Sweat fittings provide a secure, permanent connection through soldering copper pipes, ensuring durability and leak resistance in plumbing fixtures for pets. Push-to-connect fittings offer a faster, tool-free installation ideal for quick repairs or modifications, using a locking mechanism that grips the pipe without soldering. Choosing between sweat and push-to-connect fittings depends on the need for a long-lasting, professional seal versus convenience and ease of use in pet plumbing systems.

Table of Comparison

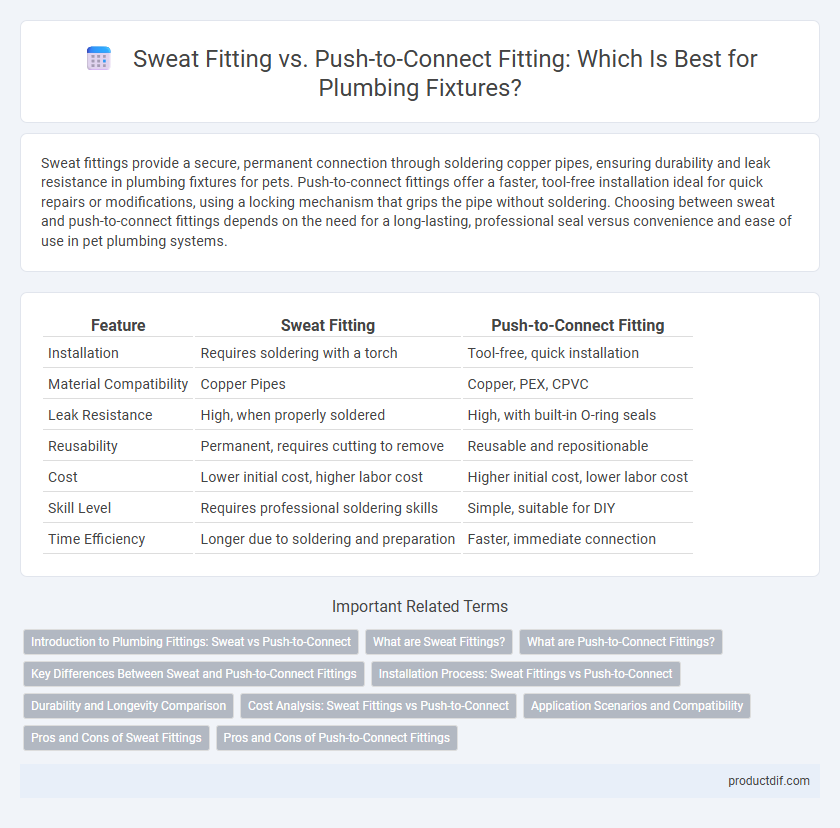

| Feature | Sweat Fitting | Push-to-Connect Fitting |

|---|---|---|

| Installation | Requires soldering with a torch | Tool-free, quick installation |

| Material Compatibility | Copper Pipes | Copper, PEX, CPVC |

| Leak Resistance | High, when properly soldered | High, with built-in O-ring seals |

| Reusability | Permanent, requires cutting to remove | Reusable and repositionable |

| Cost | Lower initial cost, higher labor cost | Higher initial cost, lower labor cost |

| Skill Level | Requires professional soldering skills | Simple, suitable for DIY |

| Time Efficiency | Longer due to soldering and preparation | Faster, immediate connection |

Introduction to Plumbing Fittings: Sweat vs Push-to-Connect

Sweat fittings require soldering copper pipes, creating a durable, leak-resistant joint ideal for long-term plumbing systems, especially in residential and commercial water supply lines. Push-to-connect fittings offer a quick and tool-free installation method, using internal O-rings to seal pipes, making them highly convenient for repairs and tight spaces where soldering is impractical. Both fittings serve vital roles in plumbing, with sweat fittings favored for permanent setups and push-to-connect fittings chosen for efficiency and ease of use.

What are Sweat Fittings?

