Traditional craftsmanship in jewelry offers unparalleled attention to detail and timeless artistry, creating pieces with unique character and sentimental value. 3D printing revolutionizes the industry by enabling rapid prototyping, intricate designs, and increased accessibility to custom jewelry. Combining these techniques allows jewelers to preserve heritage while embracing innovation for exceptional and personalized creations.

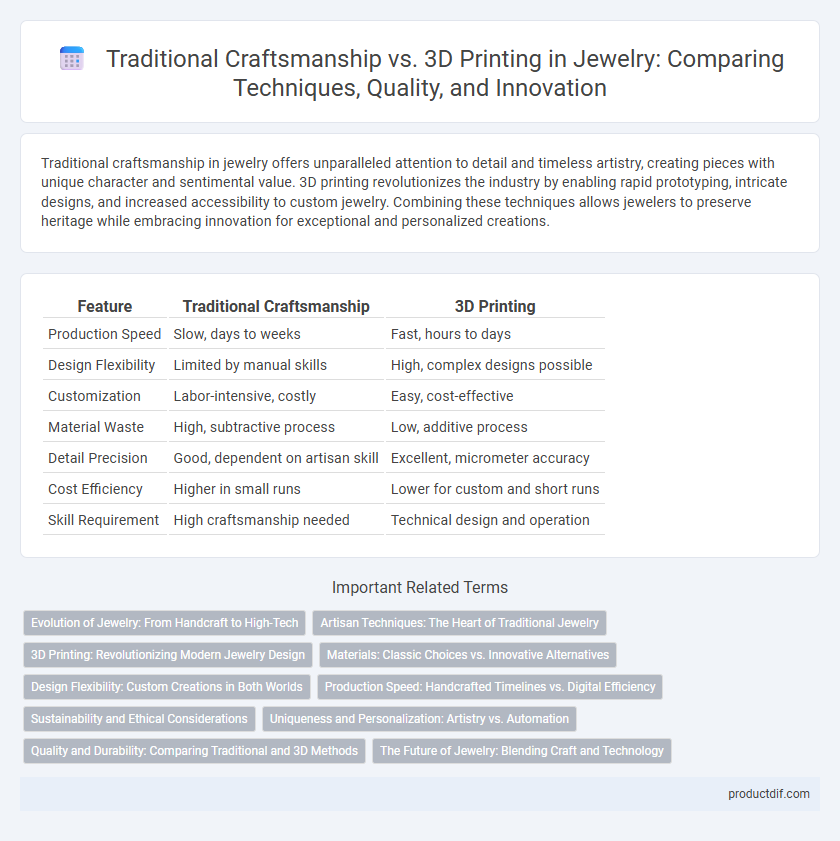

Table of Comparison

| Feature | Traditional Craftsmanship | 3D Printing |

|---|---|---|

| Production Speed | Slow, days to weeks | Fast, hours to days |

| Design Flexibility | Limited by manual skills | High, complex designs possible |

| Customization | Labor-intensive, costly | Easy, cost-effective |

| Material Waste | High, subtractive process | Low, additive process |

| Detail Precision | Good, dependent on artisan skill | Excellent, micrometer accuracy |

| Cost Efficiency | Higher in small runs | Lower for custom and short runs |

| Skill Requirement | High craftsmanship needed | Technical design and operation |

Evolution of Jewelry: From Handcraft to High-Tech

The evolution of jewelry showcases a dynamic shift from traditional craftsmanship, characterized by meticulous hand carving and metalworking, to advanced 3D printing technologies that enable precise, customizable designs with reduced production time. Handcrafted jewelry reflects cultural heritage and artisanal skill, while 3D printing leverages digital modeling and additive manufacturing to push creative boundaries and scale production efficiently. This fusion of ancient techniques and high-tech innovation drives a new era in jewelry design, balancing artistry with technological advancement.

