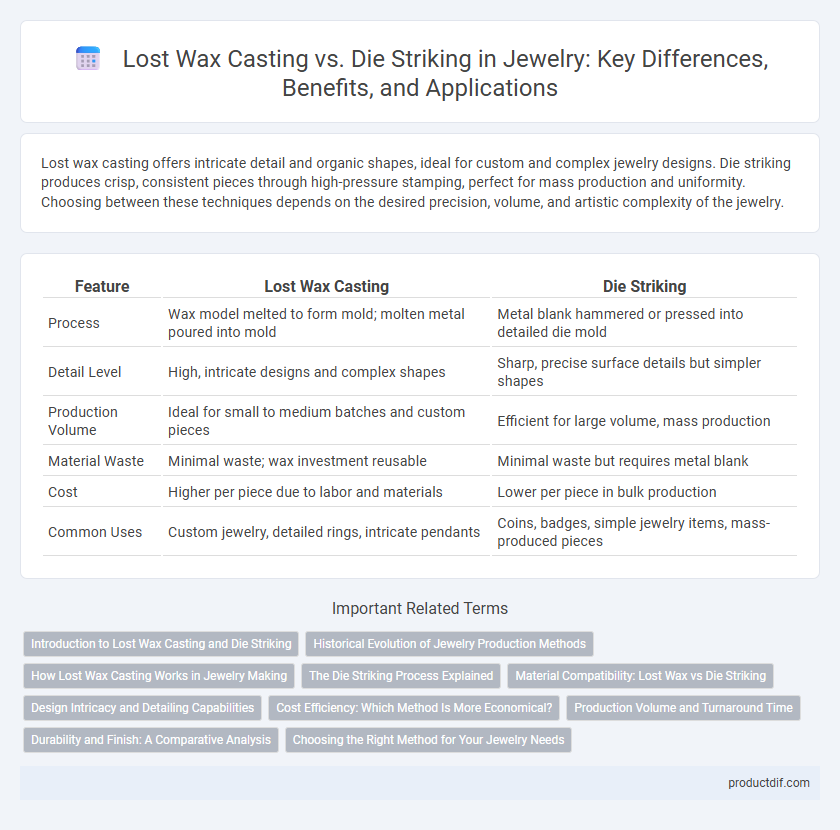

Lost wax casting offers intricate detail and organic shapes, ideal for custom and complex jewelry designs. Die striking produces crisp, consistent pieces through high-pressure stamping, perfect for mass production and uniformity. Choosing between these techniques depends on the desired precision, volume, and artistic complexity of the jewelry.

Table of Comparison

| Feature | Lost Wax Casting | Die Striking |

|---|---|---|

| Process | Wax model melted to form mold; molten metal poured into mold | Metal blank hammered or pressed into detailed die mold |

| Detail Level | High, intricate designs and complex shapes | Sharp, precise surface details but simpler shapes |

| Production Volume | Ideal for small to medium batches and custom pieces | Efficient for large volume, mass production |

| Material Waste | Minimal waste; wax investment reusable | Minimal waste but requires metal blank |

| Cost | Higher per piece due to labor and materials | Lower per piece in bulk production |

| Common Uses | Custom jewelry, detailed rings, intricate pendants | Coins, badges, simple jewelry items, mass-produced pieces |

Introduction to Lost Wax Casting and Die Striking

Lost wax casting is a traditional jewelry manufacturing technique that involves creating a detailed wax model, which is then encased in a mold, melted away, and replaced with molten metal to form intricate designs. Die striking uses high pressure to stamp precious metal sheets into predefined shapes, offering precision and consistency for mass production. Both methods are fundamental in jewelry making, with lost wax casting favored for complex, custom pieces and die striking suited for uniform, high-volume items.

