Glass etching creates intricate, detailed designs by applying acid or chemical solutions to the glass surface, offering precise control for delicate artwork. Sandblasting uses high-pressure abrasive materials to carve patterns into glass, ideal for deeper, textured effects and larger projects. Both methods enhance craft supplies by enabling unique customization, but glass etching suits fine detail while sandblasting excels in bold, durable finishes.

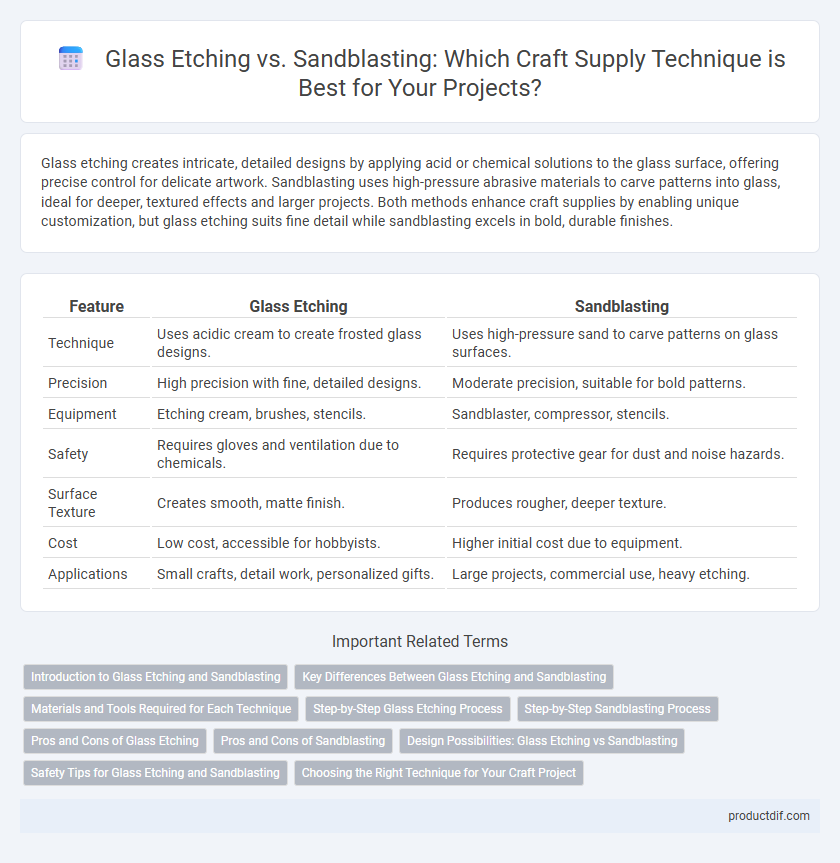

Table of Comparison

| Feature | Glass Etching | Sandblasting |

|---|---|---|

| Technique | Uses acidic cream to create frosted glass designs. | Uses high-pressure sand to carve patterns on glass surfaces. |

| Precision | High precision with fine, detailed designs. | Moderate precision, suitable for bold patterns. |

| Equipment | Etching cream, brushes, stencils. | Sandblaster, compressor, stencils. |

| Safety | Requires gloves and ventilation due to chemicals. | Requires protective gear for dust and noise hazards. |

| Surface Texture | Creates smooth, matte finish. | Produces rougher, deeper texture. |

| Cost | Low cost, accessible for hobbyists. | Higher initial cost due to equipment. |

| Applications | Small crafts, detail work, personalized gifts. | Large projects, commercial use, heavy etching. |

Introduction to Glass Etching and Sandblasting

Glass etching uses acidic cream or abrasive powders to create intricate designs on glass surfaces, producing a smooth, frosted finish ideal for detailed artwork. Sandblasting involves propelling fine abrasive particles at high velocity to carve patterns, offering greater depth and texture for bold, three-dimensional effects. Both techniques enhance glass crafts by providing durable, customizable surface decorations with unique aesthetic qualities.

