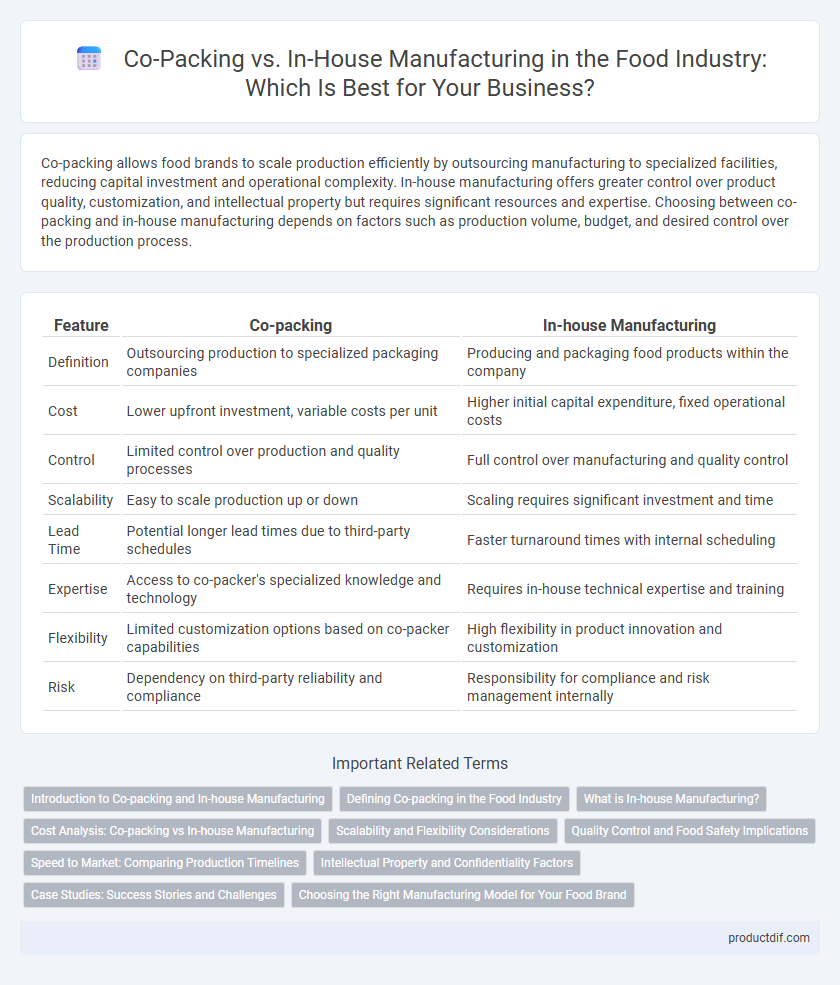

Co-packing allows food brands to scale production efficiently by outsourcing manufacturing to specialized facilities, reducing capital investment and operational complexity. In-house manufacturing offers greater control over product quality, customization, and intellectual property but requires significant resources and expertise. Choosing between co-packing and in-house manufacturing depends on factors such as production volume, budget, and desired control over the production process.

Table of Comparison

| Feature | Co-packing | In-house Manufacturing |

|---|---|---|

| Definition | Outsourcing production to specialized packaging companies | Producing and packaging food products within the company |

| Cost | Lower upfront investment, variable costs per unit | Higher initial capital expenditure, fixed operational costs |

| Control | Limited control over production and quality processes | Full control over manufacturing and quality control |

| Scalability | Easy to scale production up or down | Scaling requires significant investment and time |

| Lead Time | Potential longer lead times due to third-party schedules | Faster turnaround times with internal scheduling |

| Expertise | Access to co-packer's specialized knowledge and technology | Requires in-house technical expertise and training |

| Flexibility | Limited customization options based on co-packer capabilities | High flexibility in product innovation and customization |

| Risk | Dependency on third-party reliability and compliance | Responsibility for compliance and risk management internally |

Introduction to Co-packing and In-house Manufacturing

Co-packing involves outsourcing the packaging and sometimes production of food products to a third-party manufacturer specializing in efficient, scalable operations. In-house manufacturing allows food companies to control the entire production process, ensuring strict quality standards and customization flexibility. Both methods impact cost structures, production timelines, and product consistency within the food industry.