Historical Evolution of Jewelry Production Methods

Lost wax casting, dating back over 5,000 years, revolutionized jewelry production by enabling intricate, detailed designs through molten metal poured into wax molds. Die striking, developed during the industrial revolution, introduced precision and efficiency with high-pressure stamping of metal blanks using engraved dies, ideal for mass production. These contrasting techniques mark significant advancements in jewelry craftsmanship, shifting from handcrafted uniqueness to standardized, high-volume manufacturing.

How Lost Wax Casting Works in Jewelry Making

Lost wax casting in jewelry making involves creating a detailed wax model of the desired piece, which is then encased in a heat-resistant mold. Once the mold hardens, the wax is melted away, leaving a precise cavity into which molten metal is poured to form the jewelry. This method allows for intricate designs with fine details, offering greater flexibility than die striking.

The Die Striking Process Explained

The die striking process in jewelry manufacturing involves using high-pressure presses to stamp designs from metal sheets, producing precise and detailed pieces with consistent quality. This method is ideal for creating sharp-edged patterns, logos, and coin-like jewelry items, offering faster production speeds compared to lost wax casting. Die striking requires durable steel dies and is most cost-effective for large-scale runs, ensuring uniformity and reducing material waste.

Material Compatibility: Lost Wax vs Die Striking

Lost wax casting excels in complex designs and is compatible with a wide range of metals including gold, silver, platinum, and bronze, allowing for intricate detailing that die striking cannot achieve. Die striking is ideal for high-volume production but works best with softer metals like silver and gold alloys due to the high pressure involved, which can limit the use of harder metals. Choosing between lost wax casting and die striking depends on the metal's hardness, the design complexity, and the desired finish quality.

Design Intricacy and Detailing Capabilities

Lost wax casting enables the creation of highly intricate and detailed jewelry designs by allowing molten metal to flow into every fine crevice of the wax mold, capturing complex textures and delicate patterns with exceptional precision. Die striking offers a more uniform finish with sharp, consistent lines but is generally better suited for simpler, less elaborate designs due to limitations in mold depth and detail reproduction. Choosing between the two methods depends on the desired level of design intricacy and the specific detailing requirements of the jewelry piece.

Cost Efficiency: Which Method Is More Economical?

Lost wax casting generally incurs higher initial costs due to the detailed mold creation and wax model process, making it less economical for large-scale production. Die striking uses pre-made steel dies, offering faster turnaround and lower per-piece costs, which enhances cost efficiency for high-volume jewelry manufacturing. For small batches or intricate designs, lost wax casting justifies its expense with superior detail, but die striking remains the more economical choice overall.

Production Volume and Turnaround Time

Lost wax casting enables the creation of intricate jewelry designs with shorter production runs, offering faster turnaround times ideal for custom or limited-edition pieces. Die striking excels in high-volume production, delivering consistent quality and rapid output suitable for large-scale jewelry manufacturing. Choosing between these methods depends on the desired quantity and speed, with lost wax casting favoring bespoke craftsmanship and die striking meeting mass production demands.

Durability and Finish: A Comparative Analysis

Lost wax casting produces intricate jewelry pieces with a high level of detail and a smooth finish, ideal for complex designs, while die striking offers superior durability due to the metal's compressed grain structure, enhancing strength and wear resistance. The finish achieved through lost wax casting may require additional polishing to achieve the same crispness as die struck items, which naturally have a cleaner, sharper appearance. Jewelry made via die striking typically withstands daily wear better, making it preferable for rings and bracelets, whereas lost wax casting suits ornamental pieces where fine detail is paramount.

Choosing the Right Method for Your Jewelry Needs

Lost wax casting offers intricate detail and customization, ideal for unique or complex jewelry designs, while die striking excels in producing high volumes of consistent, sharp-edged pieces. Selecting the right method depends on factors such as design complexity, production quantity, and budget constraints. Craft jewelers and manufacturers weigh these considerations to align their process with the desired craftsmanship and efficiency.

Lost Wax Casting vs Die Striking Infographic

productdif.com

productdif.com