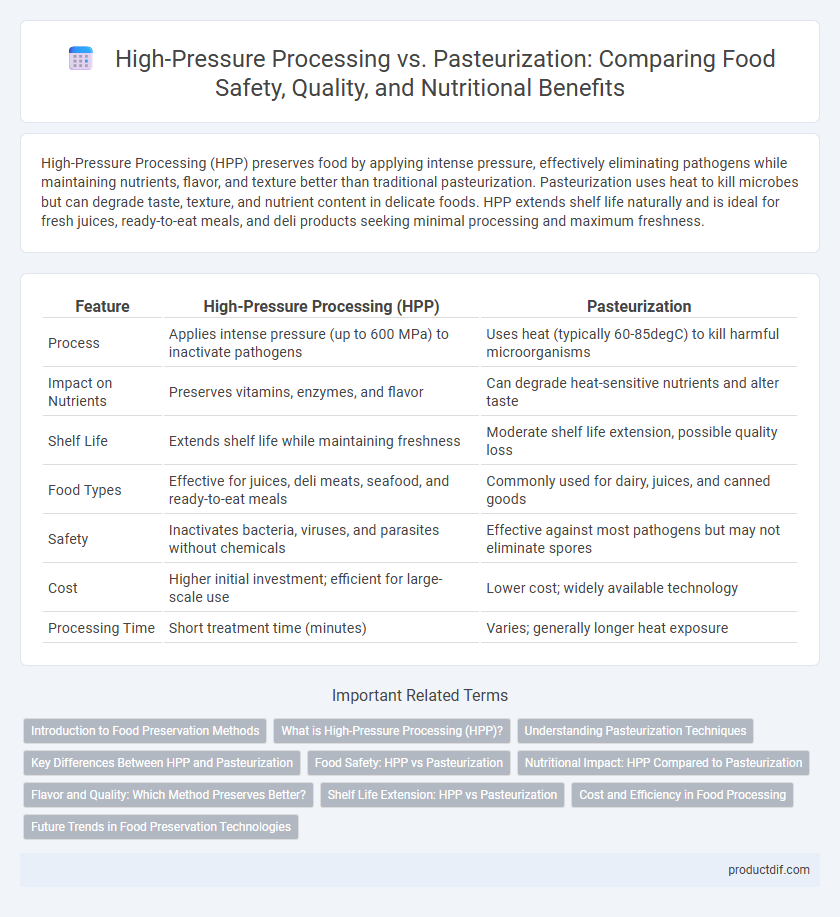

High-Pressure Processing (HPP) preserves food by applying intense pressure, effectively eliminating pathogens while maintaining nutrients, flavor, and texture better than traditional pasteurization. Pasteurization uses heat to kill microbes but can degrade taste, texture, and nutrient content in delicate foods. HPP extends shelf life naturally and is ideal for fresh juices, ready-to-eat meals, and deli products seeking minimal processing and maximum freshness.

Table of Comparison

| Feature | High-Pressure Processing (HPP) | Pasteurization |

|---|---|---|

| Process | Applies intense pressure (up to 600 MPa) to inactivate pathogens | Uses heat (typically 60-85degC) to kill harmful microorganisms |

| Impact on Nutrients | Preserves vitamins, enzymes, and flavor | Can degrade heat-sensitive nutrients and alter taste |

| Shelf Life | Extends shelf life while maintaining freshness | Moderate shelf life extension, possible quality loss |

| Food Types | Effective for juices, deli meats, seafood, and ready-to-eat meals | Commonly used for dairy, juices, and canned goods |

| Safety | Inactivates bacteria, viruses, and parasites without chemicals | Effective against most pathogens but may not eliminate spores |

| Cost | Higher initial investment; efficient for large-scale use | Lower cost; widely available technology |

| Processing Time | Short treatment time (minutes) | Varies; generally longer heat exposure |

Introduction to Food Preservation Methods

High-Pressure Processing (HPP) and pasteurization are advanced food preservation methods that extend shelf life while maintaining nutritional quality. HPP uses extreme pressure to inactivate pathogens and spoilage organisms without heat, preserving flavors and nutrients more effectively than thermal pasteurization. Pasteurization applies controlled heat to eliminate harmful microbes, ensuring food safety but sometimes compromising taste and vitamin content.

What is High-Pressure Processing (HPP)?

