Laser-cut wood blanks provide precise, consistent shapes ideal for intricate crafting projects, ensuring clean edges and uniformity that hand-cut wood shapes often lack. Hand-cut wood shapes offer a unique, artisanal touch with slight variations that create character and authenticity, making them perfect for personalized, rustic designs. Choosing between the two depends on whether precision or handcrafted uniqueness is the priority in your crafting supply needs.

Table of Comparison

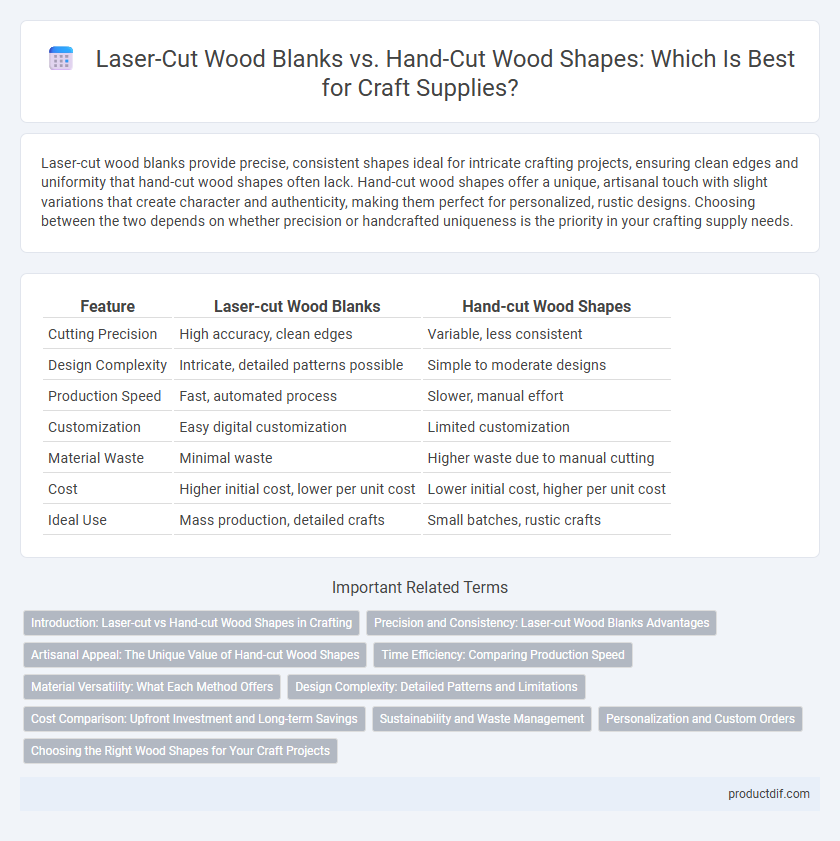

| Feature | Laser-cut Wood Blanks | Hand-cut Wood Shapes |

|---|---|---|

| Cutting Precision | High accuracy, clean edges | Variable, less consistent |

| Design Complexity | Intricate, detailed patterns possible | Simple to moderate designs |

| Production Speed | Fast, automated process | Slower, manual effort |

| Customization | Easy digital customization | Limited customization |

| Material Waste | Minimal waste | Higher waste due to manual cutting |

| Cost | Higher initial cost, lower per unit cost | Lower initial cost, higher per unit cost |

| Ideal Use | Mass production, detailed crafts | Small batches, rustic crafts |

Introduction: Laser-cut vs Hand-cut Wood Shapes in Crafting

Laser-cut wood blanks offer precision and uniformity, ensuring consistent shapes for intricate crafting projects. Hand-cut wood shapes provide unique, artisanal qualities with subtle variations that appeal to bespoke and rustic designs. Choosing between laser-cut and hand-cut depends on the desired balance between accuracy and handcrafted character in craft supplies.

