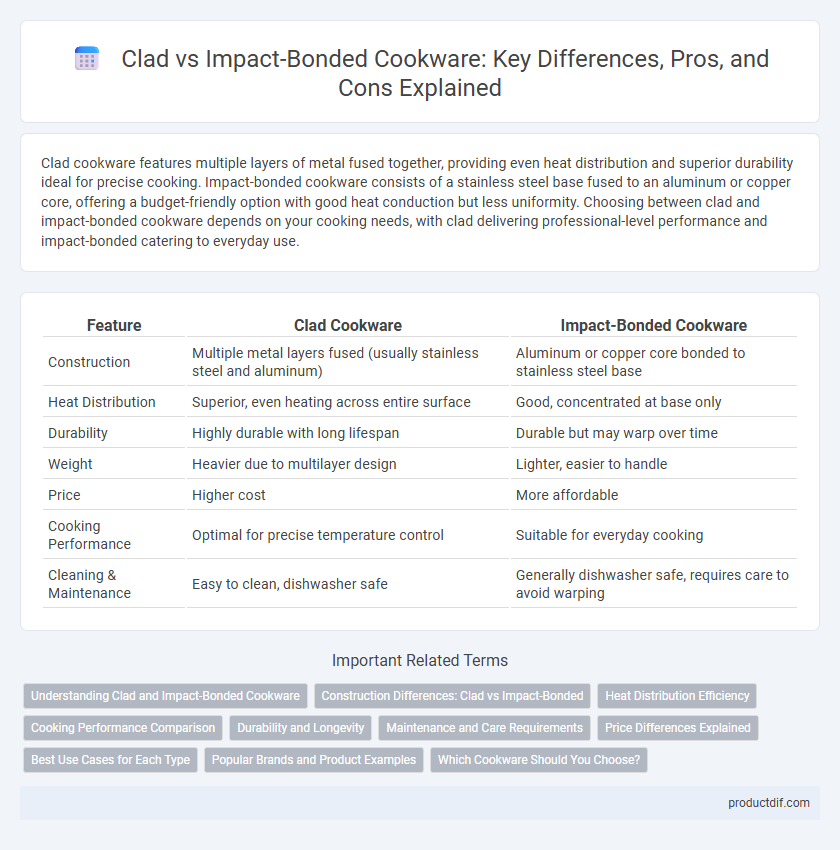

Clad cookware features multiple layers of metal fused together, providing even heat distribution and superior durability ideal for precise cooking. Impact-bonded cookware consists of a stainless steel base fused to an aluminum or copper core, offering a budget-friendly option with good heat conduction but less uniformity. Choosing between clad and impact-bonded cookware depends on your cooking needs, with clad delivering professional-level performance and impact-bonded catering to everyday use.

Table of Comparison

| Feature | Clad Cookware | Impact-Bonded Cookware |

|---|---|---|

| Construction | Multiple metal layers fused (usually stainless steel and aluminum) | Aluminum or copper core bonded to stainless steel base |

| Heat Distribution | Superior, even heating across entire surface | Good, concentrated at base only |

| Durability | Highly durable with long lifespan | Durable but may warp over time |

| Weight | Heavier due to multilayer design | Lighter, easier to handle |

| Price | Higher cost | More affordable |

| Cooking Performance | Optimal for precise temperature control | Suitable for everyday cooking |

| Cleaning & Maintenance | Easy to clean, dishwasher safe | Generally dishwasher safe, requires care to avoid warping |

Understanding Clad and Impact-Bonded Cookware

Clad cookware features multiple layers of metal, typically stainless steel bonded directly to aluminum or copper, ensuring even heat distribution and durability. Impact-bonded cookware has a single metal base, usually aluminum or copper, fused under high pressure to a stainless steel exterior, which improves heat conduction but may cause uneven heating. Understanding the construction differences helps in choosing cookware that balances heat performance, weight, and maintenance based on cooking needs.

Construction Differences: Clad vs Impact-Bonded

Clad cookware features multiple layers of metal, often stainless steel bonded with an aluminum or copper core throughout the entire cooking surface for even heat distribution. Impact-bonded cookware consists of a single stainless steel layer with a thick aluminum disc bonded only to the base to improve heat conduction. This construction difference affects heat retention, durability, and responsiveness during cooking.

