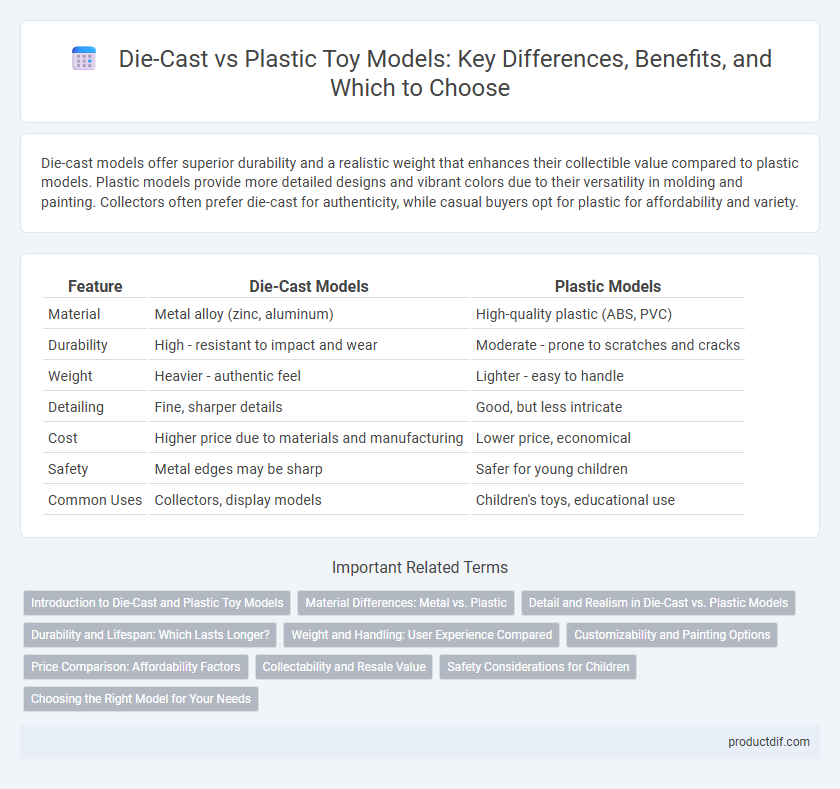

Die-cast models offer superior durability and a realistic weight that enhances their collectible value compared to plastic models. Plastic models provide more detailed designs and vibrant colors due to their versatility in molding and painting. Collectors often prefer die-cast for authenticity, while casual buyers opt for plastic for affordability and variety.

Table of Comparison

| Feature | Die-Cast Models | Plastic Models |

|---|---|---|

| Material | Metal alloy (zinc, aluminum) | High-quality plastic (ABS, PVC) |

| Durability | High - resistant to impact and wear | Moderate - prone to scratches and cracks |

| Weight | Heavier - authentic feel | Lighter - easy to handle |

| Detailing | Fine, sharper details | Good, but less intricate |

| Cost | Higher price due to materials and manufacturing | Lower price, economical |

| Safety | Metal edges may be sharp | Safer for young children |

| Common Uses | Collectors, display models | Children's toys, educational use |

Introduction to Die-Cast and Plastic Toy Models

Die-cast models are crafted from metal alloys, typically zinc or aluminum, providing durability and a premium weight that collectors value. Plastic toy models are made from injection-molded polymers, offering detailed designs at a lower cost and lighter weight for easier play. Each material influences the model's realism, longevity, and price, determining suitability for collectors versus children's toys.

Material Differences: Metal vs. Plastic

Die-cast models are primarily made from metal alloys such as zinc, aluminum, or magnesium, offering greater durability, weight, and a more realistic feel compared to plastic models. Plastic models use injection-molded plastics like ABS or polystyrene, which allow for intricate details and vibrant colors but tend to be lighter and less sturdy. The choice between metal and plastic materials significantly affects the model's longevity, texture, and overall collector value.

Detail and Realism in Die-Cast vs. Plastic Models

Die-cast models exhibit superior detail and realism compared to plastic models due to their metal construction, which allows for finer embossing and more accurate reproductions of textures and features. The weight and finish of die-cast materials contribute to a more authentic look and feel, enhancing the overall display quality. Plastic models often lack the intricate detail and durability found in die-cast counterparts, making them less appealing for collectors seeking high realism.

Durability and Lifespan: Which Lasts Longer?

Die-cast models typically offer superior durability and a longer lifespan compared to plastic models due to their metal construction, which resists wear and tear more effectively. Plastic models are more prone to scratches, cracks, and color fading over time, especially with frequent handling or exposure to sunlight. Collectors often prefer die-cast models for their robustness and ability to maintain value over years of use.

Weight and Handling: User Experience Compared

Die-cast models are significantly heavier than plastic models, offering a more solid and realistic feel that enhances user handling and durability. The increased weight provides better stability during play or display, while plastic models prioritize lighter, easier maneuverability but may sacrifice robustness. Users often prefer die-cast for its premium tactile experience and weighty authenticity, whereas plastic models appeal to those seeking ease of use and portability.

Customizability and Painting Options

Die-cast models offer limited customizability due to their rigid metal construction, making detailed painting and modification challenging compared to plastic models. Plastic models provide greater flexibility for customization with easier surface sanding, painting, and part swapping, allowing hobbyists to achieve intricate designs and personalized finishes. Enthusiasts seeking detailed custom paint jobs and structural alterations often prefer plastic models for enhanced creative control and versatility.

Price Comparison: Affordability Factors

Die-cast models generally have higher production costs due to metal materials and complex casting processes, resulting in a higher price point compared to plastic models. Plastic models benefit from cheaper raw materials and mass production techniques, making them more affordable for most consumers. Collectors often value die-cast models for durability and detail, justifying the premium price despite plastic alternatives being more budget-friendly.

Collectability and Resale Value

Die-cast models typically hold higher collectability and resale value due to their durability, intricate detailing, and limited production runs, attracting serious collectors. Plastic models, while often more affordable and easier to customize, generally depreciate faster and are less sought after in secondary markets. Collectors prioritize die-cast models for investment potential and long-term preservation.

Safety Considerations for Children

Die-cast models offer enhanced durability and resistance to breakage, reducing the risk of small parts detaching and posing choking hazards for children. Plastic models, while lightweight and often more flexible, can contain softer materials that may wear down, creating sharp edges or small fragments. Ensuring toys comply with safety standards such as ASTM F963 or EN71 is crucial regardless of material, as these regulations limit toxic substances and enforce mechanical safety to protect young users.

Choosing the Right Model for Your Needs

Die-cast models offer superior durability and detailed craftsmanship, making them ideal for collectors seeking authenticity and long-lasting display pieces. Plastic models provide versatility and ease of customization, appealing to hobbyists interested in painting and modifications. Understanding your priorities for display quality versus creative flexibility ensures choosing the right model aligns with your collecting goals and budget.

Die-cast models vs plastic models Infographic

productdif.com

productdif.com