Precision and Consistency: Laser-cut Wood Blanks Advantages

Laser-cut wood blanks offer superior precision and consistency compared to hand-cut wood shapes, delivering exact dimensions with clean, intricate edges every time. The computerized laser technology minimizes human error and ensures uniformity across large batches, making them ideal for detailed crafts and mass production. This level of accuracy enhances the finished product's quality, especially for intricate designs requiring tight tolerances.

Artisanal Appeal: The Unique Value of Hand-cut Wood Shapes

Hand-cut wood shapes offer an artisanal appeal unmatched by laser-cut wood blanks, showcasing the skill and individuality of the craftsperson. Each hand-cut piece features subtle variations and organic imperfections that enhance its unique character and aesthetic value. This traditional approach results in artful creations prized for their authenticity and personalized touch in craft supply projects.

Time Efficiency: Comparing Production Speed

Laser-cut wood blanks offer significantly faster production speeds due to automated precision cutting, enabling bulk creation of intricate shapes within minutes. Hand-cut wood shapes require more time and skilled labor, often resulting in slower output and higher production costs. For large-scale projects, laser cutting enhances time efficiency, reducing turnaround times and increasing overall productivity in craft supply manufacturing.

Material Versatility: What Each Method Offers

Laser-cut wood blanks provide exceptional precision and consistency, allowing for intricate designs across a wide range of wood types such as birch, maple, and cherry. Hand-cut wood shapes offer unmatched material versatility by enabling artisans to select and work with unique woods, including reclaimed and exotic varieties, adapting to grain patterns and textures. Both methods deliver distinct advantages: laser cutting excels in detailed repeatability for standardized projects, while hand-cutting supports creativity with diverse and individualized wood materials.

Design Complexity: Detailed Patterns and Limitations

Laser-cut wood blanks enable intricate and highly detailed patterns with precision that hand-cut wood shapes often cannot achieve due to manual limitations. The laser cutting process allows for consistent reproducibility of complex designs, including fine lines and delicate curves, enhancing customization options for craft projects. Hand-cut wood shapes may introduce slight imperfections and are generally restricted by the cutter's skill level, limiting the intricacy of pattern detail.

Cost Comparison: Upfront Investment and Long-term Savings

Laser-cut wood blanks typically require a higher upfront investment due to advanced machinery and precision technology, but they offer consistent quality and minimal material waste, leading to long-term savings. Hand-cut wood shapes involve lower initial costs, relying on manual tools and labor, yet potential variability in dimensions and higher material waste can increase expenses over time. Evaluating these options depends on factors like production volume, finish precision, and budget constraints in the craft supply industry.

Sustainability and Waste Management

Laser-cut wood blanks offer greater precision and reduce material waste compared to hand-cut wood shapes, optimizing resource use and enhancing sustainability in craft supply production. The automated cutting process minimizes offcuts and allows for efficient nesting patterns that maximize wood utilization, lowering environmental impact. Hand-cut wood shapes often result in higher scrap rates and inconsistent sizing, contributing to increased waste and less sustainable manufacturing practices.

Personalization and Custom Orders

Laser-cut wood blanks offer unparalleled precision and consistency, enabling intricate designs and detailed personalization that hand-cut wood shapes may struggle to achieve. Custom orders with laser-cut blanks ensure exact replication of complex patterns, making them ideal for personalized craft projects requiring uniformity. Hand-cut wood shapes provide a more rustic, artisanal feel, suited for unique, one-of-a-kind creations where slight variations enhance the personalized touch.

Choosing the Right Wood Shapes for Your Craft Projects

Laser-cut wood blanks provide precision and uniformity, ideal for intricate designs and detailed craft projects requiring consistent shapes. Hand-cut wood shapes offer unique, artisanal character with slight variations that enhance the handmade appeal and customizable options for personalized crafts. Selecting the right wood shapes depends on project complexity, desired finish, and whether uniformity or individuality is prioritized in the craftsmanship.

Laser-cut Wood Blanks vs Hand-cut Wood Shapes Infographic

productdif.com

productdif.com