Ball valves provide quick, reliable shutoff with a simple quarter-turn operation, making them ideal for applications requiring frequent on/off control. Gate valves offer precise flow regulation with a rising or non-rising stem design, suitable for full-flow or throttling use but tend to be slower to operate. Choosing between a ball valve and a gate valve depends on the need for speed, sealing reliability, and flow control in plumbing fixture applications involving pets.

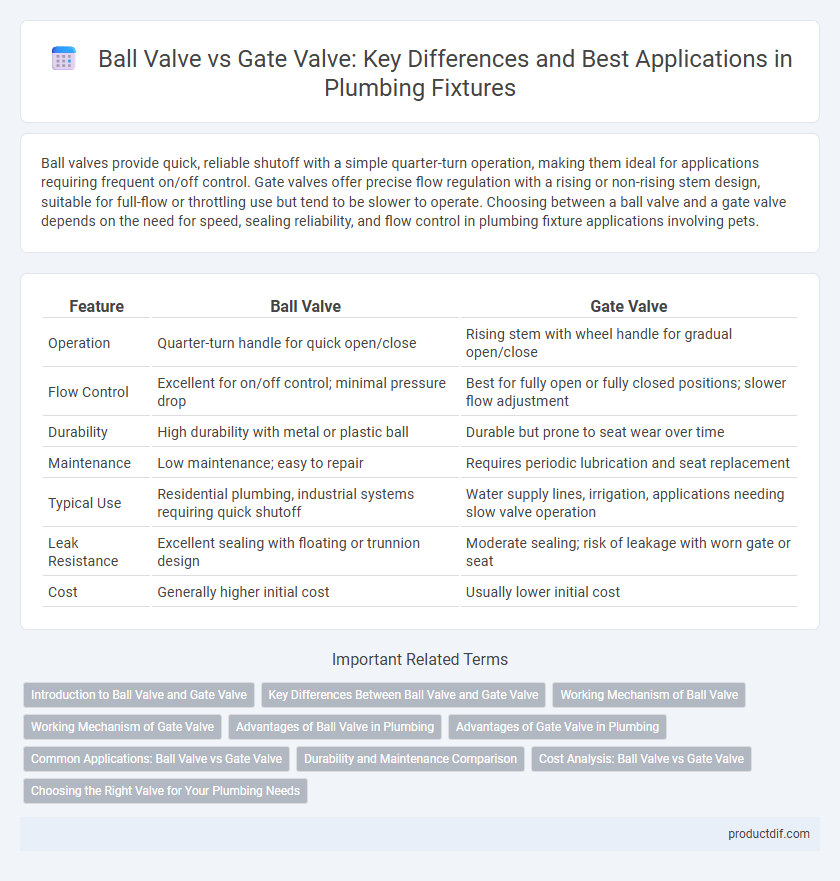

Table of Comparison

| Feature | Ball Valve | Gate Valve |

|---|---|---|

| Operation | Quarter-turn handle for quick open/close | Rising stem with wheel handle for gradual open/close |

| Flow Control | Excellent for on/off control; minimal pressure drop | Best for fully open or fully closed positions; slower flow adjustment |

| Durability | High durability with metal or plastic ball | Durable but prone to seat wear over time |

| Maintenance | Low maintenance; easy to repair | Requires periodic lubrication and seat replacement |

| Typical Use | Residential plumbing, industrial systems requiring quick shutoff | Water supply lines, irrigation, applications needing slow valve operation |

| Leak Resistance | Excellent sealing with floating or trunnion design | Moderate sealing; risk of leakage with worn gate or seat |

| Cost | Generally higher initial cost | Usually lower initial cost |

Introduction to Ball Valve and Gate Valve

Ball valves feature a spherical disc that controls flow through a quarter-turn rotation, providing quick shutoff and reliable sealing in plumbing systems. Gate valves operate with a wedge-shaped gate that moves up and down to regulate flow, ideal for precise throttling in residential and industrial pipelines. Both ball and gate valves are essential for controlling water supply, but their design differences influence application suitability and maintenance requirements.

