Anodized aluminum cookware offers lightweight durability and excellent heat conduction, making it ideal for quick, even cooking. Cast iron provides superior heat retention and natural nonstick properties when properly seasoned, perfect for slow-cooked meals and high-heat searing. Choosing between them depends on your cooking style, with anodized aluminum favoring speed and ease, while cast iron excels in versatility and longevity.

Table of Comparison

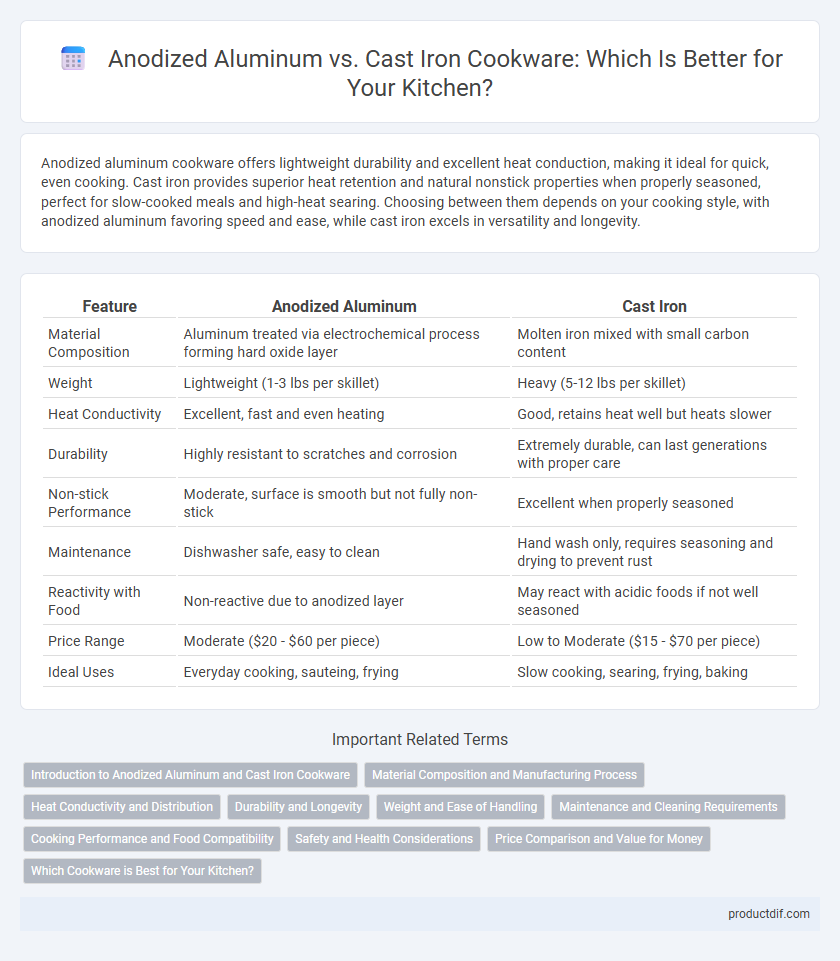

| Feature | Anodized Aluminum | Cast Iron |

|---|---|---|

| Material Composition | Aluminum treated via electrochemical process forming hard oxide layer | Molten iron mixed with small carbon content |

| Weight | Lightweight (1-3 lbs per skillet) | Heavy (5-12 lbs per skillet) |

| Heat Conductivity | Excellent, fast and even heating | Good, retains heat well but heats slower |

| Durability | Highly resistant to scratches and corrosion | Extremely durable, can last generations with proper care |

| Non-stick Performance | Moderate, surface is smooth but not fully non-stick | Excellent when properly seasoned |

| Maintenance | Dishwasher safe, easy to clean | Hand wash only, requires seasoning and drying to prevent rust |

| Reactivity with Food | Non-reactive due to anodized layer | May react with acidic foods if not well seasoned |

| Price Range | Moderate ($20 - $60 per piece) | Low to Moderate ($15 - $70 per piece) |

| Ideal Uses | Everyday cooking, sauteing, frying | Slow cooking, searing, frying, baking |

Introduction to Anodized Aluminum and Cast Iron Cookware

Anodized aluminum cookware features a durable, non-reactive surface created through an electrochemical process that enhances corrosion resistance and heat distribution. Cast iron cookware is renowned for its excellent heat retention, naturally non-stick characteristics after seasoning, and durability that improves with use over time. Both materials offer distinct cooking benefits, with anodized aluminum excelling in lightweight design and even heating, while cast iron provides superior heat retention and versatility for high-temperature cooking.