Artisan Techniques: The Heart of Traditional Jewelry

Artisan techniques in traditional jewelry involve meticulous handcrafting methods such as engraving, filigree work, and stone setting, preserving cultural heritage and individual artistry. These time-honored skills result in unique, bespoke pieces that reflect the jeweler's expertise and creativity. Unlike 3D printing, traditional craftsmanship emphasizes tactile precision and the emotional value embedded in handmade designs.

3D Printing: Revolutionizing Modern Jewelry Design

3D printing revolutionizes modern jewelry design by enabling intricate and customizable pieces that traditional craftsmanship cannot easily achieve. This technology allows rapid prototyping and precise detailing, significantly reducing production time and material waste. Designers leverage 3D printing to push creative boundaries, offering personalized jewelry with complex geometries that enhance both aesthetics and functionality.

Materials: Classic Choices vs. Innovative Alternatives

Traditional craftsmanship in jewelry typically utilizes classic materials such as gold, silver, and precious gemstones, prized for their timeless beauty and durability. In contrast, 3D printing introduces innovative alternatives including resin composites, stainless steel alloys, and bioplastics, enabling complex designs and lightweight structures. Both approaches offer unique material benefits, with traditional methods emphasizing authenticity and 3D printing pushing boundaries of customization and material efficiency.

Design Flexibility: Custom Creations in Both Worlds

Traditional craftsmanship offers unparalleled artistry and intricate detailing through skilled handwork, enabling unique custom jewelry designs with personal touches impossible to replicate by machines. 3D printing technology provides exceptional design flexibility by allowing rapid prototyping and precise customization, facilitating complex geometries and personalized creations that streamline production timelines. Both methods empower jewelers to deliver bespoke pieces, blending time-honored techniques with digital innovation for diverse custom jewelry options.

Production Speed: Handcrafted Timelines vs. Digital Efficiency

Traditional craftsmanship in jewelry involves meticulous handwork that can take weeks to complete intricate designs, ensuring unique and detailed artistry. In contrast, 3D printing accelerates production speed by digitally replicating complex structures within hours, enabling rapid prototyping and consistent mass production. This digital efficiency reduces timelines significantly while maintaining precision, transforming how jewelry pieces are fabricated and delivered.

Sustainability and Ethical Considerations

Traditional craftsmanship in jewelry emphasizes sustainable sourcing of materials and supports local artisans, reducing environmental impact through minimal waste and energy consumption. 3D printing offers precise material usage and the potential for recycled or bio-based filaments, lowering resource depletion but raises concerns about electronic waste and energy-intensive production processes. Ethical considerations in both methods revolve around responsible sourcing, fair labor practices, and minimizing carbon footprints to promote sustainable luxury in the jewelry industry.

Uniqueness and Personalization: Artistry vs. Automation

Traditional craftsmanship in jewelry offers unparalleled uniqueness through hand-carved details and bespoke design tailored to individual preferences, reflecting the artisan's skill and creativity. In contrast, 3D printing enables precise personalization by automating complex designs and rapidly producing customized pieces with consistent quality. The blend of artistry with automation balances exclusive craftsmanship with scalable, intricate personalization for modern jewelry collections.

Quality and Durability: Comparing Traditional and 3D Methods

Traditional jewelry craftsmanship often yields pieces with superior quality and durability due to meticulous handwork and time-tested techniques. 3D printing enables intricate designs and rapid production but may compromise on long-term durability because of material limitations like resin brittleness. High-quality metals used in traditional methods generally outperform most 3D-printed materials in wear resistance and structural integrity.

The Future of Jewelry: Blending Craft and Technology

The future of jewelry combines traditional craftsmanship with 3D printing technology, enabling intricate designs that were previously impossible to achieve by hand. Artisans use 3D printing to prototype and produce detailed components quickly, while preserving the artisanal touch through hand finishing and customization. This hybrid approach enhances creativity, efficiency, and sustainability, setting a new standard for modern jewelry design and production.

Traditional craftsmanship vs 3D printing Infographic

productdif.com

productdif.com