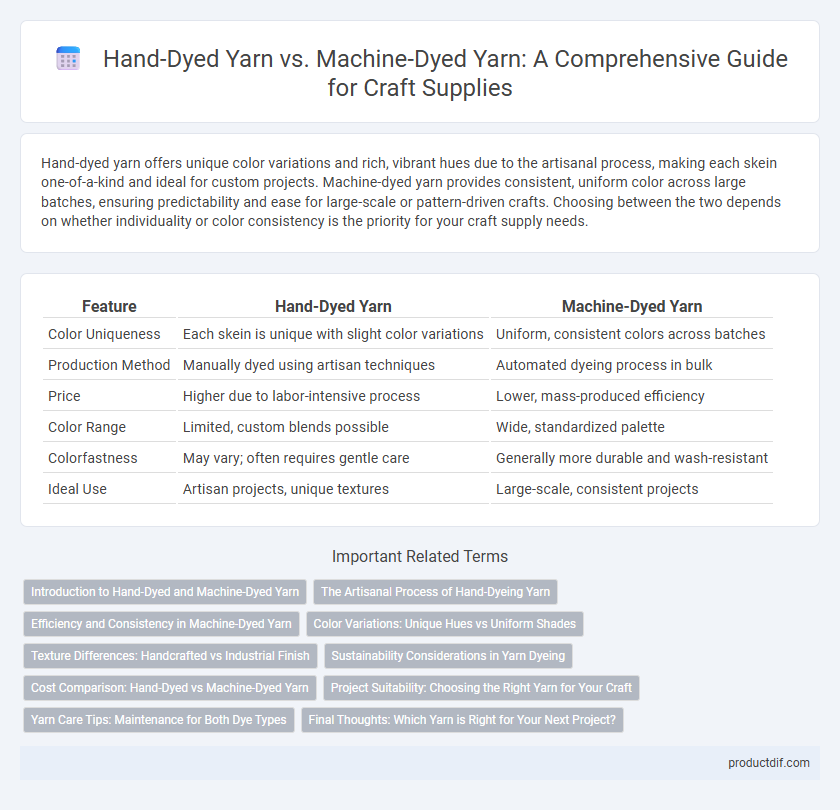

Hand-dyed yarn offers unique color variations and rich, vibrant hues due to the artisanal process, making each skein one-of-a-kind and ideal for custom projects. Machine-dyed yarn provides consistent, uniform color across large batches, ensuring predictability and ease for large-scale or pattern-driven crafts. Choosing between the two depends on whether individuality or color consistency is the priority for your craft supply needs.

Table of Comparison

| Feature | Hand-Dyed Yarn | Machine-Dyed Yarn |

|---|---|---|

| Color Uniqueness | Each skein is unique with slight color variations | Uniform, consistent colors across batches |

| Production Method | Manually dyed using artisan techniques | Automated dyeing process in bulk |

| Price | Higher due to labor-intensive process | Lower, mass-produced efficiency |

| Color Range | Limited, custom blends possible | Wide, standardized palette |

| Colorfastness | May vary; often requires gentle care | Generally more durable and wash-resistant |

| Ideal Use | Artisan projects, unique textures | Large-scale, consistent projects |

Introduction to Hand-Dyed and Machine-Dyed Yarn

Hand-dyed yarn features unique color variations and rich texture, created by artisans applying dye manually to small yarn batches. Machine-dyed yarn offers uniform color consistency and higher production efficiency, using automated processes ideal for large-scale manufacturing. Choosing between hand-dyed and machine-dyed yarn impacts project aesthetics, dye saturation, and overall fiber quality.

The Artisanal Process of Hand-Dyeing Yarn

Hand-dyed yarn showcases a unique artisanal process where skilled dyers carefully apply colors in small batches, ensuring rich variations and depth unattainable by machine-dyeing techniques. This method highlights the craftsmanship involved, producing yarns with distinctive color gradients and organic imperfections that enhance texture and visual appeal in finished projects. Unlike the uniformity of machine-dyed yarn, hand-dyed yarn captures a personalized, one-of-a-kind aesthetic prized by knitters and crafters seeking originality.

Efficiency and Consistency in Machine-Dyed Yarn

Machine-dyed yarn offers superior efficiency with its ability to process large batches rapidly, reducing production time significantly compared to hand-dyed yarn. Consistency is a key advantage as machine-dyeing ensures uniform color saturation and repeatable results across all skeins. This predictability benefits manufacturers and crafters seeking reliable, standardized materials for large-scale or commercial projects.

Color Variations: Unique Hues vs Uniform Shades

Hand-dyed yarn exhibits unique hues with subtle color variations that create rich, one-of-a-kind textures ideal for artisanal projects. Machine-dyed yarn produces uniform shades, ensuring consistency and predictability in large-scale or pattern-specific crafting. These differences significantly impact the visual depth and individuality of finished textile products.

Texture Differences: Handcrafted vs Industrial Finish

Hand-dyed yarn features a unique texture with subtle variations and irregularities, creating a handcrafted, artisanal finish prized by crafters for its tactile richness. Machine-dyed yarn, in contrast, offers uniform texture and consistent color saturation, reflecting an industrial precision suited for mass production. The tactile contrast between the two highlights the artisanal appeal of hand-dyed yarn versus the dependable consistency of machine-dyed alternatives.

Sustainability Considerations in Yarn Dyeing

Hand-dyed yarn typically uses smaller batches and natural dyes, reducing chemical runoff and energy consumption compared to machine-dyed yarn produced in large-scale factories with synthetic dyes. Machine-dyed yarns often involve automated processes that can lead to higher water usage and increased waste but benefit from consistency and scalability. Choosing hand-dyed yarn supports sustainable craft practices by minimizing environmental impact through artisanal methods and eco-friendly dye options.

Cost Comparison: Hand-Dyed vs Machine-Dyed Yarn

Hand-dyed yarn typically costs more due to labor-intensive processes, small-batch production, and unique color variations that add artisanal value. Machine-dyed yarn benefits from economies of scale, lower labor expenses, and consistent color output, making it more affordable for mass production. Consumers often choose hand-dyed yarn for its exclusivity despite higher prices, whereas machine-dyed yarn suits budget-conscious projects requiring uniformity.

Project Suitability: Choosing the Right Yarn for Your Craft

Hand-dyed yarn offers unique color variations and richness, making it ideal for projects that require a personalized, artisanal touch such as scarves, shawls, and statement pieces. Machine-dyed yarn provides consistent color and uniformity, perfect for large projects or items needing color matching like sweaters, blankets, and baby clothing. Selecting the right yarn depends on whether project uniformity or one-of-a-kind aesthetics are the priority for your craft creation.

Yarn Care Tips: Maintenance for Both Dye Types

Hand-dyed yarn requires gentle hand washing with cold water and mild detergent to preserve its vibrant colors and prevent bleeding, while machine-dyed yarn can often withstand machine washing on a delicate cycle. Both dye types benefit from air drying flat and avoiding direct sunlight to maintain fiber integrity and colorfastness. Storing yarn in a cool, dry place away from moisture and pests ensures long-lasting quality regardless of dye method.

Final Thoughts: Which Yarn is Right for Your Next Project?

Hand-dyed yarn offers unique color variations and artisanal quality ideal for projects demanding individuality and texture depth. Machine-dyed yarn provides consistent color uniformity and is more cost-effective, perfect for large-scale or repetitive designs. Choosing the right yarn depends on balancing artistic expression with project requirements, timeline, and budget constraints.

Hand-dyed yarn vs Machine-dyed yarn Infographic

productdif.com

productdif.com