Heat Distribution Efficiency

Clad cookware features multiple layers of metal, typically stainless steel and aluminum or copper, bonded throughout the entire cooking surface, resulting in superior heat distribution and consistent cooking performance. Impact-bonded cookware has a single aluminum or copper disk bonded to the base, which concentrates heat more at the center and creates uneven temperature distribution across the pan. The comprehensive layering in clad cookware enables quick, efficient heat transfer and minimizes hot spots, making it ideal for precise control during cooking.

Cooking Performance Comparison

Clad cookware offers superior heat distribution and retention due to its multiple layers of metal, typically combining stainless steel with an aluminum or copper core, which ensures even cooking and minimizes hot spots. In contrast, impact-bonded cookware features a single layer of stainless steel fused to an aluminum base, resulting in less consistent heat conduction and slower response to temperature changes. Chefs often prefer clad cookware for precision cooking and versatility, while impact-bonded sets are valued for budget-friendly, durable options with moderate performance.

Durability and Longevity

Clad cookware features multiple layers of metal, typically stainless steel and aluminum, fused together, providing superior durability and even heat distribution that prevents warping over time. Impact-bonded cookware consists of a single stainless steel base bonded to an aluminum core, which may be less durable as the bond can weaken with heavy use and exposure to high heat. Clad cookware generally offers greater longevity due to its robust construction and resistance to corrosion, making it a preferred choice for professional chefs and serious home cooks.

Maintenance and Care Requirements

Clad cookware, constructed with multiple bonded metal layers such as stainless steel and aluminum, requires careful hand washing and gentle scouring to maintain its smooth, non-reactive surface and prevent damage to the metal layers. Impact-bonded cookware features a thick aluminum or copper base bonded to stainless steel surfaces, offering greater durability that allows some models to be dishwasher-safe, though hand washing is still preferred to preserve the cookware's longevity. Both types benefit from avoiding abrasive cleaners and metal utensils to sustain optimal heat distribution and prevent warping or surface degradation over time.

Price Differences Explained

Clad cookware, featuring layers of stainless steel and aluminum permanently bonded through high heat and pressure, generally commands higher prices due to its superior heat conductivity, durability, and even cooking performance. Impact-bonded cookware, where an aluminum or copper disc is mechanically attached to the base of a stainless steel pan, tends to be more affordable but may offer less consistent heat distribution and durability over time. The price gap reflects differences in manufacturing processes, material integration, and overall cooking efficiency.

Best Use Cases for Each Type

Clad cookware features layers of metal bonded throughout the entire pan, providing even heat distribution ideal for precise cooking techniques like sauteing, searing, and simmering. Impact-bonded cookware has a metal disk fused to the bottom, offering quick heat responsiveness that suits high-heat tasks such as frying or boiling. For professional-quality cooking and temperature control, clad cookware excels, while impact-bonded cookware is best for budget-conscious cooks needing fast heat on stovetops.

Popular Brands and Product Examples

All-Clad is a leading brand renowned for its high-quality clad cookware, featuring stainless steel layers bonded together for superior heat distribution and durability; popular products include the All-Clad D3 Stainless Steel and D5 Brushed Stainless Steel collections. In contrast, impact-bonded cookware often comes from brands like Cuisinart and T-fal, which use a single stainless steel base permanently fused to an aluminum core to provide responsive heating in budget-friendly lines such as the Cuisinart Multiclad Pro and T-fal Ultimate Hard Anodized. Both types cater to different cooking needs, with All-Clad's clad cookware favored by professional chefs and impact-bonded options popular among everyday home cooks seeking value and performance.

Which Cookware Should You Choose?

Clad cookware offers superior heat distribution and durability due to its multiple layers of metal bonded throughout the entire vessel, making it ideal for precise cooking tasks and long-term use. Impact-bonded cookware features a single stainless steel layer bonded to an aluminum or copper base, providing good heat conductivity at a lower cost but often with less even heat. Choose clad cookware for professional-quality performance and longevity, while impact-bonded cookware suits budget-conscious cooks seeking reliable everyday use.

Clad Cookware vs Impact-Bonded Cookware Infographic

productdif.com

productdif.com