SMD assembly offers higher component density and faster production times compared to through-hole assembly, making it ideal for compact and complex electronic devices. Through-hole assembly provides stronger mechanical connections and better durability for components subject to physical stress. Selecting between SMD and through-hole assembly depends on the design requirements, reliability needs, and manufacturing cost considerations of the electronic product.

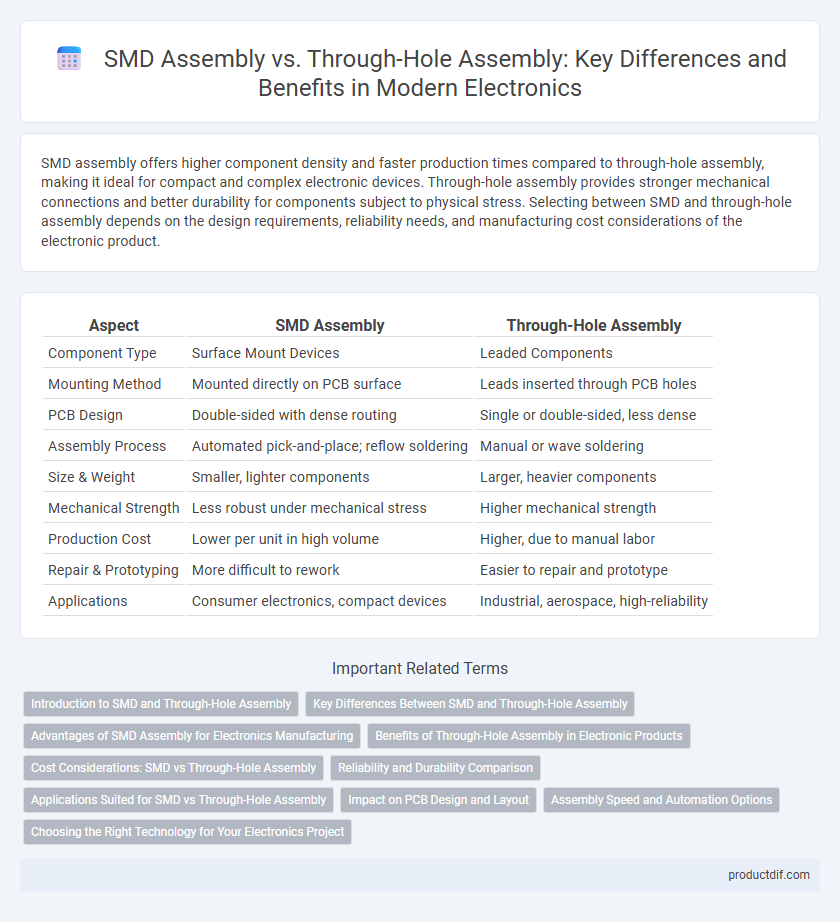

Table of Comparison

| Aspect | SMD Assembly | Through-Hole Assembly |

|---|---|---|

| Component Type | Surface Mount Devices | Leaded Components |

| Mounting Method | Mounted directly on PCB surface | Leads inserted through PCB holes |

| PCB Design | Double-sided with dense routing | Single or double-sided, less dense |

| Assembly Process | Automated pick-and-place; reflow soldering | Manual or wave soldering |

| Size & Weight | Smaller, lighter components | Larger, heavier components |

| Mechanical Strength | Less robust under mechanical stress | Higher mechanical strength |

| Production Cost | Lower per unit in high volume | Higher, due to manual labor |

| Repair & Prototyping | More difficult to rework | Easier to repair and prototype |

| Applications | Consumer electronics, compact devices | Industrial, aerospace, high-reliability |

Introduction to SMD and Through-Hole Assembly

Surface-Mount Device (SMD) assembly involves placing components directly onto the surface of printed circuit boards (PCBs), enabling higher component density and automated manufacturing processes. Through-hole assembly requires inserting component leads into pre-drilled holes on the PCB, providing strong mechanical bonds and suitability for components subjected to mechanical stress. Both techniques play crucial roles in electronics manufacturing, with SMD favored for compact designs and through-hole preferred for robust applications.

