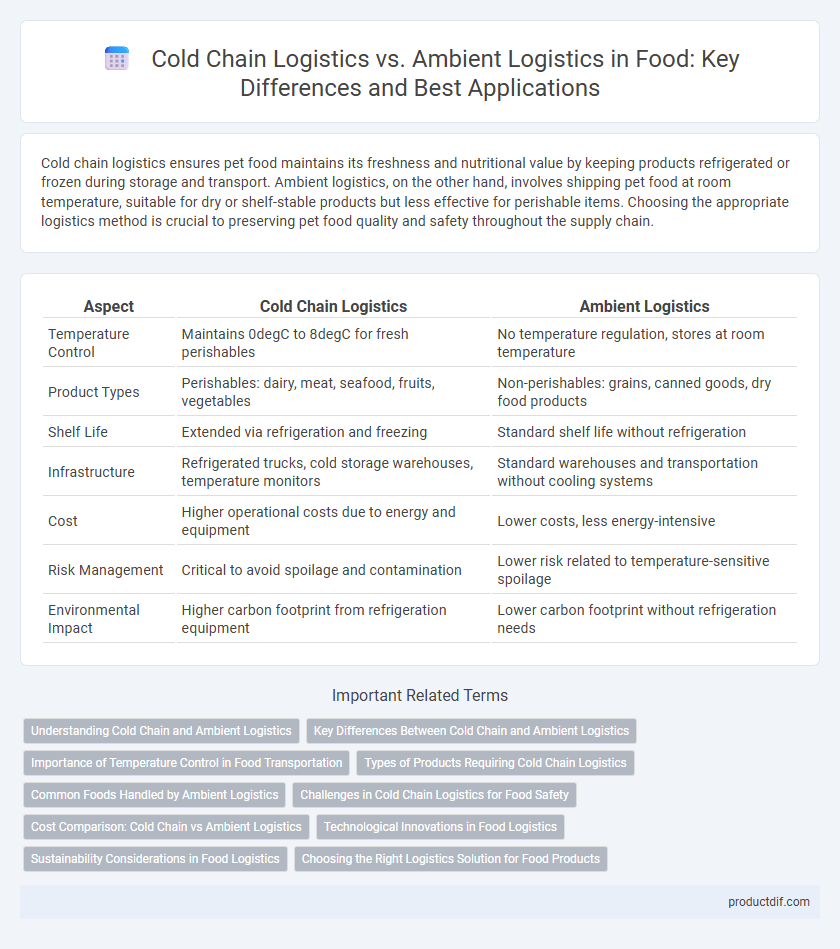

Cold chain logistics ensures pet food maintains its freshness and nutritional value by keeping products refrigerated or frozen during storage and transport. Ambient logistics, on the other hand, involves shipping pet food at room temperature, suitable for dry or shelf-stable products but less effective for perishable items. Choosing the appropriate logistics method is crucial to preserving pet food quality and safety throughout the supply chain.

Table of Comparison

| Aspect | Cold Chain Logistics | Ambient Logistics |

|---|---|---|

| Temperature Control | Maintains 0degC to 8degC for fresh perishables | No temperature regulation, stores at room temperature |

| Product Types | Perishables: dairy, meat, seafood, fruits, vegetables | Non-perishables: grains, canned goods, dry food products |

| Shelf Life | Extended via refrigeration and freezing | Standard shelf life without refrigeration |

| Infrastructure | Refrigerated trucks, cold storage warehouses, temperature monitors | Standard warehouses and transportation without cooling systems |

| Cost | Higher operational costs due to energy and equipment | Lower costs, less energy-intensive |

| Risk Management | Critical to avoid spoilage and contamination | Lower risk related to temperature-sensitive spoilage |

| Environmental Impact | Higher carbon footprint from refrigeration equipment | Lower carbon footprint without refrigeration needs |

Understanding Cold Chain and Ambient Logistics

Cold chain logistics ensures the transportation and storage of perishable food products at controlled temperatures, preserving freshness and preventing spoilage. Ambient logistics handles food items that are shelf-stable at room temperature, reducing the need for specialized refrigeration equipment. Efficient management of both systems is crucial for maintaining food safety, quality, and extending product shelf life.

