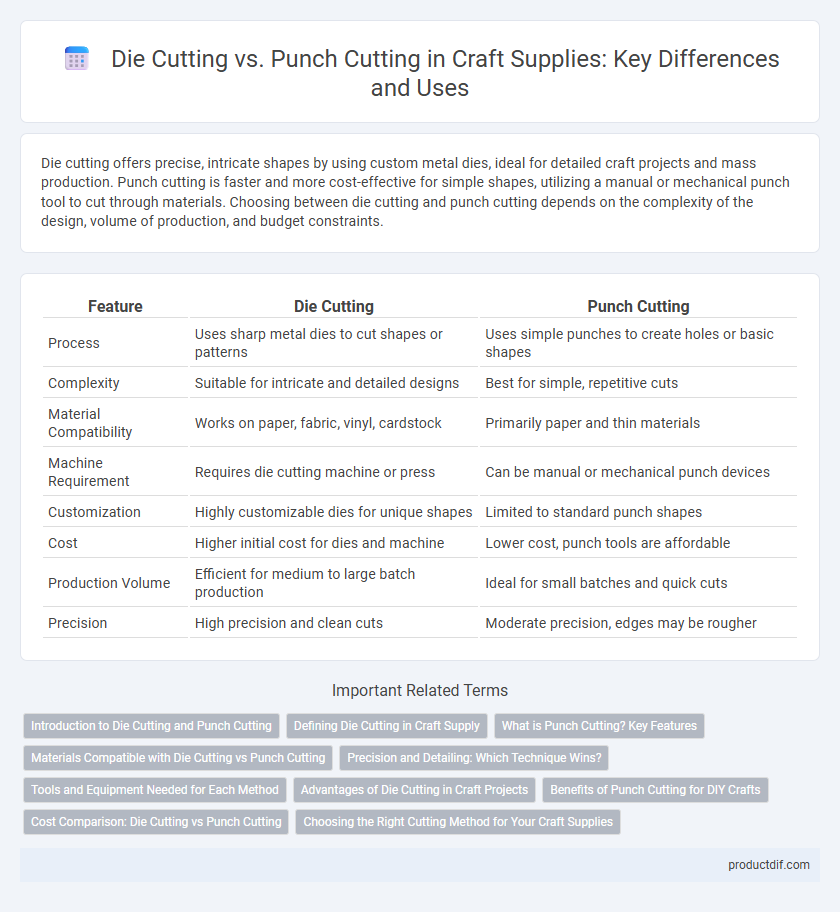

Die cutting offers precise, intricate shapes by using custom metal dies, ideal for detailed craft projects and mass production. Punch cutting is faster and more cost-effective for simple shapes, utilizing a manual or mechanical punch tool to cut through materials. Choosing between die cutting and punch cutting depends on the complexity of the design, volume of production, and budget constraints.

Table of Comparison

| Feature | Die Cutting | Punch Cutting |

|---|---|---|

| Process | Uses sharp metal dies to cut shapes or patterns | Uses simple punches to create holes or basic shapes |

| Complexity | Suitable for intricate and detailed designs | Best for simple, repetitive cuts |

| Material Compatibility | Works on paper, fabric, vinyl, cardstock | Primarily paper and thin materials |

| Machine Requirement | Requires die cutting machine or press | Can be manual or mechanical punch devices |

| Customization | Highly customizable dies for unique shapes | Limited to standard punch shapes |

| Cost | Higher initial cost for dies and machine | Lower cost, punch tools are affordable |

| Production Volume | Efficient for medium to large batch production | Ideal for small batches and quick cuts |

| Precision | High precision and clean cuts | Moderate precision, edges may be rougher |

Introduction to Die Cutting and Punch Cutting

Die cutting uses metal dies to cut shapes from materials such as paper, fabric, and leather with precision and consistency, making it ideal for detailed craft projects. Punch cutting employs a hand-operated or mechanical punch tool to create holes or simple shapes, often used for quick, repetitive cuts in materials like cardstock. Both techniques enhance crafting by enabling intricate designs, but die cutting is preferred for complexity and volume while punch cutting suits straightforward tasks.