Key Differences Between SMD and Through-Hole Assembly

SMD assembly uses surface-mount technology to place small, lightweight components directly on the PCB surface, enabling higher circuit density and automated production for faster assembly. Through-hole assembly involves inserting component leads through drilled holes on the PCB, providing stronger mechanical bonds ideal for components subject to mechanical stress. Key differences include component size, assembly speed, and mechanical strength, with SMD favoring compact designs and efficiency, while through-hole offers durability.

Advantages of SMD Assembly for Electronics Manufacturing

Surface-Mount Device (SMD) assembly offers significant advantages in electronics manufacturing, including higher component density on printed circuit boards (PCBs), enabling more compact and lightweight designs. Its automated assembly process ensures faster production speeds and reduces labor costs, enhancing overall manufacturing efficiency. Moreover, SMD components exhibit superior electrical performance and reliability due to shorter lead lengths and improved thermal management.

Benefits of Through-Hole Assembly in Electronic Products

Through-hole assembly offers superior mechanical strength, making it ideal for components subjected to mechanical stress or high-reliability applications like aerospace and automotive electronics. This method ensures strong, durable connections through plated holes on the PCB, enhancing thermal dissipation and long-term stability. Through-hole technology is advantageous for prototyping and components requiring easy manual inspection, repair, or replacement.

Cost Considerations: SMD vs Through-Hole Assembly

Surface Mount Device (SMD) assembly typically reduces manufacturing costs due to automated placement and smaller component sizes, allowing higher density on printed circuit boards (PCBs). In contrast, through-hole assembly incurs higher labor and material costs because of manual insertion and larger component footprints. Cost efficiency of SMD is especially significant in high-volume production where throughput and material savings scale effectively.

Reliability and Durability Comparison

SMD assembly offers higher reliability due to smaller solder joints and reduced mechanical stress, enhancing performance in high-frequency circuits. Through-hole assembly provides superior durability for components exposed to mechanical strain, ideal for heavy or high-vibration environments. Both methods optimize circuit board longevity, but SMD excels in compact, precision applications while through-hole suits rugged industrial uses.

Applications Suited for SMD vs Through-Hole Assembly

Surface Mount Device (SMD) assembly excels in high-density, compact electronics such as smartphones, laptops, and wearable devices due to its smaller component size and automated placement. Through-hole assembly is preferred for applications requiring strong mechanical connections and durability, including automotive electronics, military hardware, and power equipment. SMD suits mass production and miniaturization, while through-hole is ideal for prototypes, high-stress environments, and large components like transformers.

Impact on PCB Design and Layout

SMD assembly offers higher component density and enables more compact PCB designs due to smaller package sizes and double-sided mounting capabilities, significantly improving signal integrity and reducing parasitic inductance. Through-hole assembly requires larger PCB real estate and often results in more complex routing because components must pass through drilled holes, affecting layer count and mechanical stability. Optimizing PCB layout for SMD assembly enhances manufacturing efficiency and supports high-frequency applications, while through-hole designs prioritize durability and mechanical strength in harsh environments.

Assembly Speed and Automation Options

SMD assembly offers significantly faster production times due to its compatibility with automated pick-and-place machines, enabling high-volume manufacturing with precision. Through-hole assembly requires manual insertion or wave soldering, which slows down the process and limits automation integration. The high-speed capabilities of SMD assembly result in reduced labor costs and increased throughput, making it the preferred choice for modern electronics manufacturing.

Choosing the Right Technology for Your Electronics Project

SMD assembly offers higher component density and faster automated production, making it ideal for compact, high-volume electronics. Through-hole assembly provides stronger mechanical bonds, suitable for components exposed to mechanical stress or requiring frequent repairs. Selecting the right technology depends on project requirements like size constraints, durability, and manufacturing scale.

SMD Assembly vs Through-Hole Assembly Infographic

productdif.com

productdif.com