Clad aluminum cookware offers superior heat distribution with layers of aluminum bonded to stainless steel, ensuring quick and even cooking with enhanced durability. Hard-anodized cookware features aluminum treated through an electrochemical process to create a hard, non-reactive surface that resists scratches and corrosion while providing excellent heat retention. Choosing between clad aluminum and hard-anodized depends on the balance between conductivity and surface hardness preferred for daily cooking needs.

Table of Comparison

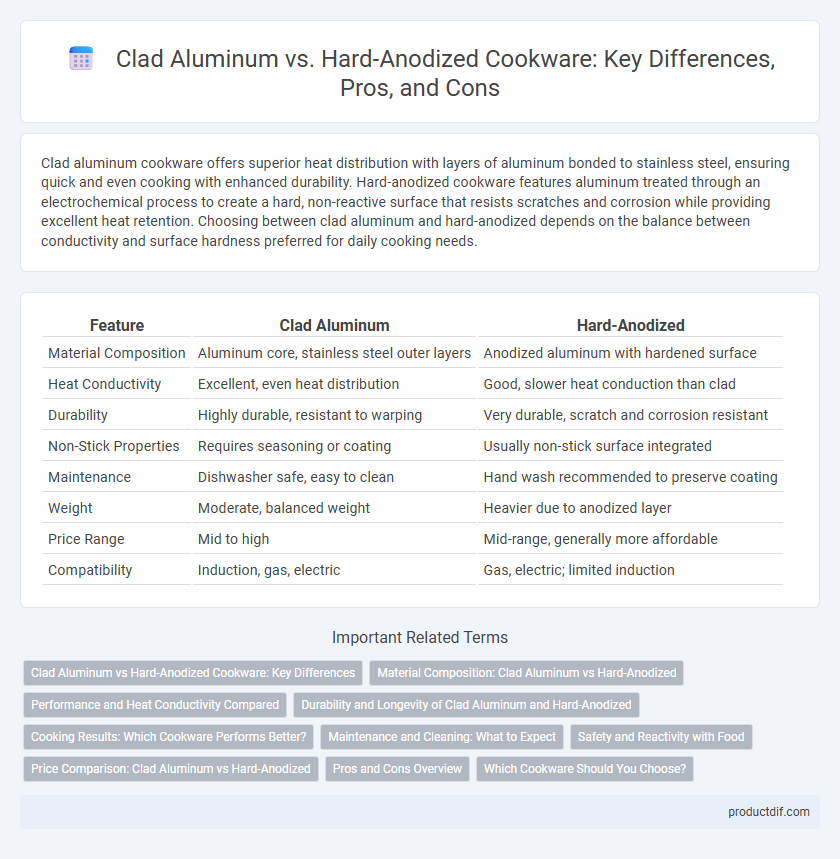

| Feature | Clad Aluminum | Hard-Anodized |

|---|---|---|

| Material Composition | Aluminum core, stainless steel outer layers | Anodized aluminum with hardened surface |

| Heat Conductivity | Excellent, even heat distribution | Good, slower heat conduction than clad |

| Durability | Highly durable, resistant to warping | Very durable, scratch and corrosion resistant |

| Non-Stick Properties | Requires seasoning or coating | Usually non-stick surface integrated |

| Maintenance | Dishwasher safe, easy to clean | Hand wash recommended to preserve coating |

| Weight | Moderate, balanced weight | Heavier due to anodized layer |

| Price Range | Mid to high | Mid-range, generally more affordable |

| Compatibility | Induction, gas, electric | Gas, electric; limited induction |

Clad Aluminum vs Hard-Anodized Cookware: Key Differences

Clad aluminum cookware features layers of aluminum and stainless steel that provide excellent heat conductivity and even cooking, while hard-anodized cookware is aluminum treated to create a durable, non-reactive surface resistant to corrosion and scratches. Clad aluminum excels in temperature control and heat distribution, making it ideal for precise cooking techniques, whereas hard-anodized pans are known for their durability and non-stick properties, suitable for everyday use and high-temperature cooking. Choosing between the two depends on priorities such as heat efficiency, durability, and maintenance preferences.

