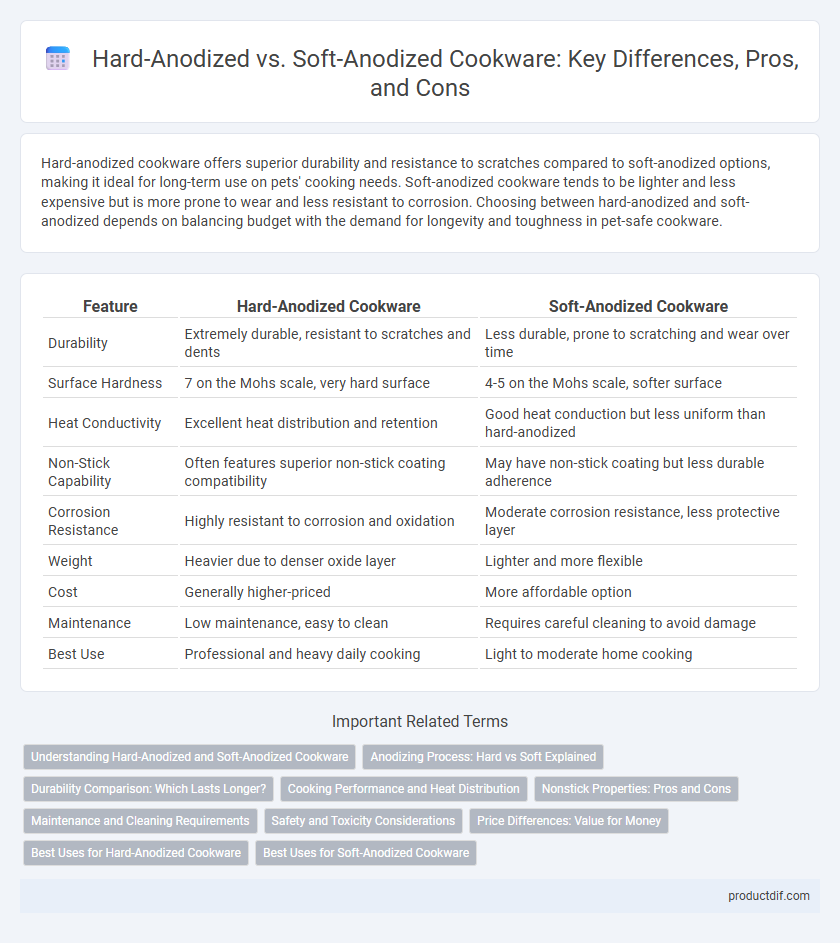

Hard-anodized cookware offers superior durability and resistance to scratches compared to soft-anodized options, making it ideal for long-term use on pets' cooking needs. Soft-anodized cookware tends to be lighter and less expensive but is more prone to wear and less resistant to corrosion. Choosing between hard-anodized and soft-anodized depends on balancing budget with the demand for longevity and toughness in pet-safe cookware.

Table of Comparison

| Feature | Hard-Anodized Cookware | Soft-Anodized Cookware |

|---|---|---|

| Durability | Extremely durable, resistant to scratches and dents | Less durable, prone to scratching and wear over time |

| Surface Hardness | 7 on the Mohs scale, very hard surface | 4-5 on the Mohs scale, softer surface |

| Heat Conductivity | Excellent heat distribution and retention | Good heat conduction but less uniform than hard-anodized |

| Non-Stick Capability | Often features superior non-stick coating compatibility | May have non-stick coating but less durable adherence |

| Corrosion Resistance | Highly resistant to corrosion and oxidation | Moderate corrosion resistance, less protective layer |

| Weight | Heavier due to denser oxide layer | Lighter and more flexible |

| Cost | Generally higher-priced | More affordable option |

| Maintenance | Low maintenance, easy to clean | Requires careful cleaning to avoid damage |

| Best Use | Professional and heavy daily cooking | Light to moderate home cooking |

Understanding Hard-Anodized and Soft-Anodized Cookware

Hard-anodized cookware features a dense, non-porous surface created through electrochemical treatment, offering exceptional durability, scratch resistance, and enhanced heat distribution. Soft-anodized cookware undergoes a milder anodizing process, resulting in a less hardened surface that retains some natural aluminum softness and is more prone to wear and corrosion. Both types provide improved corrosion resistance compared to untreated aluminum but differ significantly in longevity and maintenance requirements due to their structural differences.

