Riveted handles offer superior durability and a classic look, ensuring a secure and stable grip that resists loosening over time. Welded handles provide a sleek design with smooth surfaces, making cleaning easier and reducing trapped dirt or food particles. Choosing between riveted and welded handles depends on your preference for long-term strength versus streamlined maintenance.

Table of Comparison

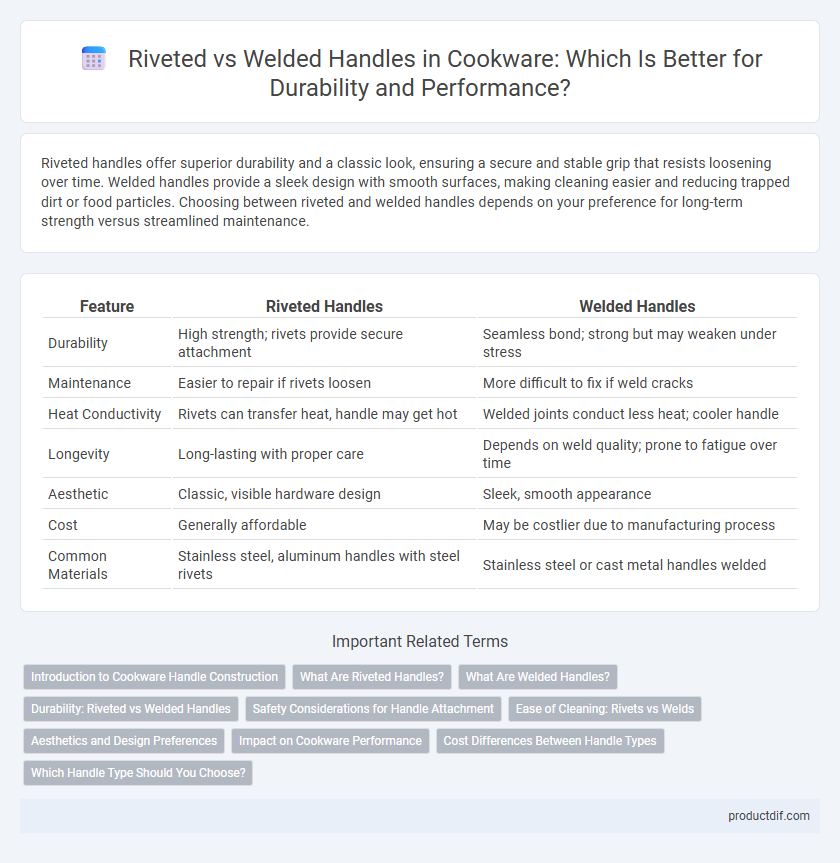

| Feature | Riveted Handles | Welded Handles |

|---|---|---|

| Durability | High strength; rivets provide secure attachment | Seamless bond; strong but may weaken under stress |

| Maintenance | Easier to repair if rivets loosen | More difficult to fix if weld cracks |

| Heat Conductivity | Rivets can transfer heat, handle may get hot | Welded joints conduct less heat; cooler handle |

| Longevity | Long-lasting with proper care | Depends on weld quality; prone to fatigue over time |

| Aesthetic | Classic, visible hardware design | Sleek, smooth appearance |

| Cost | Generally affordable | May be costlier due to manufacturing process |

| Common Materials | Stainless steel, aluminum handles with steel rivets | Stainless steel or cast metal handles welded |

Introduction to Cookware Handle Construction

Riveted handles consist of metal fasteners that securely attach the handle to the cookware, offering durability and a traditional look favored in professional kitchens. Welded handles are fused directly to the cookware body through high-heat processes, creating a seamless connection that enhances strength and simplifies cleaning. Understanding the differences in handle construction helps in choosing cookware based on maintenance preferences and long-term reliability.

What Are Riveted Handles?

Riveted handles are securely attached to cookware using metal pins or rivets that pass through both the handle and the pot or pan, providing durability and stability. This construction method offers superior strength compared to welded handles, especially in heavy-duty or professional-grade cookware. Riveted handles also allow for easier grip and better heat resistance, making them ideal for frequent cooking and high-temperature use.

What Are Welded Handles?

Welded handles in cookware are securely attached by fusing metal parts together using high heat, creating a seamless, smooth connection. This method enhances durability and prevents loosening over time compared to riveted handles, which use visible metal fasteners. Welded handles also provide easier cleaning as there are no crevices for food particles to accumulate, making them ideal for maintaining hygienic kitchen environments.

Durability: Riveted vs Welded Handles

Riveted handles offer superior durability due to their multiple fasteners that securely attach the handle to the cookware, minimizing the risk of loosening or detachment over time. Welded handles provide a seamless connection, but may be more prone to stress fractures or weakening with frequent use and high heat exposure. Overall, riveted handles are preferred for long-lasting cookware that withstands heavy use and rigorous kitchen conditions.

Safety Considerations for Handle Attachment

Riveted handles provide a secure, durable attachment by mechanically fastening the handle to the cookware, reducing the risk of loosening over time and ensuring stability during use. Welded handles eliminate weakness points by fusing the handle directly to the pot or pan, enhancing safety by preventing handle detachment under heavy use or high temperatures. Both methods aim to minimize accidents and guarantee reliable handling, but riveted handles may require periodic maintenance checks to avoid wear at the rivet sites.

Ease of Cleaning: Rivets vs Welds

Riveted handles often trap food particles and grease around the rivet heads, making them harder to clean thoroughly compared to welded handles. Welded handles provide a seamless connection that prevents dirt buildup, streamlining maintenance and sanitation. Choosing cookware with welded handles enhances ease of cleaning and hygiene in the kitchen.

Aesthetics and Design Preferences

Riveted handles offer a classic, sturdy look often favored in traditional cookware designs, providing visible metal rivets that enhance a rustic or industrial aesthetic. Welded handles contribute to a sleek, seamless appearance ideal for modern kitchens, emphasizing minimalism and ease of cleaning. Design preferences depend on whether users prioritize visual appeal that complements vintage styles or a streamlined, contemporary finish.

Impact on Cookware Performance

Riveted handles provide superior durability and secure attachment, minimizing the risk of loosening over time, which enhances overall cookware longevity and safety. Welded handles offer a sleek, seamless design that improves heat distribution and makes cleaning easier by eliminating crevices where food particles can accumulate. Choosing between riveted and welded handles directly impacts cookware performance in terms of stability, heat conduction, and maintenance convenience.

Cost Differences Between Handle Types

Riveted handles typically increase cookware production costs due to additional materials and labor required for secure fastening, resulting in higher retail prices compared to welded handles. Welded handles, favored for streamlined manufacturing and durability, generally reduce overall costs by eliminating rivets and simplifying assembly. Price variations between riveted and welded handle cookware often reflect differences in craftsmanship, longevity, and consumer preference for handle stability.

Which Handle Type Should You Choose?

Riveted handles offer superior durability and a secure attachment, making them ideal for heavy-duty cookware frequently used in professional kitchens. Welded handles provide a sleek design with fewer crevices for food buildup, enhancing ease of cleaning and preventing bacterial growth. Choosing between riveted and welded handles depends on your cooking style: prioritize riveted for strength and longevity or welded for streamlined maintenance and modern aesthetics.

Riveted Handles vs Welded Handles Infographic

productdif.com

productdif.com