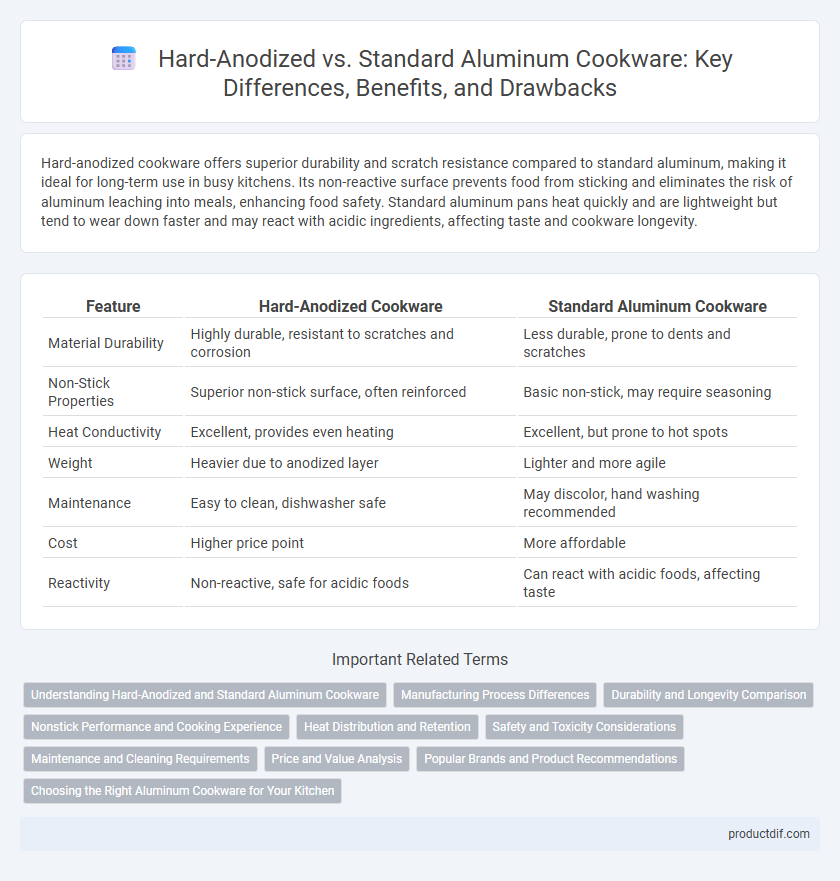

Hard-anodized cookware offers superior durability and scratch resistance compared to standard aluminum, making it ideal for long-term use in busy kitchens. Its non-reactive surface prevents food from sticking and eliminates the risk of aluminum leaching into meals, enhancing food safety. Standard aluminum pans heat quickly and are lightweight but tend to wear down faster and may react with acidic ingredients, affecting taste and cookware longevity.

Table of Comparison

| Feature | Hard-Anodized Cookware | Standard Aluminum Cookware |

|---|---|---|

| Material Durability | Highly durable, resistant to scratches and corrosion | Less durable, prone to dents and scratches |

| Non-Stick Properties | Superior non-stick surface, often reinforced | Basic non-stick, may require seasoning |

| Heat Conductivity | Excellent, provides even heating | Excellent, but prone to hot spots |

| Weight | Heavier due to anodized layer | Lighter and more agile |

| Maintenance | Easy to clean, dishwasher safe | May discolor, hand washing recommended |

| Cost | Higher price point | More affordable |

| Reactivity | Non-reactive, safe for acidic foods | Can react with acidic foods, affecting taste |

Understanding Hard-Anodized and Standard Aluminum Cookware

Hard-anodized cookware features aluminum that has undergone an electrochemical treatment to create a durable, non-reactive surface, making it resistant to scratches and corrosion compared to standard aluminum. Standard aluminum cookware, while lightweight and excellent for heat conduction, is softer and more prone to dents, scratches, and reactions with acidic foods. Understanding the differences in durability, surface hardness, and reactivity helps in selecting cookware that balances performance and maintenance requirements.