Defining Co-packing in the Food Industry

Co-packing in the food industry involves outsourcing the packaging and sometimes production processes to specialized third-party companies, allowing brands to focus on product development and marketing. These co-packers manage tasks such as filling, labeling, and sealing, ensuring compliance with food safety regulations and industry standards. Outsourcing to co-packers can reduce capital investment and increase scalability compared to in-house manufacturing.

What is In-house Manufacturing?

In-house manufacturing refers to the process where a food company produces its products within its own facilities, controlling every stage from raw ingredient sourcing to final packaging. This method ensures strict quality control, quicker turnaround times, and the ability to customize recipes or production schedules according to market demands. Companies investing in in-house manufacturing often benefit from reduced costs over time and enhanced brand consistency compared to outsourcing or co-packing alternatives.

Cost Analysis: Co-packing vs In-house Manufacturing

Co-packing often reduces upfront capital investment, lowering fixed costs compared to in-house manufacturing, which requires significant expenditure on equipment, labor, and facility maintenance. Variable costs for co-packing fluctuate with order volume, offering scalability and reduced risk, whereas in-house production entails consistent labor and operational expenses regardless of output levels. Analyzing total cost of ownership reveals that co-packing favors companies with fluctuating demand and limited capital, while in-house manufacturing benefits those with stable, high-volume production seeking greater control over quality and process.

Scalability and Flexibility Considerations

Co-packing offers greater scalability by allowing food businesses to quickly adjust production volumes based on market demand, reducing the need for significant capital investment in manufacturing facilities. In-house manufacturing provides enhanced flexibility over product customization and ingredient control but may face limitations in scaling operations rapidly due to equipment capacity and workforce constraints. Evaluating scalability and flexibility is critical for food companies aiming to balance cost efficiency with the ability to innovate and respond to changing consumer preferences.

Quality Control and Food Safety Implications

Co-packing offers specialized quality control protocols tailored to large-scale production, often adhering to stringent food safety certifications such as GMP and HACCP, which can minimize contamination risks. In-house manufacturing allows for direct oversight of each stage in the production process, enabling immediate response to quality deviations and customized sanitation measures. Evaluating the balance between cost, scalability, and food safety standards is critical when choosing between co-packing and in-house manufacturing for food products.

Speed to Market: Comparing Production Timelines

Co-packing significantly reduces production timelines by leveraging specialized facilities and experienced staff, enabling faster speed to market compared to in-house manufacturing. In-house production often faces longer setup times due to equipment procurement, staff training, and production scaling challenges. Brands aiming for quick market entry typically prefer co-packing to streamline operations and meet consumer demand promptly.

Intellectual Property and Confidentiality Factors

Co-packing in food production involves sharing proprietary recipes and processes with external manufacturers, increasing risks related to intellectual property theft and confidentiality breaches. In-house manufacturing provides greater control over sensitive formulations and trade secrets, ensuring tighter security and safeguarding unique product innovations. Companies prioritizing IP protection often prefer in-house production to minimize exposure of valuable confidential information.

Case Studies: Success Stories and Challenges

Case studies reveal that co-packing enables food brands like Chobani to scale rapidly by leveraging specialized manufacturing expertise and flexible production capacity, reducing capital investment and operational risks. In contrast, in-house manufacturing offers companies like Amy's Kitchen full control over quality and process innovation but requires significant upfront costs and can limit scalability. Challenges in co-packing include dependency on third-party timelines and quality consistency, while in-house operations face hurdles in maintaining efficiency and managing resource allocation during demand fluctuations.

Choosing the Right Manufacturing Model for Your Food Brand

Evaluating co-packing versus in-house manufacturing hinges on your food brand's scale, budget, and quality control needs. Co-packing offers advantages like reduced overhead and faster production but may limit customization and control over ingredients. In-house manufacturing demands higher initial investment and operational expertise but ensures full oversight of product quality, branding, and agile innovation.

Co-packing vs In-house Manufacturing Infographic

productdif.com

productdif.com