Slip-joint drains offer easy installation and removal with their adjustable, threaded connections, making them ideal for repairs or modifications. In contrast, solvent-weld drains provide a permanent, leak-proof seal by chemically fusing pipes, ensuring durability and stability in plumbing fixtures. Choosing between slip-joint and solvent-weld drains depends on whether flexibility or long-term reliability is the priority in a plumbing setup.

Table of Comparison

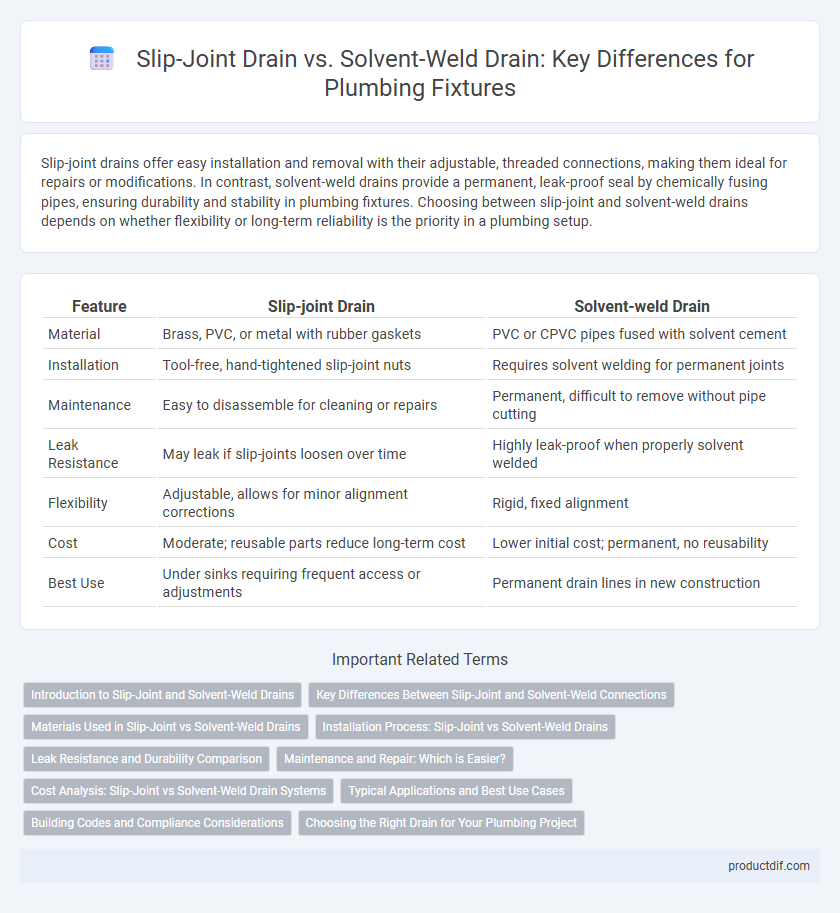

| Feature | Slip-joint Drain | Solvent-weld Drain |

|---|---|---|

| Material | Brass, PVC, or metal with rubber gaskets | PVC or CPVC pipes fused with solvent cement |

| Installation | Tool-free, hand-tightened slip-joint nuts | Requires solvent welding for permanent joints |

| Maintenance | Easy to disassemble for cleaning or repairs | Permanent, difficult to remove without pipe cutting |

| Leak Resistance | May leak if slip-joints loosen over time | Highly leak-proof when properly solvent welded |

| Flexibility | Adjustable, allows for minor alignment corrections | Rigid, fixed alignment |

| Cost | Moderate; reusable parts reduce long-term cost | Lower initial cost; permanent, no reusability |

| Best Use | Under sinks requiring frequent access or adjustments | Permanent drain lines in new construction |

Introduction to Slip-Joint and Solvent-Weld Drains

Slip-joint drains consist of threaded, adjustable joints that allow for easy assembly and disassembly without specialized tools, making them ideal for repair and maintenance in residential plumbing. Solvent-weld drains use a chemical solvent to fuse PVC pipes and fittings into a permanent, leak-proof connection commonly found in new construction and long-term installations. Understanding the distinct installation methods and applications of slip-joint versus solvent-weld drains helps optimize durability and flexibility in plumbing systems.