Material Composition: Clad Aluminum vs Hard-Anodized

Clad aluminum cookware features layers of aluminum bonded to stainless steel, providing superior heat conductivity and even cooking performance. Hard-anodized cookware is made from aluminum treated through an electrochemical process, resulting in a dense, non-reactive, and scratch-resistant surface. Clad aluminum excels in heat distribution due to its multi-layer construction, while hard-anodized emphasizes durability and resistance to corrosion and wear.

Performance and Heat Conductivity Compared

Clad aluminum cookware offers superior heat conductivity due to its layered construction, ensuring even heat distribution and minimizing hot spots during cooking. Hard-anodized cookware provides excellent durability and resistance to corrosion but has slightly lower thermal conductivity compared to clad aluminum. For precision cooking and uniform heat performance, clad aluminum is often preferred, while hard-anodized excels in longevity and non-stick surface durability.

Durability and Longevity of Clad Aluminum and Hard-Anodized

Clad aluminum cookware features layers of aluminum bonded with stainless steel, offering exceptional durability and resistance to warping, ensuring long-lasting performance. Hard-anodized cookware undergoes an electrochemical process that hardens the aluminum surface, making it highly scratch-resistant and corrosion-proof, which significantly extends its lifespan. Both materials provide superior longevity, but clad aluminum is often favored for even heat distribution and sustained structural integrity over years of use.

Cooking Results: Which Cookware Performs Better?

Clad aluminum cookware offers superior heat distribution and responsiveness, ensuring even cooking and precise temperature control, ideal for delicate sauces and searing. Hard-anodized cookware provides excellent durability and nonstick surfaces but may have slightly less efficient heat conduction, resulting in less uniform cooking. For optimal cooking results, clad aluminum generally outperforms hard-anodized in terms of performance and consistency.

Maintenance and Cleaning: What to Expect

Clad aluminum cookware requires gentle hand washing with mild detergent to maintain its non-reactive surface and avoid discoloration, whereas hard-anodized cookware offers superior resistance to scratches and staining, allowing for easier cleaning and less frequent maintenance. Hard-anodized pans are often dishwasher safe and can withstand abrasive scrubbing without damage, while clad aluminum typically demands more careful handling to prevent surface wear. Regular seasoning is unnecessary for both, but hard-anodized surfaces retain their smooth, nonstick qualities longer under routine kitchen use.

Safety and Reactivity with Food

Clad aluminum cookware features a layer of aluminum sandwiched between stainless steel, offering non-reactive cooking surfaces that ensure food flavor remains pure and safe from metallic contamination. Hard-anodized cookware undergoes an electrochemical process that creates a dense, non-porous surface highly resistant to corrosion and reactive agents, reducing the risk of aluminum leaching into food. Both materials provide safe cooking options, but clad aluminum's stainless steel exterior typically offers superior non-reactivity for acidic or alkaline ingredients.

Price Comparison: Clad Aluminum vs Hard-Anodized

Clad aluminum cookware typically commands a higher price due to its multi-layer construction and superior heat distribution properties, making it a popular choice for professional chefs. Hard-anodized cookware tends to be more affordable while still offering durability and non-stick surfaces, appealing to budget-conscious home cooks. Consumers often weigh the initial investment of clad aluminum against the cost-effectiveness and performance of hard-anodized options when selecting cookware.

Pros and Cons Overview

Clad aluminum cookware offers superior heat distribution and durability due to its multi-layered construction, making it ideal for precise temperature control, while its higher price point can be a drawback. Hard-anodized cookware resists scratches and corrosion effectively, providing a non-stick surface without chemical coatings, though it may heat less evenly and require careful maintenance to avoid damage. Choosing between clad aluminum and hard-anodized depends on priorities like heat performance, durability, and budget constraints.

Which Cookware Should You Choose?

Clad aluminum cookware offers superior heat conductivity and even cooking due to its layered construction, making it ideal for precision cooking and rapid temperature changes. Hard-anodized cookware features a durable, non-reactive surface resistant to scratches and corrosion, perfect for heavy use and high-heat searing. Choosing between clad aluminum and hard-anodized cookware depends on your cooking style: opt for clad aluminum for professional-level heat control and hard-anodized for long-lasting durability and stick resistance.

Clad Aluminum vs Hard-Anodized Infographic

productdif.com

productdif.com