Key Differences Between Glass Etching and Sandblasting

Glass etching uses acidic creams or gels to create detailed, shallow designs on glass surfaces, providing precision and fine textures ideal for intricate patterns. Sandblasting employs high-pressure abrasive particles to carve deeper, frosted textures into glass, allowing for more robust and durable finishes but with less fine detail. Key differences include the method of material removal, depth of engraving, and the level of detail achievable, impacting the final aesthetic and application.

Materials and Tools Required for Each Technique

Glass etching requires materials such as etching cream, stencils, and protective gloves to safely apply the acidic substance that creates frosted designs, while tools often include brushes or applicators for precise coverage. Sandblasting involves a sandblaster or air compressor, abrasive media like aluminum oxide or silicon carbide, and protective gear including masks and gloves to handle high-pressure abrasive particles that carve into the glass surface. Both techniques demand specific safety equipment and preparation, but sandblasting typically requires more specialized and costly machinery compared to the simpler materials needed for glass etching.

Step-by-Step Glass Etching Process

Glass etching involves applying a stencil or adhesive vinyl to protect specific areas, then using an etching cream to chemically abrade the exposed glass surface for detailed designs. The process starts with cleaning the glass thoroughly, followed by applying the stencil carefully to ensure sharp edges, then evenly spreading the etching cream for the recommended time before rinsing it off under water. Unlike sandblasting, which uses compressed air and abrasive materials for deeper engraving, glass etching offers precise control for delicate, intricate patterns ideal for craft projects.

Step-by-Step Sandblasting Process

Step-by-step sandblasting begins with securely masking the glass surface using adhesive stencils or vinyl to protect areas not intended for etching. The sandblaster propels fine abrasive particles at high velocity, meticulously eroding the unmasked glass to create detailed, frosted designs. Finishing involves removing the mask and thoroughly cleaning the glass to reveal a precisely textured, durable etched pattern distinct from traditional acid-based etching methods.

Pros and Cons of Glass Etching

Glass etching offers precise, intricate designs with a smooth matte finish that enhances aesthetic appeal and is ideal for detailed artwork. It is less abrasive than sandblasting, reducing the risk of cracking or damaging delicate glass surfaces and allowing for easier cleanup. However, glass etching typically requires longer processing time and chemical handling, making it less suited for large-scale or heavy-duty projects compared to sandblasting.

Pros and Cons of Sandblasting

Sandblasting offers precise and detailed designs on glass with a uniform matte finish, making it ideal for intricate patterns and large-scale projects. However, it requires specialized equipment, can be more labor-intensive, and may pose safety risks due to airborne particles, necessitating proper ventilation and protective gear. Despite these challenges, sandblasting provides depth and texture that are difficult to replicate with other etching methods.

Design Possibilities: Glass Etching vs Sandblasting

Glass etching offers precision and fine detail, ideal for intricate patterns and delicate designs on glass surfaces, while sandblasting enables deeper texture and bolder, more pronounced effects suitable for larger areas or rougher finishes. Etching uses chemical or acidic compounds to create subtle frosted designs that preserve clarity, whereas sandblasting employs high-pressure abrasive particles, allowing for varied depth and tactile contrast. Both techniques provide unique design possibilities, with glass etching favored for subtle elegance and sandblasting for dramatic, textured artistry.

Safety Tips for Glass Etching and Sandblasting

When working with glass etching and sandblasting, wear protective eyewear and gloves to prevent injury from glass shards or abrasive particles. Use a well-ventilated workspace or respiratory protection to avoid inhaling fine silica dust, which can cause respiratory issues. Always follow manufacturer guidelines for handling etching creams and abrasive materials to ensure safe and effective crafting.

Choosing the Right Technique for Your Craft Project

Glass etching offers precise, detailed designs ideal for small, intricate craft projects, while sandblasting provides a more versatile and deeper finish suitable for larger surfaces and textured effects. Consider the level of detail, project size, and material thickness when choosing between glass etching and sandblasting techniques. Safety equipment and proper ventilation are essential for both methods to ensure a safe crafting environment.

Glass etching vs Sandblasting Infographic

productdif.com

productdif.com