Key Differences Between Ball Valve and Gate Valve

Ball valves provide quick shutoff with a quarter-turn operation, while gate valves require multiple turns to fully open or close. Ball valves maintain a tight seal and are better suited for applications requiring frequent operation and reliable isolation. Gate valves are ideal for fully open or closed positions, offering minimal pressure drop when fully open but are less effective for throttling or frequent use.

Working Mechanism of Ball Valve

Ball valves operate using a spherical ball with a hole through its center that aligns with the flow when open, allowing unrestricted fluid passage. Turning the valve handle rotates the ball 90 degrees, blocking flow by positioning the solid side perpendicular to the pipe. This quarter-turn mechanism ensures quick operation and reliable sealing, making ball valves ideal for applications requiring tight shut-off and minimal leakage.

Working Mechanism of Gate Valve

Gate valves operate by lifting a flat or wedge-shaped gate out of the fluid path to allow flow, providing minimal pressure drop when fully open. The valve stem moves linearly to raise or lower the gate within the valve body, ensuring a tight seal when closed. This mechanism is ideal for on/off control in plumbing systems due to its robust sealing capability and low resistance in the open position.

Advantages of Ball Valve in Plumbing

Ball valves offer superior sealing capabilities due to their spherical design, ensuring a tight shut-off that prevents leaks in plumbing systems. Their quick quarter-turn operation allows for faster flow control compared to the slower, multi-turn mechanism of gate valves. Ball valves also provide greater durability and reliability under high-pressure and high-temperature conditions, making them ideal for modern plumbing applications.

Advantages of Gate Valve in Plumbing

Gate valves provide a tight seal that effectively prevents water leakage, making them ideal for plumbing systems requiring full shut-off. Their design allows minimal pressure drop and unobstructed flow when fully open, which enhances system efficiency. These valves are durable and capable of handling high pressure and temperature, making them suitable for various residential and commercial plumbing applications.

Common Applications: Ball Valve vs Gate Valve

Ball valves are commonly used in applications requiring quick shut-off and precise flow control, such as in residential plumbing, gas lines, and HVAC systems. Gate valves are preferred in situations where a straight-line flow of fluid and minimum restriction is important, often found in water supply systems, irrigation, and industrial pipelines. Both valves serve critical roles, with ball valves excelling in on/off control and gate valves suited for fully open or closed positions in high-pressure environments.

Durability and Maintenance Comparison

Ball valves offer superior durability due to their simple design and robust sealing mechanism, reducing wear over time compared to gate valves, which have more moving parts prone to corrosion and wear. Maintenance for ball valves is minimal; they rarely require servicing and can function effectively with infrequent lubrication, while gate valves demand regular maintenance to prevent stem and gate corrosion, ensuring smooth operation. Their differences in durability and maintenance make ball valves ideal for high-cycle applications, whereas gate valves suit systems requiring infrequent valve operation.

Cost Analysis: Ball Valve vs Gate Valve

Ball valves typically cost more initially than gate valves due to their complex design and materials used, but they offer lower maintenance expenses and longer service life. Gate valves are generally cheaper upfront but may incur higher repair and replacement costs over time because of their susceptibility to wear and operational issues. Evaluating total cost of ownership shows ball valves provide better economic efficiency in long-term plumbing fixture applications.

Choosing the Right Valve for Your Plumbing Needs

Ball valves provide quick shut-off with a quarter-turn mechanism, making them ideal for applications requiring frequent operation and reliability. Gate valves offer precise flow control with a rising stem design, suitable for systems needing minimal pressure drop and full unobstructed flow. Selecting the right valve depends on factors like flow control requirements, space constraints, and maintenance frequency in your plumbing system.

Ball Valve vs Gate Valve Infographic

productdif.com

productdif.com