Manufacturing Process Differences

Hard-anodized cookware undergoes an electrochemical process that thickens the natural oxide layer on aluminum, creating a durable, non-reactive surface resistant to corrosion and scratching. Standard aluminum cookware involves a simpler manufacturing process with raw aluminum shaped and tempered, lacking the enhanced protective oxide layer. This difference in manufacturing results in hard-anodized cookware providing superior durability and heat distribution compared to standard aluminum cookware.

Durability and Longevity Comparison

Hard-anodized cookware offers superior durability compared to standard aluminum due to its dense, non-porous surface that resists scratches, corrosion, and warping. The anodization process creates a hard outer layer three to five times stronger than conventional aluminum, significantly extending the cookware's longevity. Standard aluminum, although lightweight and conductive, tends to wear down faster and is more prone to dents and surface degradation over time.

Nonstick Performance and Cooking Experience

Hard-anodized cookware offers superior nonstick performance compared to standard aluminum due to its dense, natural oxide layer that resists scratching and improves food release. This surface enhances cooking experience by providing even heat distribution and durability, reducing the need for excessive oil or butter. Standard aluminum, while lightweight and conductive, often requires synthetic coatings that may wear off faster, impacting long-term nonstick quality and ease of cleaning.

Heat Distribution and Retention

Hard-anodized cookware offers superior heat distribution due to its dense, non-porous surface that prevents hot spots and ensures even cooking. This material also excels in heat retention, maintaining consistent temperatures longer compared to standard aluminum, which cools quickly and heats unevenly. Choosing hard-anodized pots and pans enhances cooking precision and energy efficiency in the kitchen.

Safety and Toxicity Considerations

Hard-anodized cookware offers enhanced safety by creating a non-reactive, durable surface that resists scratches and prevents aluminum from leaching into food, unlike standard aluminum which can corrode and release trace amounts of aluminum with acidic or alkaline ingredients. The hard-anodizing process forms a dense oxide layer that is highly resistant to corrosion, reducing the risk of toxicity concerns linked to aluminum exposure. Choosing hard-anodized cookware helps minimize potential health risks associated with aluminum, making it a safer option for everyday cooking.

Maintenance and Cleaning Requirements

Hard-anodized cookware features a durable, non-porous surface that resists scratches and corrosion, making it easier to clean and maintain compared to standard aluminum. Standard aluminum cookware tends to oxidize and discolor over time, requiring regular seasoning or special cleaning agents to preserve its appearance and performance. Both types benefit from hand washing with mild detergents, but hard-anodized cookware is generally more resistant to staining and warping.

Price and Value Analysis

Hard-anodized cookware typically costs 20-40% more than standard aluminum due to its enhanced durability and non-reactive surface. While standard aluminum offers excellent heat conductivity at a lower price point, it is more prone to scratching and warping over time. The higher initial investment in hard-anodized pans provides better long-term value by reducing the need for frequent replacements.

Popular Brands and Product Recommendations

Hard-anodized cookware from popular brands like Calphalon and All-Clad offers superior durability and non-reactive surfaces compared to standard aluminum options from brands such as T-fal and Cuisinart. Products like Calphalon's hard-anodized fry pans ensure enhanced heat distribution and resistance to scratching, making them ideal for everyday cooking. Standard aluminum cookware is lightweight and affordable but may lack the longevity and premium performance found in hard-anodized alternatives.

Choosing the Right Aluminum Cookware for Your Kitchen

Hard-anodized aluminum cookware offers superior durability and non-reactive surfaces compared to standard aluminum, making it ideal for long-term use and high-temperature cooking. Standard aluminum cookware is lightweight and highly conductive but more susceptible to scratching and reacting with acidic foods. Choosing the right aluminum cookware depends on your cooking style, durability needs, and maintenance preferences to ensure optimal kitchen performance.

Hard-Anodized vs Standard Aluminum Infographic

productdif.com

productdif.com