Laser-cut embellishments offer precise, intricate designs with clean edges, making them ideal for detailed craft projects that require fine customization. Die-cut embellishments provide quick, consistent shapes perfect for bulk crafting but may lack the sharp detail achievable with laser cutting. Choosing between the two depends on the desired level of detail and production volume for your craft supply needs.

Table of Comparison

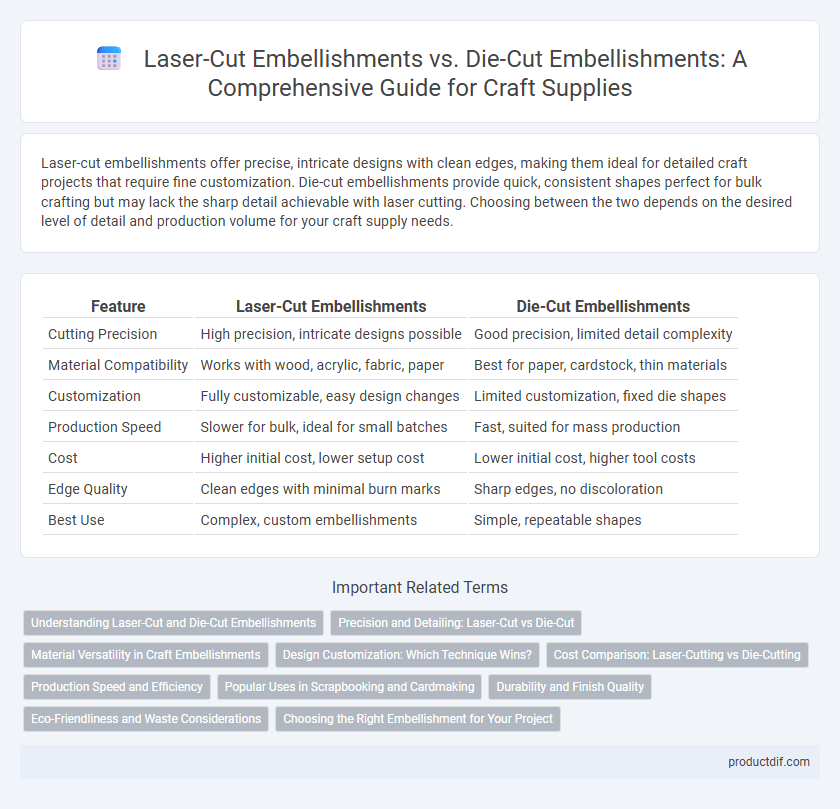

| Feature | Laser-Cut Embellishments | Die-Cut Embellishments |

|---|---|---|

| Cutting Precision | High precision, intricate designs possible | Good precision, limited detail complexity |

| Material Compatibility | Works with wood, acrylic, fabric, paper | Best for paper, cardstock, thin materials |

| Customization | Fully customizable, easy design changes | Limited customization, fixed die shapes |

| Production Speed | Slower for bulk, ideal for small batches | Fast, suited for mass production |

| Cost | Higher initial cost, lower setup cost | Lower initial cost, higher tool costs |

| Edge Quality | Clean edges with minimal burn marks | Sharp edges, no discoloration |

| Best Use | Complex, custom embellishments | Simple, repeatable shapes |

Understanding Laser-Cut and Die-Cut Embellishments

Laser-cut embellishments offer intricate and precise designs achieved through focused laser beams, allowing for detailed patterns on materials like wood, acrylic, and leather. Die-cut embellishments rely on metal dies to stamp shapes from paper, fabric, or thin cardstock, making them ideal for mass production with consistent edges. Understanding the differences in material compatibility, design complexity, and production volume helps crafters choose between laser-cut and die-cut embellishments for their projects.

