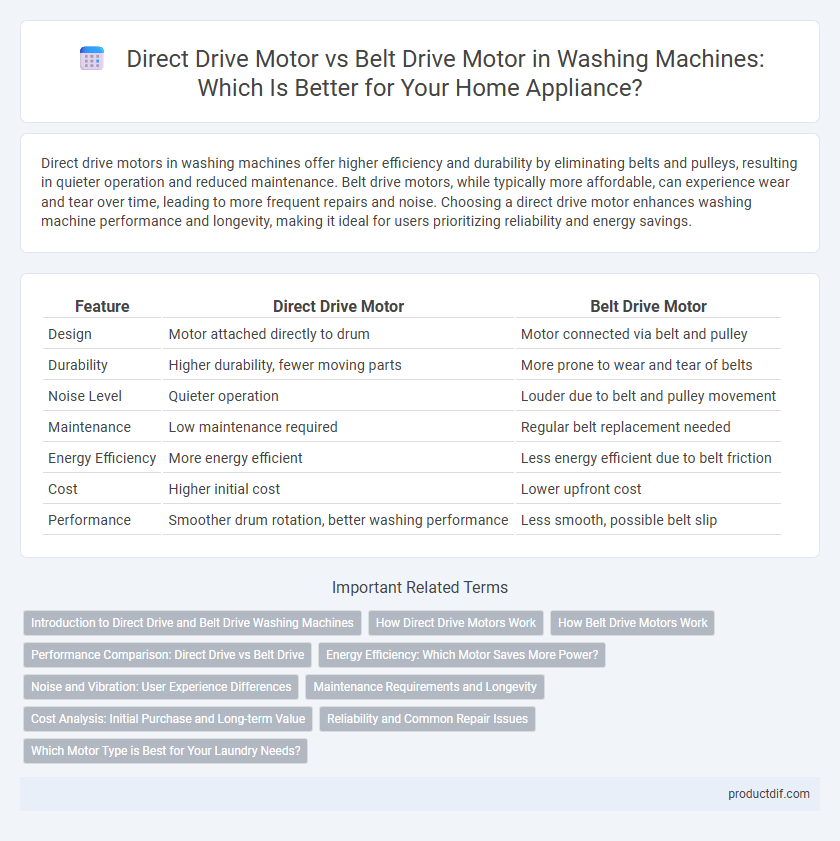

Direct drive motors in washing machines offer higher efficiency and durability by eliminating belts and pulleys, resulting in quieter operation and reduced maintenance. Belt drive motors, while typically more affordable, can experience wear and tear over time, leading to more frequent repairs and noise. Choosing a direct drive motor enhances washing machine performance and longevity, making it ideal for users prioritizing reliability and energy savings.

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Design | Motor attached directly to drum | Motor connected via belt and pulley |

| Durability | Higher durability, fewer moving parts | More prone to wear and tear of belts |

| Noise Level | Quieter operation | Louder due to belt and pulley movement |

| Maintenance | Low maintenance required | Regular belt replacement needed |

| Energy Efficiency | More energy efficient | Less energy efficient due to belt friction |

| Cost | Higher initial cost | Lower upfront cost |

| Performance | Smoother drum rotation, better washing performance | Less smooth, possible belt slip |

Introduction to Direct Drive and Belt Drive Washing Machines

Direct drive washing machines feature a motor directly attached to the drum, reducing mechanical parts and enhancing energy efficiency. Belt drive washing machines use a belt and pulley system to transfer power from the motor to the drum, resulting in more components that may require maintenance. Direct drive systems typically offer quieter operation and increased durability compared to belt drive motors.

How Direct Drive Motors Work

Direct drive motors in washing machines operate by attaching the motor directly to the drum, eliminating the need for belts or pulleys. This design enhances efficiency by reducing drivetrain losses and noise, leading to smoother and quieter operation. The precise control of rotational speed and torque in direct drive motors improves washing performance and extends appliance durability.

How Belt Drive Motors Work

Belt drive motors in washing machines operate by using a rubber belt to connect the motor to the drum, transferring rotational force efficiently. This design allows for smoother and quieter operation by absorbing vibrations between the motor and drum. Belt drive systems require periodic maintenance, such as belt replacement or adjustment, to ensure optimal performance and prevent slippage.

Performance Comparison: Direct Drive vs Belt Drive

Direct drive motors in washing machines offer higher efficiency and quieter operation compared to belt drive motors, as they eliminate the energy loss and wear associated with belts. The direct attachment of the motor to the drum results in improved durability and faster spin cycles, enhancing overall washing performance. Belt drive motors, while generally less expensive, require more maintenance due to belt wear and can deliver less consistent power, affecting wash quality and energy consumption.

Energy Efficiency: Which Motor Saves More Power?

Direct drive motors in washing machines eliminate the need for belts and pulleys, reducing energy loss and increasing overall efficiency by up to 30% compared to traditional belt drive motors. Belt drive motors often experience friction and slippage, causing higher energy consumption during operation. The reduced mechanical complexity of direct drive systems translates to lower electricity bills and a smaller environmental footprint.

Noise and Vibration: User Experience Differences

Direct drive motors in washing machines reduce noise and vibration significantly compared to belt drive motors, enhancing user comfort during operation. Belt drive motors typically generate more mechanical noise and vibrations due to belt friction and wear over time. The quieter and smoother performance of direct drive motors leads to better overall user satisfaction and less disturbance in household environments.

Maintenance Requirements and Longevity

Direct drive motors in washing machines require less maintenance due to fewer moving parts and the absence of belts, which reduces wear and tear. Belt drive motors typically need regular belt inspections and replacements to prevent breakdowns, increasing maintenance efforts. Direct drive designs generally offer longer longevity and enhanced durability compared to belt drive systems, contributing to improved appliance lifespan.

Cost Analysis: Initial Purchase and Long-term Value

Direct drive motors in washing machines often have a higher initial purchase price compared to belt drive motors due to advanced technology and fewer moving parts. Over time, direct drive motors generally offer better long-term value by reducing maintenance costs and improving energy efficiency. Belt drive motors may require more frequent repairs and belt replacements, increasing overall ownership expenses despite their lower upfront cost.

Reliability and Common Repair Issues

Direct drive motors in washing machines offer higher reliability due to fewer moving parts, reducing wear and tear compared to belt drive motors. Belt drive motors often face common repair issues such as belt slippage, stretching, or breakage, which can cause operational failures. Direct drive systems also minimize maintenance needs and typically have longer lifespans, enhancing overall appliance durability.

Which Motor Type is Best for Your Laundry Needs?

Direct drive motors in washing machines offer higher energy efficiency, reduced noise levels, and longer durability due to fewer moving parts compared to belt drive motors. Belt drive motors, while often more affordable and easier to repair, tend to generate more noise and require regular maintenance as belts can wear out or slip over time. Choosing the best motor depends on your priority for quiet operation, energy savings, and low maintenance versus upfront cost and ease of repair.

Direct drive motor vs Belt drive motor (washing machine) Infographic

productdif.com

productdif.com