistant connection that is preferred for high-pressure applications in plumbing fixtures. Comparing push-fit connectors and sweat fittings reveals a trade-off between ease of use and long-term reliability in pet plumbing setups.

Table of Comparison

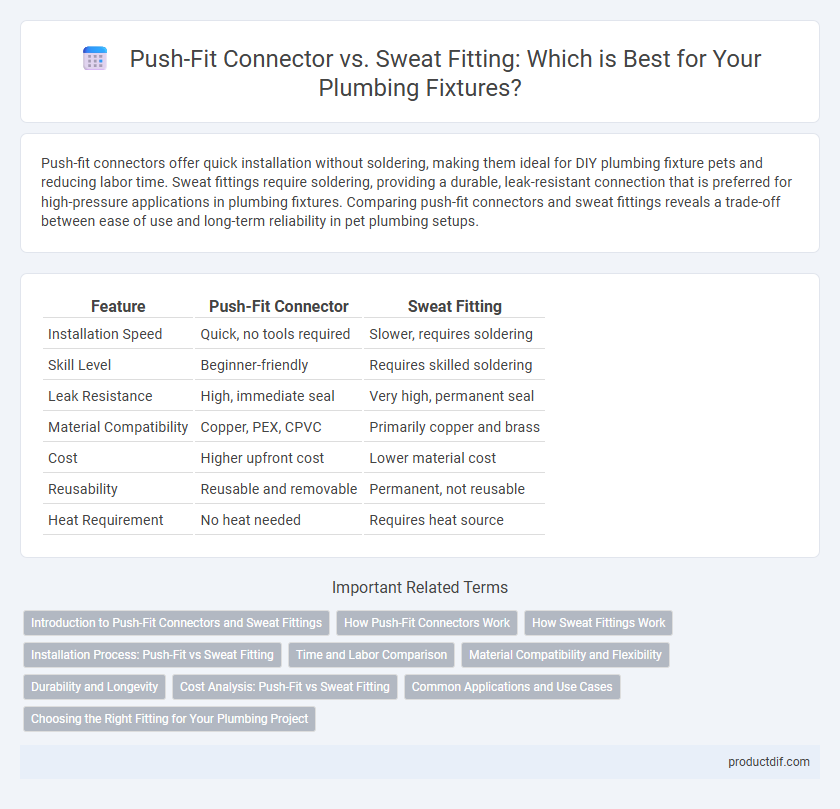

| Feature | Push-Fit Connector | Sweat Fitting |

|---|---|---|

| Installation Speed | Quick, no tools required | Slower, requires soldering |

| Skill Level | Beginner-friendly | Requires skilled soldering |

| Leak Resistance | High, immediate seal | Very high, permanent seal |

| Material Compatibility | Copper, PEX, CPVC | Primarily copper and brass |

| Cost | Higher upfront cost | Lower material cost |

| Reusability | Reusable and removable | Permanent, not reusable |

| Heat Requirement | No heat needed | Requires heat source |

Introduction to Push-Fit Connectors and Sweat Fittings

Push-fit connectors offer a quick, tool-free installation method by simply pushing pipes into the connector for a secure seal, ideal for both copper and plastic pipes. Sweat fittings require soldering, creating a reliable, leak-proof joint through heating and melting of solder, commonly used with copper pipes in traditional plumbing. Both methods provide durable connections, with push-fit favoring speed and ease, while sweat fittings emphasize long-term reliability and strength.

How Push-Fit Connectors Work

Push-fit connectors create a watertight seal by simply pushing the pipe into the fitting, using internal O-rings and metal teeth to grip and secure the pipe without soldering or adhesive. These connectors eliminate the need for heat or special tools, enabling quick installations and easy disassembly for repairs or adjustments. Push-fit technology is compatible with copper, PEX, and CPVC pipes, making it a versatile choice compared to traditional sweat fittings that require soldering for permanent joints.

How Sweat Fittings Work

Sweat fittings, also known as solder fittings, create a leak-proof joint by heating the copper pipe and fitting to melt solder around the connection, which solidifies as it cools for a durable seal. This method requires a torch and flux to clean and prepare the surfaces, ensuring proper adhesion and preventing corrosion. Sweat fittings provide strong, long-lasting connections ideal for high-temperature or high-pressure plumbing systems compared to push-fit connectors.

Installation Process: Push-Fit vs Sweat Fitting

Push-fit connectors simplify the installation process by requiring no soldering, clamps, or glue, allowing for quick and tool-free connections that reduce labor time and errors, especially in tight spaces. Sweat fittings demand precise preparation, including cleaning the pipe and fitting, applying flux, and heating with a torch to solder the joint securely, which ensures a durable and leak-resistant connection but requires skilled labor and safety precautions. Choosing between push-fit and sweat fittings depends on the installer's experience, project timeline, and the need for permanent versus flexible connections.

Time and Labor Comparison

Push-fit connectors significantly reduce installation time by eliminating the need for soldering, making them ideal for quick repairs and complex plumbing layouts. Sweat fittings require more labor-intensive preparation, including cleaning, flux application, and precise soldering, which extends overall project duration. For plumbers prioritizing efficiency, push-fit connectors offer substantial labor savings and faster turnaround times compared to sweat fittings.

Material Compatibility and Flexibility

Push-fit connectors excel in material compatibility by securely joining a wide range of pipes including copper, PEX, CPVC, and PVC without requiring specialized tools or soldering, offering versatility and ease of use. Sweat fittings, predominantly designed for copper pipes, involve soldering to create permanent, leak-proof joints, which limits flexibility but ensures strong, durable connections suitable for high-temperature applications. The choice between push-fit connectors and sweat fittings hinges on project requirements for material compatibility, installation speed, and the need for potentially disassembling connections.

Durability and Longevity

Push-fit connectors offer quick installation but generally have lower durability compared to sweat fittings, which create a permanent, soldered connection resistant to leaks and corrosion. Sweat fittings, made from copper or brass, provide superior longevity by withstanding high temperatures and pressure fluctuations common in plumbing systems. Choosing sweat fittings ensures a more reliable and long-lasting plumbing fixture, especially in demanding environments.

Cost Analysis: Push-Fit vs Sweat Fitting

Push-fit connectors typically cost more per unit than sweat fittings but save money on labor due to faster installation times and no need for specialized tools or soldering skills. Sweat fittings, while cheaper in material cost, require skilled labor and longer installation times, increasing overall project expenses. Evaluating total cost-effectiveness depends on project scale, labor rates, and urgency, with push-fit systems offering higher upfront costs but reduced labor and downtime.

Common Applications and Use Cases

Push-fit connectors excel in residential plumbing for quick repairs and retrofits, enabling tool-free installation on copper, PEX, and CPVC pipes. Sweat fittings are preferred in commercial and high-pressure systems, offering durable, leak-resistant joints through soldering copper pipes. Push-fit connectors suit temporary or emergency fixes, while sweat fittings provide a long-lasting solution ideal for new construction and extensive plumbing installations.

Choosing the Right Fitting for Your Plumbing Project

Push-fit connectors provide a quick and tool-free installation option, ideal for DIY projects and repairs where speed and ease are priorities. Sweat fittings require soldering, offering a secure, leak-proof bond preferred for long-term durability in copper piping systems. Selecting the right fitting depends on factors like pipe material, skill level, and whether the application demands a permanent or temporary connection.

Push-fit connector vs Sweat fitting Infographic

productdif.com

productdif.com