Key Differences Between Cold Chain and Ambient Logistics

Cold Chain Logistics involves temperature-controlled environments to preserve perishable food items such as dairy, meat, and seafood, ensuring freshness and safety from production to consumption. Ambient Logistics manages non-perishable goods that can be stored and transported at room temperature without risking spoilage. Key differences include temperature control requirements, packaging materials, and monitoring systems that are critical in cold chain but minimal or absent in ambient logistics.

Importance of Temperature Control in Food Transportation

Temperature control in food transportation is critical to maintaining food safety, quality, and nutritional value by preventing microbial growth and spoilage. Cold chain logistics ensures perishable products like dairy, seafood, and fresh produce remain within strict temperature ranges from origin to destination. Ambient logistics, while cost-effective for non-perishable items, lacks precise temperature regulation, increasing risk for temperature-sensitive foods.

Types of Products Requiring Cold Chain Logistics

Perishable food items such as seafood, dairy products, fresh fruits, vegetables, and pharmaceuticals require cold chain logistics to maintain optimal temperature and prevent spoilage. Products like frozen meats, ice cream, and vaccines rely on temperature-controlled environments throughout transportation and storage to ensure safety and quality. In contrast, ambient logistics typically handle non-perishable goods that do not require temperature regulation.

Common Foods Handled by Ambient Logistics

Ambient logistics primarily handle common shelf-stable foods such as canned goods, dry pasta, grains, nuts, and snacks that do not require refrigeration or freezing. These foods benefit from ambient temperature storage and transport, reducing costs and complexity compared to cold chain logistics needed for perishable items like dairy, meat, and fresh produce. Efficient ambient logistics ensure the timely delivery and extended shelf life of these stable food products in retail and distribution networks.

Challenges in Cold Chain Logistics for Food Safety

Cold chain logistics for food safety faces significant challenges such as maintaining consistent temperature control from production to delivery, preventing microbial growth and spoilage. Equipment failures or human errors during handling can lead to temperature excursions that compromise food quality and safety. Regulatory compliance and high operational costs further complicate the effective management of cold chain systems in the food industry.

Cost Comparison: Cold Chain vs Ambient Logistics

Cold chain logistics incur higher operational costs due to refrigeration, temperature monitoring, and specialized packaging needed to maintain product quality. Ambient logistics, optimized for non-perishable goods, significantly reduce expenses by eliminating refrigeration and minimizing energy consumption. When balancing cost-efficiency with product sensitivity, ambient logistics offer lower costs, while cold chain logistics justify higher investments through enhanced preservation of perishables.

Technological Innovations in Food Logistics

Cold chain logistics leverages IoT-enabled temperature sensors and blockchain for real-time monitoring and traceability, ensuring perishable food freshness and safety. Ambient logistics integrates AI-driven predictive analytics and automated warehouse systems to optimize inventory management and reduce spoilage in non-refrigerated food transport. Emerging technologies like advanced refrigeration units and smart packaging are transforming both cold and ambient supply chains by enhancing efficiency and minimizing food waste.

Sustainability Considerations in Food Logistics

Cold chain logistics in food transport ensures temperature-controlled environments, significantly reducing spoilage and food waste but consumes higher energy compared to ambient logistics, which operates at uncontrolled temperatures with lower energy use. Sustainable food logistics increasingly emphasize renewable energy sources and energy-efficient refrigeration technologies in cold chains to mitigate environmental impact. Optimizing routes and improving insulation materials in both cold and ambient logistics further enhance sustainability by reducing carbon emissions and preserving food quality.

Choosing the Right Logistics Solution for Food Products

Cold chain logistics ensures temperature-controlled transportation essential for perishable food items like dairy, seafood, and fresh produce, preserving quality and preventing spoilage. Ambient logistics suits non-perishable goods such as canned foods, grains, and snacks, offering cost-effective storage without refrigeration. Selecting the right logistics solution depends on the product's shelf life, temperature sensitivity, and supply chain complexity to maintain food safety and optimize distribution efficiency.

Cold Chain Logistics vs Ambient Logistics Infographic

productdif.com

productdif.com