Anodizing Process: Hard vs Soft Explained

The anodizing process for cookware involves electrolytic oxidation to create a durable, corrosion-resistant surface, with hard-anodized cookware undergoing longer, more intense treatment producing a denser, harder coating compared to soft-anodized variants. Hard anodizing results in a surface that is typically five times harder than stainless steel, offering superior scratch and wear resistance, while soft anodizing creates a thinner layer that enhances corrosion resistance but lacks the same durability. This difference in anodizing intensity directly affects cookware performance, heat conduction, and longevity in kitchen use.

Durability Comparison: Which Lasts Longer?

Hard-anodized cookware undergoes a more intensive electrochemical process, resulting in a denser, much harder surface that resists scratches, dents, and corrosion far better than soft-anodized cookware. Soft-anodized pans, while offering improved corrosion resistance compared to untreated aluminum, tend to be more prone to wear and damage over time due to their softer surface layer. Therefore, hard-anodized cookware generally lasts significantly longer, making it a preferred choice for durability and long-term kitchen use.

Cooking Performance and Heat Distribution

Hard-anodized cookware offers superior cooking performance due to its dense, non-porous surface that provides excellent heat retention and even heat distribution, minimizing hot spots for consistent cooking results. Soft-anodized cookware, while corrosion-resistant, typically has a less durable surface that can lead to uneven heating and reduced non-stick properties, impacting cooking efficiency. The enhanced thermal conductivity in hard-anodized pans makes them ideal for searing, sauteing, and dishes requiring precise temperature control.

Nonstick Properties: Pros and Cons

Hard-anodized cookware features a dense, durable surface that provides superior nonstick properties, reducing food sticking and enabling easy cleanup. Soft-anodized cookware offers a slightly less resilient coating, which may wear more quickly and require more frequent seasoning to maintain nonstick performance. The enhanced hardness of hard-anodized pans increases scratch resistance and longevity, making them a preferred choice for heavy-duty cooking and long-term use.

Maintenance and Cleaning Requirements

Hard-anodized cookware features a dense, non-porous surface that resists scratching and corrosion, requiring minimal maintenance and simple cleaning with mild detergents and non-abrasive sponges. Soft-anodized cookware, being less durable, demands more careful handling to prevent surface damage and often requires hand washing to preserve its finish. Both types benefit from avoiding metal utensils and abrasive cleaners to extend their lifespan and maintain optimal cooking performance.

Safety and Toxicity Considerations

Hard-anodized cookware offers a denser, non-reactive surface that enhances safety by preventing aluminum leaching, making it a preferred choice for toxic-free cooking. Soft-anodized cookware, while lighter, may have a less durable oxide layer that can expose the aluminum base over time, raising potential toxicity concerns with acidic foods. Choosing hard-anodized cookware ensures a safer, more inert cooking environment, reducing risks of harmful metal exposure.

Price Differences: Value for Money

Hard-anodized cookware typically costs 20-40% more than soft-anodized options due to its enhanced durability and resistance to scratches and corrosion. This price difference often translates into better value for money for frequent cooks seeking long-term investment in kitchen tools. Soft-anodized cookware, while cheaper, may wear out faster and require replacement sooner, affecting overall cost-effectiveness.

Best Uses for Hard-Anodized Cookware

Hard-anodized cookware offers superior durability and resistance to scratches, making it ideal for high-heat searing and frequent use in professional kitchens. Its non-reactive surface prevents food from interacting with the metal, ensuring safe cooking for acidic ingredients like tomatoes and citrus. The enhanced heat distribution of hard-anodized pans provides consistent cooking results, perfect for frying, sauteing, and browning.

Best Uses for Soft-Anodized Cookware

Soft-anodized cookware offers excellent heat conductivity and is ideal for low to medium-heat cooking tasks such as simmering sauces and sauteing vegetables. Its non-reactive surface makes it perfect for cooking acidic foods without altering flavors or causing discoloration. Lightweight and easy to handle, soft-anodized pans are best suited for everyday use and gentle cooking techniques.

Hard-Anodized vs Soft-Anodized Infographic

productdif.com

productdif.com