Material Composition and Manufacturing Process

Anodized aluminum cookware features a base of aluminum metal treated through an electrochemical process that thickens the natural oxide layer, enhancing durability, corrosion resistance, and non-reactivity. Cast iron cookware is made by pouring molten iron mixed with carbon into molds, creating a dense, heat-retentive material prized for its even heat distribution and natural non-stick seasoning over time. The anodization process offers lightweight, low-maintenance cookware, while cast iron demands seasoning but provides superior heat retention and long-term durability.

Heat Conductivity and Distribution

Anodized aluminum cookware offers superior heat conductivity, rapidly and evenly distributing heat across the cooking surface for precise temperature control. Cast iron, while slower to heat, excels in heat retention and provides consistent, uniform cooking once heated. Choosing between anodized aluminum and cast iron depends on the need for quick, even heat versus deep, lasting heat for searing and slow cooking.

Durability and Longevity

Anodized aluminum cookware offers exceptional durability with a hard, non-reactive surface that resists scratches, corrosion, and warping, ensuring long-lasting performance. Cast iron excels in longevity due to its robust construction and ability to develop a natural non-stick seasoning over time, often lasting generations with proper care. While anodized aluminum is lightweight and low-maintenance, cast iron requires regular seasoning but provides unparalleled resilience against wear and high heat.

Weight and Ease of Handling

Anodized aluminum cookware is significantly lighter than cast iron, making it easier to handle and maneuver during cooking. Its smooth, non-porous surface also offers effortless cleaning and maintenance compared to the heavier, more cumbersome cast iron. For those prioritizing lightweight and ease of use, anodized aluminum provides a practical and efficient alternative to traditional cast iron cookware.

Maintenance and Cleaning Requirements

Anodized aluminum cookware requires minimal maintenance due to its non-porous, corrosion-resistant surface that resists staining and does not require seasoning, making cleaning simple with mild detergent and soft sponges. Cast iron demands regular seasoning to maintain its non-stick properties and prevent rust, necessitating thorough drying and oiling after each use, with cleaning typically done using coarse salt or brush instead of soap to preserve the seasoning layer. While anodized aluminum offers low-maintenance convenience, cast iron provides durability and heat retention at the cost of more intensive upkeep.

Cooking Performance and Food Compatibility

Anodized aluminum offers superior heat conductivity and rapid, even cooking, making it ideal for precise temperature control and delicate foods, while its non-reactive surface prevents metallic taste transfer. Cast iron provides exceptional heat retention and durability, enhancing searing and browning, but requires seasoning to maintain a natural non-stick layer and avoid rust. Both materials support diverse cooking techniques, with anodized aluminum excelling in low-acid to neutral dishes and cast iron best suited for high-heat applications and foods benefiting from seasoning.

Safety and Health Considerations

Anodized aluminum cookware features a non-reactive, hard surface that prevents aluminum leaching, making it a safer option for acidic foods compared to raw aluminum. Cast iron cookware is prized for its natural non-toxic qualities and ability to leach small amounts of iron, which can be beneficial for those with iron deficiencies but may pose risks for individuals with hemochromatosis. Both materials require proper maintenance to avoid rust in cast iron and surface degradation in anodized aluminum, ensuring safety and durability in cooking.

Price Comparison and Value for Money

Anodized aluminum cookware generally costs less upfront than cast iron, with prices ranging from $20 to $100 for quality pieces, compared to cast iron pans typically priced between $30 and $150. While anodized aluminum offers excellent non-stick properties and lightweight convenience, cast iron provides superior heat retention and durability, often improving with age, making it a long-term investment. For value-conscious buyers seeking longevity and versatile cooking performance, cast iron delivers better cost-effectiveness despite the higher initial price.

Which Cookware is Best for Your Kitchen?

Anodized aluminum cookware offers excellent heat conductivity, lightweight design, and resistance to corrosion, making it ideal for precise cooking and easy handling. Cast iron cookware excels in heat retention, durability, and versatility, providing superior searing and oven-to-table functionality, but requires maintenance to prevent rust. Choosing between anodized aluminum and cast iron depends on your cooking style, ease of use preferences, and care commitment in the kitchen.

Anodized Aluminum vs Cast Iron Infographic

productdif.com

productdif.com