Surface printing offers vibrant, textured patterns ideal for creating tactile wall coverings that add depth and character. Digital printing excels in precision and customization, enabling intricate designs and rapid production with a wider color spectrum. Choosing between surface printing and digital printing depends on desired texture, detail level, and production scale for pet-friendly wall coverings.

Table of Comparison

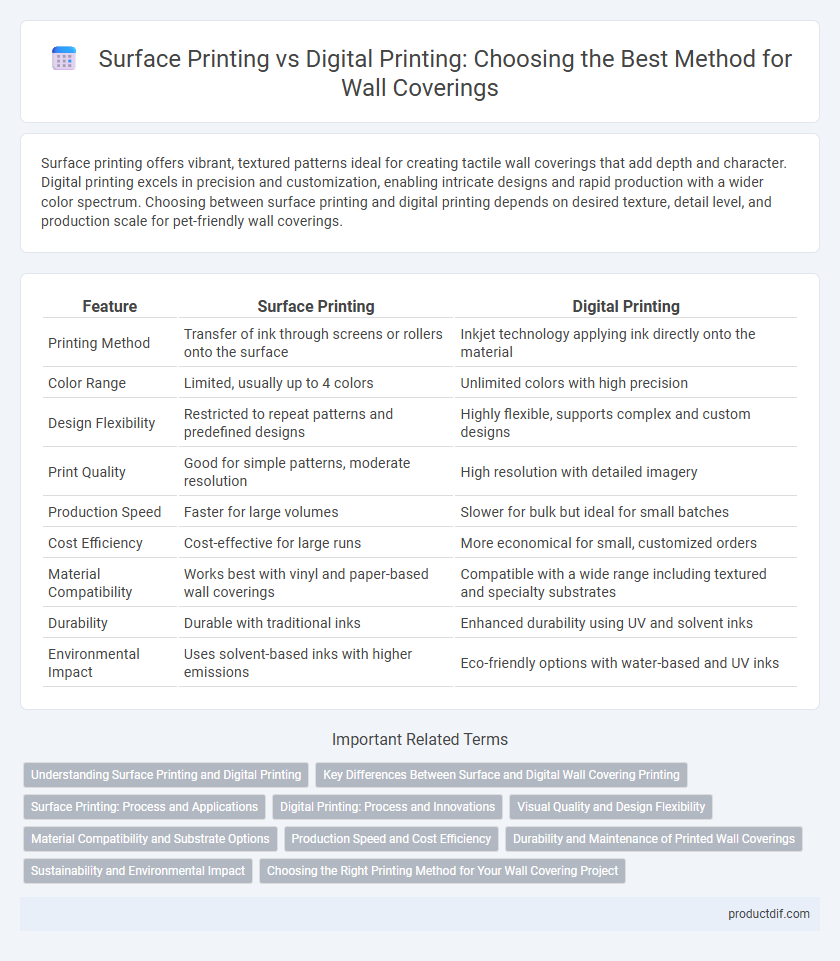

| Feature | Surface Printing | Digital Printing |

|---|---|---|

| Printing Method | Transfer of ink through screens or rollers onto the surface | Inkjet technology applying ink directly onto the material |

| Color Range | Limited, usually up to 4 colors | Unlimited colors with high precision |

| Design Flexibility | Restricted to repeat patterns and predefined designs | Highly flexible, supports complex and custom designs |

| Print Quality | Good for simple patterns, moderate resolution | High resolution with detailed imagery |

| Production Speed | Faster for large volumes | Slower for bulk but ideal for small batches |

| Cost Efficiency | Cost-effective for large runs | More economical for small, customized orders |

| Material Compatibility | Works best with vinyl and paper-based wall coverings | Compatible with a wide range including textured and specialty substrates |

| Durability | Durable with traditional inks | Enhanced durability using UV and solvent inks |

| Environmental Impact | Uses solvent-based inks with higher emissions | Eco-friendly options with water-based and UV inks |

Understanding Surface Printing and Digital Printing

Surface printing involves applying ink directly onto textured or uneven wallpaper surfaces using engraved rollers, creating vibrant and tactile patterns ideal for traditional designs. Digital printing employs high-resolution inkjet technology to reproduce intricate, full-color images on smooth wallpaper substrates with exceptional detail and customization options. Compared to surface printing, digital printing offers faster production, greater design flexibility, and the ability to produce short runs without compromising quality.