Key Differences Between Slip-Joint and Solvent-Weld Connections

Slip-joint drains utilize a compression fitting with a slip nut and washer, allowing for easy dismantling and adjustments, making them ideal for repairs and modifications. Solvent-weld drains rely on chemically fused PVC or ABS pipes that create a permanent, leak-proof bond, offering superior durability and resistance to pressure. The primary difference lies in slip-joint's flexibility versus solvent-weld's permanence, where slip-joint provides convenience and solvent-weld ensures a long-lasting, maintenance-free connection.

Materials Used in Slip-Joint vs Solvent-Weld Drains

Slip-joint drains typically use materials like brass, chrome-plated metal, or durable PVC, allowing for flexible connections and easy disassembly. Solvent-weld drains are predominantly made from rigid PVC or ABS plastic, relying on chemical adhesives that create permanent, watertight seals. The material choice impacts installation methods, with slip-joint components favoring mechanical fittings and solvent-weld drains requiring specialized solvent cement for durability.

Installation Process: Slip-Joint vs Solvent-Weld Drains

Slip-joint drains offer a flexible installation process with hand-tightened nuts and washers that allow for easy adjustments and disassembly, making them ideal for DIY projects or temporary setups. Solvent-weld drains require a precise, permanent bond formed by applying PVC or ABS solvent cement to the pipe and fitting, which demands careful alignment and curing time for a leak-proof seal. Choosing between slip-joint and solvent-weld drains depends on the need for ease of installation versus long-term durability and watertight reliability in plumbing systems.

Leak Resistance and Durability Comparison

Slip-joint drains provide moderate leak resistance due to their adjustable compression fittings, allowing easy disassembly but potentially loosening over time. Solvent-weld drains form a permanent, chemical bond between pipes, ensuring superior leak resistance and enhanced durability under pressure and temperature variations. For long-term plumbing installations requiring minimal maintenance, solvent-weld drains are typically more reliable and resistant to leaks compared to slip-joint drains.

Maintenance and Repair: Which is Easier?

Slip-joint drains offer easier maintenance and repair due to their tool-free assembly, allowing quick disconnection for cleaning or replacement without special adhesives. Solvent-weld drains require chemical adhesives to join pipes permanently, making repairs more time-consuming and demanding solvent welding skills. For long-term ease, slip-joint drains reduce service costs and downtime by enabling straightforward disassembly and reuse.

Cost Analysis: Slip-Joint vs Solvent-Weld Drain Systems

Slip-joint drain systems generally have a higher initial cost due to more expensive fittings and easier installation processes, reducing labor expenses. Solvent-weld drain systems use cheaper PVC pipes and fittings but require professional skills for solvent welding, increasing installation time and potential maintenance costs. Over the long term, slip-joint drains offer greater flexibility and reusability, which can lead to cost savings in repairs compared to the permanent, less adaptable solvent-weld drains.

Typical Applications and Best Use Cases

Slip-joint drains are typically used in bathroom sinks and lavatories where easy disassembly for cleaning or repair is required, making them ideal for residential and light commercial applications. Solvent-weld drains, commonly employed in permanent plumbing installations like kitchen sinks and floor drains, offer superior leak resistance and durability by creating a strong, chemical-bonded joint. Best use cases for slip-joint drains involve environments needing frequent maintenance access, while solvent-weld drains excel in long-term, high-pressure drainage systems.

Building Codes and Compliance Considerations

Slip-joint drains offer easy disassembly for maintenance but may not meet all local building codes requiring permanent, leak-proof connections, making them less compliant in certain jurisdictions. Solvent-weld drains create a strong, sealed bond by chemically fusing PVC pipes, typically satisfying stringent code requirements for durability and watertight integrity. Compliance with plumbing codes often mandates solvent-weld drains in residential or commercial installations to prevent leaks and ensure long-term reliability.

Choosing the Right Drain for Your Plumbing Project

Slip-joint drains offer easy installation and maintenance with their adjustable fittings, making them ideal for temporary or DIY plumbing projects. Solvent-weld drains provide a stronger, permanent seal through chemical bonding, ensuring long-term leak resistance and durability in more demanding plumbing systems. Selecting the right drain depends on project requirements, with slip-joint best for flexibility and solvent-weld optimal for a secure, lasting connection.

Slip-joint drain vs Solvent-weld drain Infographic

productdif.com

productdif.com