Defining Die Cutting in Craft Supply

Die cutting in craft supply involves using a specialized machine and metal dies to cut precise shapes from materials like paper, fabric, and leather. This technique enables intricate and consistent designs, enhancing craft projects with professional-quality results. Unlike punch cutting, which relies on manual force for basic shapes, die cutting provides greater versatility and detail.

What is Punch Cutting? Key Features

Punch cutting is a manual crafting technique that uses a die with sharp edges to create precise shapes by physically punching through materials like paper, fabric, or thin metal. Key features include its ability to produce consistent, clean cuts, ease of use without complex machinery, and suitability for small to medium-scale craft projects. Punch cutting tools often come in a variety of shapes and sizes, allowing crafters to create detailed embellishments and designs efficiently.

Materials Compatible with Die Cutting vs Punch Cutting

Die cutting is compatible with a wide range of materials including cardstock, fabric, leather, foam, and thin metals, allowing for precise, intricate shapes ideal for detailed projects. Punch cutting is typically limited to thinner materials like paper, vellum, and lightweight plastic sheets due to the mechanical constraints of punch tools. Choosing between die cutting and punch cutting depends on the material thickness and desired detail, with die cutting offering greater versatility for diverse crafting supplies.

Precision and Detailing: Which Technique Wins?

Die cutting excels in precision and intricate detailing, offering consistent, clean cuts ideal for complex shapes and fine patterns in craft supplies. Punch cutting, while effective for simple, repetitive shapes, often lacks the detailed accuracy and smooth edges achievable with die cutting. For projects demanding high precision and elaborate designs, die cutting remains the superior technique.

Tools and Equipment Needed for Each Method

Die cutting requires a die cutter machine, a custom-designed metal die, and cutting mats to achieve precise shapes in materials like paper, fabric, or leather. Punch cutting involves handheld punches or rotary punches, which are manually applied to cut specific shapes or holes, often used for simpler or smaller projects. Both methods necessitate appropriate safety gear, but die cutting offers automation and repeatability, whereas punch cutting allows greater portability and flexibility.

Advantages of Die Cutting in Craft Projects

Die cutting offers unparalleled precision and consistency in craft projects, enabling intricate designs that punch cutting cannot achieve. It supports a wide range of materials, including paper, fabric, and thin metal, making it versatile for various crafting needs. The automated process of die cutting also increases efficiency and reduces waste, enhancing overall productivity in craft supply usage.

Benefits of Punch Cutting for DIY Crafts

Punch cutting offers precise and consistent shapes, making it ideal for intricate DIY craft projects. This method saves time by quickly producing multiple identical pieces, enhancing productivity for crafters. Durable steel dies ensure clean cuts on various materials, improving the overall quality and finish of handmade creations.

Cost Comparison: Die Cutting vs Punch Cutting

Die cutting generally incurs higher upfront costs due to the need for custom metal dies, which can be expensive to produce but offer precision and durability for large runs. Punch cutting features lower initial expenses by utilizing simpler tools, making it more cost-effective for small batches or prototypes but less efficient for mass production. Evaluating project volume and design complexity is crucial when deciding between die cutting and punch cutting to optimize overall cost-efficiency in craft supply manufacturing.

Choosing the Right Cutting Method for Your Craft Supplies

Die cutting offers precise, intricate shapes ideal for detailed craft projects, using metal dies to cut multiple layers simultaneously. Punch cutting is better suited for simpler shapes and smaller runs, providing quick, clean cuts through single layers of craft materials. Selecting the right method depends on your project complexity, material thickness, and production volume to maximize efficiency and quality.

Die Cutting vs Punch Cutting Infographic

productdif.com

productdif.com