Key Differences Between Surface and Digital Wall Covering Printing

Surface printing on wall coverings relies on traditional roller or screen techniques that apply ink layer by layer, offering rich texture and vibrant colors but limited design complexity. Digital printing utilizes inkjet technology to produce highly detailed, customizable patterns with a broader color range and faster turnaround, ideal for intricate and small-batch designs. Key differences include production speed, color variation, texture depth, and flexibility in design customization, with digital printing leading in precision and versatility.

Surface Printing: Process and Applications

Surface printing involves transferring ink directly onto textured or flat wall coverings using engraved rollers, creating rich, tactile patterns ideal for traditional and classic designs. This process excels in producing high-quality, consistent motifs on vinyl, fabric, and paper substrates, making it popular for wallpapers, murals, and decorative panels. Its ability to apply thick coatings and metallic inks enhances durability and visual depth, suitable for both residential and commercial interior spaces.

Digital Printing: Process and Innovations

Digital printing in wall coverings employs advanced inkjet technology to apply high-resolution designs directly onto surfaces, ensuring vibrant colors and intricate details. Innovations such as UV curing and eco-friendly inks enhance durability, reduce production time, and minimize environmental impact. This process allows for seamless customization, rapid prototyping, and cost-effective short runs compared to traditional surface printing methods.

Visual Quality and Design Flexibility

Surface printing offers vibrant colors and sharp details but is limited by traditional patterns and repeat designs, whereas digital printing delivers unparalleled design flexibility, allowing for limitless customization and intricate visuals. Digital printing excels in producing high-resolution images with gradient effects and photorealistic quality, enhancing the visual appeal of wall coverings. While surface printing maintains strong color saturation on textured surfaces, digital techniques provide superior accuracy and detail on smooth substrates, making each method suitable for different design requirements.

Material Compatibility and Substrate Options

Surface printing suits a wide range of traditional substrates such as vinyl, paper, and fabric, offering reliable adhesion and vivid colors on smooth, uniform surfaces. Digital printing excels in compatibility with diverse materials including textured wall coverings, nonwoven substrates, and specialty surfaces, enabling detailed designs and quick customization without compromising print quality. Material selection impacts durability and color vibrancy, with digital printing providing greater flexibility for complex materials compared to the more limited substrate options of surface printing.

Production Speed and Cost Efficiency

Surface printing offers faster production speeds for large, repetitive wall covering orders due to its mechanized process, reducing turnaround time significantly. Digital printing, while slower, provides greater cost efficiency for small batches and customized designs by eliminating setup expenses and minimizing material waste. Choosing between these methods depends largely on the scale and complexity of the project, with surface printing excelling in high-volume runs and digital printing optimized for bespoke or limited editions.

Durability and Maintenance of Printed Wall Coverings

Surface printing on wall coverings typically offers high durability due to its textured inks that embed deeply into the material, making it resistant to scratches and fading over time. Digital printing produces vibrant, detailed designs but may require protective coatings to enhance longevity and prevent damage from moisture or UV exposure. Maintenance for surface-printed walls often involves simple dusting and gentle cleaning, whereas digitally printed walls may need specialized cleaning solutions to preserve color integrity and prevent surface deterioration.

Sustainability and Environmental Impact

Surface printing uses traditional roller or rotary press techniques that consume more water, energy, and chemical inks, resulting in higher environmental impact compared to digital printing. Digital printing significantly reduces waste by applying ink directly onto wall coverings with precision, often using eco-friendly, water-based inks that lower VOC emissions and improve sustainability. Choosing digital printing advances sustainable wall covering production by minimizing resource consumption and promoting environmentally responsible manufacturing.

Choosing the Right Printing Method for Your Wall Covering Project

Surface printing offers vibrant colors and textures ideal for traditional and repetitive patterns, making it suitable for classic wallpaper designs. Digital printing provides high-resolution, customizable images with quick turnaround, perfect for intricate, photo-realistic, or small-batch wall coverings. Selecting between these methods depends on budget, design complexity, project scale, and desired finish, ensuring optimal aesthetic and practical results for your wall covering project.

Surface Printing vs Digital Printing Infographic

productdif.com

productdif.com