High-Pressure Processing (HPP) is a non-thermal food preservation method that uses extremely high pressure, typically between 400 and 600 MPa, to inactivate pathogens and extend shelf life while preserving the food's sensory and nutritional qualities. Unlike traditional pasteurization, HPP does not rely on heat, which prevents nutrient degradation and maintains the fresh taste and texture of products such as juices, meats, and ready-to-eat meals. The process effectively kills harmful bacteria like Listeria and Salmonella without the use of preservatives, making it a preferred technology in clean-label food production.

Understanding Pasteurization Techniques

Pasteurization techniques involve heating food to specific temperatures to eliminate harmful microorganisms while preserving nutritional quality, with common methods including batch pasteurization and continuous flow pasteurization. Batch pasteurization heats the product at 63degC for 30 minutes, primarily used for dairy products, whereas continuous flow pasteurization rapidly heats liquids to 72degC for 15 seconds, ideal for juices and milk. Understanding these methods highlights their effectiveness in ensuring food safety without compromising taste or texture compared to alternative preservation methods like High-Pressure Processing.

Key Differences Between HPP and Pasteurization

High-Pressure Processing (HPP) preserves food by applying intense pressure up to 600 MPa, effectively inactivating pathogens without heat, which maintains nutrients and flavors better than Pasteurization's thermal treatment. Pasteurization relies on elevated temperatures, typically between 60-85degC, to destroy microbes but can cause nutrient degradation and alter taste and texture. Unlike HPP's uniform pressure application, Pasteurization's heat can unevenly affect food consistency and shelf life.

Food Safety: HPP vs Pasteurization

High-Pressure Processing (HPP) achieves food safety by applying intense pressure, effectively inactivating pathogens and preserving nutrients without heat, unlike traditional pasteurization which relies on high temperatures. HPP extends shelf life while maintaining the sensory and nutritional quality of foods, offering a non-thermal alternative to reduce microbial load. Pasteurization remains effective for certain products but can cause nutrient degradation and flavor alterations absent in HPP-treated items.

Nutritional Impact: HPP Compared to Pasteurization

High-Pressure Processing (HPP) preserves more vitamins and antioxidants in food compared to traditional pasteurization, as it uses cold water pressure rather than heat, minimizing nutrient degradation. Studies show that HPP maintains higher levels of vitamin C, folate, and phenolic compounds, which are often reduced during pasteurization due to thermal exposure. This nutrient retention makes HPP a preferred method for preserving the nutritional quality of fresh juices, dairy products, and ready-to-eat meals.

Flavor and Quality: Which Method Preserves Better?

High-Pressure Processing (HPP) preserves flavor and quality more effectively than traditional pasteurization by inactivating pathogens without heat, maintaining the fresh taste and nutritional profile of foods and beverages. Pasteurization uses high temperatures that can alter flavor, texture, and nutrient levels, often resulting in a cooked or processed taste. Studies show HPP-treated products retain vibrant colors, natural aromas, and a superior, fresh-like texture compared to pasteurized counterparts.

Shelf Life Extension: HPP vs Pasteurization

High-Pressure Processing (HPP) extends the shelf life of perishable foods by inactivating spoilage microorganisms without the use of heat, preserving sensory and nutritional quality longer than traditional pasteurization. Pasteurization relies on thermal treatment to eliminate pathogens but often results in shorter shelf life due to enzyme-driven degradation and nutrient loss. Comparative studies show HPP can increase shelf life by 2 to 5 times compared to pasteurized products, making it a preferred choice for fresh juices, ready-to-eat meals, and deli meats.

Cost and Efficiency in Food Processing

High-Pressure Processing (HPP) incurs higher initial equipment costs compared to traditional pasteurization but offers greater efficiency through shorter processing times and reduced thermal damage to products. Pasteurization systems generally require lower capital investment and energy consumption, making them more cost-effective for high-volume, heat-tolerant foods. HPP's ability to preserve sensory and nutritional qualities often justifies its expense for premium or minimally processed food markets seeking extended shelf life.

Future Trends in Food Preservation Technologies

High-pressure processing (HPP) and pasteurization represent key food preservation methods with evolving technologies driving future trends toward minimally processed, nutrient-rich products. Innovations in HPP emphasize cold, non-thermal treatment that better retains flavor, texture, and nutritional value compared to traditional heat-based pasteurization. Emerging hybrid techniques integrating HPP with pulsed electric fields or UV light aim to enhance microbial inactivation while extending shelf life and meeting consumer demand for clean-label foods.

High-Pressure Processing vs Pasteurization Infographic

productdif.com

productdif.com