Precision and Detailing: Laser-Cut vs Die-Cut

Laser-cut embellishments achieve superior precision with intricate details by using focused laser beams that create clean, sharp edges ideal for complex designs. Die-cut embellishments rely on pre-shaped metal dies, offering consistent shapes but less capability for fine detail and delicate patterns compared to laser cutting. For craft projects demanding high-detail and accuracy, laser-cut embellishments provide enhanced versatility and refined craftsmanship.

Material Versatility in Craft Embellishments

Laser-cut embellishments offer superior material versatility, enabling precise cuts on wood, acrylic, leather, and fabric with intricate detail and minimal distortion. Die-cut embellishments, while efficient for high-volume production, are generally limited to thinner materials like paper and cardstock due to the physical constraints of the dies. Craft enthusiasts seeking diverse material options and detailed designs often prefer laser cutting for its adaptability and clean finish across various substrates.

Design Customization: Which Technique Wins?

Laser-cut embellishments offer superior design customization with intricate details and complex patterns achievable through precise computer-guided cutting. Die-cut embellishments, while cost-effective for high-volume production, are limited by fixed metal dies, restricting design flexibility and rapid changes. For unique, highly tailored craft projects, laser-cutting stands out as the preferred technique due to its versatility in material types and design intricacy.

Cost Comparison: Laser-Cutting vs Die-Cutting

Laser-cut embellishments often incur higher initial costs due to sophisticated equipment and detailed customization capabilities, making them ideal for small batches or complex designs. Die-cut embellishments generally offer lower per-unit costs, benefiting large-scale production runs with consistent shapes and simpler designs. Evaluating project volume, complexity, and budget constraints is essential to determine the most cost-effective technique between laser-cut and die-cut embellishments.

Production Speed and Efficiency

Laser-cut embellishments offer faster production speed due to precise digital control, enabling rapid customization without the need for physical dies. Die-cut embellishments require creating and setting up metal dies, which slows initial production but allows high-volume runs with consistent efficiency after setup. For small batches or intricate designs, laser cutting maximizes efficiency, while die-cutting is advantageous for large, repetitive production runs.

Popular Uses in Scrapbooking and Cardmaking

Laser-cut embellishments offer intricate designs and fine details ideal for delicate scrapbooking layers and personalized card accents, making them popular for custom projects with precision cuts. Die-cut embellishments provide consistent shapes and sturdy textures favored in bulk crafting, enhancing layouts with vibrant, uniform elements that are perfect for repetitive motifs in cardmaking and scrapbooking. Both techniques cater to specific creative needs, with laser-cut pieces excelling in finesse and die-cut supplies excelling in efficiency and uniformity.

Durability and Finish Quality

Laser-cut embellishments provide superior durability due to precise cuts made by high-powered lasers that minimize material stress, resulting in clean, intricate designs with smooth edges. Die-cut embellishments offer a consistent finish but may suffer from slight fraying or rough edges over time, especially on delicate materials, due to the mechanical pressure applied during cutting. The high precision of laser cutting typically produces a more refined finish, making it ideal for detailed craft projects requiring both durability and aesthetic quality.

Eco-Friendliness and Waste Considerations

Laser-cut embellishments produce less material waste due to precise cutting technology, making them a more eco-friendly option compared to die-cut embellishments, which often generate excess scraps from metal die use. Laser cutting requires minimal setup and eliminates the need for physical dies, reducing resource consumption and enabling on-demand production that minimizes overstock and inventory waste. Opting for laser-cut embellishments supports sustainability initiatives by lowering carbon footprint and promoting efficient material utilization in craft supply design.

Choosing the Right Embellishment for Your Project

Laser-cut embellishments offer precise, intricate designs ideal for detailed craft projects, while die-cut embellishments provide consistent shapes perfect for mass production and simpler patterns. Selecting between laser-cut and die-cut depends on your project's complexity, budget, and desired finish, with laser cuts excelling in customization and die cuts in efficiency. Understanding material compatibility and production scale ensures the right embellishment enhances your craft's aesthetic and durability.

Laser-cut embellishments vs Die-cut embellishments Infographic

productdif.com

productdif.com