Sweat fittings are plumbing connectors designed to join copper pipes by soldering, creating a strong, leak-proof seal through the melting of a filler metal. These fittings require precise preparation, including cleaning and applying flux to the pipe and fitting before heating with a torch to melt the solder. Commonly used in residential and commercial water supply systems, sweat fittings provide durable, corrosion-resistant joints ideal for permanent installations.

What are Push-to-Connect Fittings?

Push-to-connect fittings are versatile plumbing connectors designed for rapid, tool-free connections by simply pushing the pipe into the fitting, creating a secure, watertight seal. Commonly made from durable materials such as brass or plastic, these fittings are compatible with copper, PEX, CPVC, and PVC pipes, offering flexibility across various plumbing systems. Their ease of installation and reusability make push-to-connect fittings an efficient choice for both residential and commercial plumbing repairs and new installations.

Key Differences Between Sweat and Push-to-Connect Fittings

Sweat fittings require soldering copper pipes, creating a permanent, leak-resistant connection ideal for high-pressure applications, whereas push-to-connect fittings provide a tool-free, reusable, and quick installation solution compatible with various pipe materials including copper, PEX, and CPVC. Sweat fittings demand skill and heat application, making them less suitable for DIY projects, while push-to-connect fittings offer convenience and flexibility with their gasket-based sealing mechanism. The key differences lie in installation method, permanence, compatibility, and the necessity of specialized tools or soldering skills.

Installation Process: Sweat Fittings vs Push-to-Connect

Sweat fittings require soldering copper pipes with flux and a torch, demanding skill and time to ensure a leak-free connection. Push-to-connect fittings offer a faster and easier installation by simply pushing pipes into the fitting for an instant, secure seal, eliminating the need for soldering or special tools. While sweat fittings provide a permanent bond, push-to-connect fittings are ideal for quick repairs and DIY projects due to their reversible and user-friendly installation process.

Durability and Longevity Comparison

Sweat fittings, made from copper and soldered joints, offer superior durability and longevity due to their resistance to corrosion and ability to withstand high temperatures and pressures over time. Push-to-connect fittings, while convenient and faster to install, may have limited lifespan in harsh environments as the internal O-rings can degrade, potentially leading to leaks. For long-term plumbing solutions, sweat fittings are generally preferred for their robust performance and lasting reliability.

Cost Analysis: Sweat Fittings vs Push-to-Connect

Sweat fittings typically require copper pipes and soldering equipment, making initial costs lower for experienced plumbers but higher for DIY due to tool and skill needs. Push-to-connect fittings, while more expensive per unit, reduce labor time and can lower overall installation expenses, especially in complex or time-sensitive projects. Evaluating the balance between material costs and labor efficiency is crucial for cost-effective plumbing fixture installations.

Application Scenarios and Compatibility

Sweat fittings are ideal for permanent plumbing connections in copper piping systems, ensuring leak-proof joints through soldering, making them suitable for residential and commercial water supply lines. Push-to-connect fittings offer superior versatility and ease of installation, compatible with various pipe materials like copper, PEX, and CPVC, making them perfect for quick repairs, remodeling, and tight spaces. While sweat fittings excel in durability and pressure resistance, push-to-connect fittings provide convenience and flexibility in applications requiring frequent disassembly.

Pros and Cons of Sweat Fittings

Sweat fittings offer a reliable, permanent connection ideal for copper piping in plumbing systems, with excellent durability and leak resistance when properly soldered. They require a skilled application process involving heat and solder, making installation time-consuming and less suitable for quick repairs or DIY projects. However, their strong, corrosion-resistant joints provide long-term stability, beneficial for systems exposed to high pressure or temperature variations.

Pros and Cons of Push-to-Connect Fittings

Push-to-connect fittings offer easy and quick installation without the need for soldering, making them ideal for DIY projects and repairs. Their reliable, leak-proof seals work well with various pipe materials such as copper, PEX, and CPVC, reducing the risk of future leaks. However, push-to-connect fittings are generally more expensive than sweat fittings and may not be suitable for high-temperature or high-pressure plumbing systems.

sweat fitting vs push-to-connect fitting Infographic

productdif.com

productdif.com