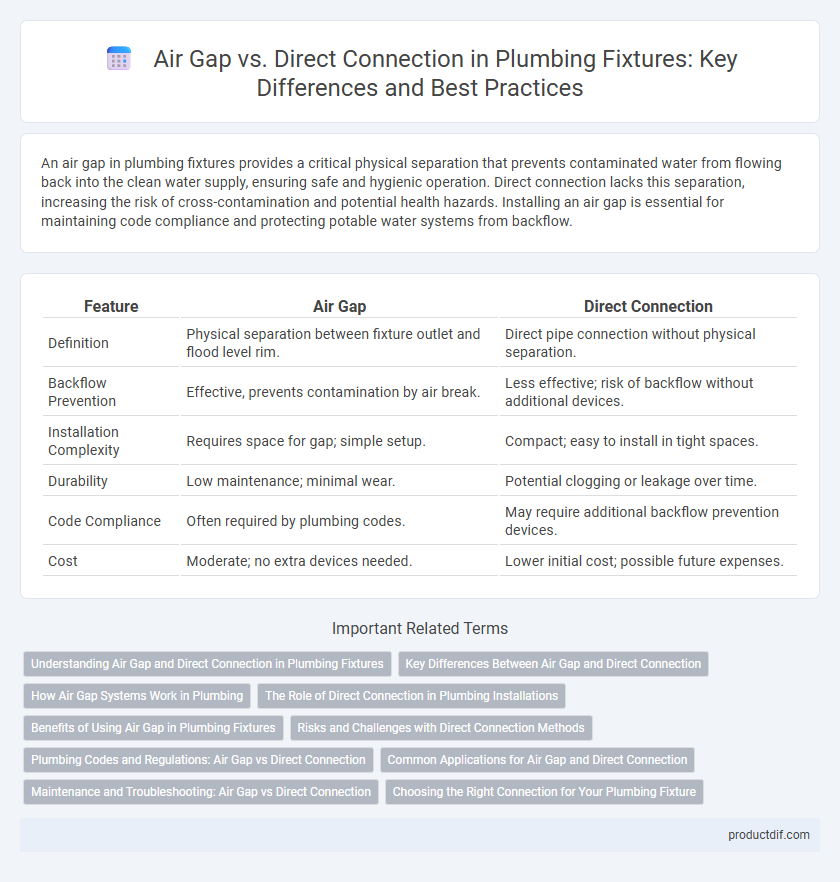

An air gap in plumbing fixtures provides a critical physical separation that prevents contaminated water from flowing back into the clean water supply, ensuring safe and hygienic operation. Direct connection lacks this separation, increasing the risk of cross-contamination and potential health hazards. Installing an air gap is essential for maintaining code compliance and protecting potable water systems from backflow.

Table of Comparison

| Feature | Air Gap | Direct Connection |

|---|---|---|

| Definition | Physical separation between fixture outlet and flood level rim. | Direct pipe connection without physical separation. |

| Backflow Prevention | Effective, prevents contamination by air break. | Less effective; risk of backflow without additional devices. |

| Installation Complexity | Requires space for gap; simple setup. | Compact; easy to install in tight spaces. |

| Durability | Low maintenance; minimal wear. | Potential clogging or leakage over time. |

| Code Compliance | Often required by plumbing codes. | May require additional backflow prevention devices. |

| Cost | Moderate; no extra devices needed. | Lower initial cost; possible future expenses. |

Understanding Air Gap and Direct Connection in Plumbing Fixtures

An air gap in plumbing fixtures prevents backflow by creating a physical separation between the water outlet and the flood level of a fixture, ensuring water cannot siphon back into the supply line. Direct connections link plumbing fixtures directly to the water supply without this separation, increasing the risk of contamination if backflow occurs. Building codes and health regulations typically require air gaps in critical applications, especially in potable water systems, to maintain sanitary conditions.

Key Differences Between Air Gap and Direct Connection

Air gaps prevent backflow contamination by providing a physical separation between the water outlet and the flood level of the fixture, ensuring safe potable water. Direct connections create a continuous path between the potable water supply and the fixture, increasing the risk of contamination if backflow occurs. Plumbing codes often mandate air gaps in critical applications to comply with health and safety standards.

How Air Gap Systems Work in Plumbing

Air gap systems in plumbing create a physical separation between the water outlet and the flood level of a fixture, preventing backflow contamination. This gap allows contaminated water to flow away instead of siphoning back into the potable water supply, ensuring safe and clean drinking water. Unlike direct connections, air gaps rely on a vertical space that complies with plumbing codes to maintain water system integrity and hygiene.

The Role of Direct Connection in Plumbing Installations

Direct connection in plumbing installations establishes a secure link between fixtures and water supply lines, ensuring efficient water flow without backflow risks. While lacking the protective barrier of an air gap, properly installed direct connections rely on backflow preventers to maintain water system integrity. This method is essential in applications where space constraints or design requirements make air gaps impractical.

Benefits of Using Air Gap in Plumbing Fixtures

An air gap in plumbing fixtures prevents backflow contamination by creating a physical separation between the water outlet and the flood level of the fixture, ensuring clean water supply and compliance with health codes. This design reduces the risk of cross-connections and protects potable water from pollutants or wastewater intrusion. Using an air gap enhances system safety, maintains water quality, and supports regulatory standards in residential and commercial plumbing installations.

Risks and Challenges with Direct Connection Methods

Direct connection methods in plumbing fixtures pose significant risks including cross-contamination and backflow, which can compromise potable water safety. Lack of an air gap eliminates a physical barrier, increasing the chance of wastewater siphoning back into the clean water supply. Ensuring compliance with plumbing codes and installing backflow prevention devices are critical to mitigating these challenges.

Plumbing Codes and Regulations: Air Gap vs Direct Connection

Plumbing codes strictly require an air gap between potable water supplies and potential contaminants to prevent backflow and ensure safe drinking water. Direct connections without proper backflow prevention devices are prohibited by most municipal plumbing regulations due to the increased risk of contamination. Compliance with standards like the Uniform Plumbing Code (UPC) and International Plumbing Code (IPC) mandates using air gaps or approved backflow preventers to maintain hygienic and code-compliant plumbing systems.

Common Applications for Air Gap and Direct Connection

Air gaps are commonly used in dishwasher and sink drain installations to prevent backflow and contamination by providing a physical separation between the fixture and the waste system. Direct connections are typically found in washing machine drains and water heaters where a sealed, uninterrupted flow is necessary for efficient operation. Choosing the appropriate method depends on local plumbing codes and the fixture's specific drainage requirements.

Maintenance and Troubleshooting: Air Gap vs Direct Connection

Air gaps require less frequent maintenance by preventing backflow contamination, reducing the risk of clogs and system failures. Direct connections often need regular inspection and cleaning to avoid siphoning and cross-contamination issues. Troubleshooting air gap systems typically involves checking for proper clearance and water flow, while direct connections demand vigilant monitoring for leaks and pressure imbalances.

Choosing the Right Connection for Your Plumbing Fixture

Selecting the appropriate connection for your plumbing fixture significantly impacts water safety and system efficiency; an air gap connection prevents backflow contamination by maintaining a physical separation between the water supply and fixture, meeting strict building codes. Direct connections offer a compact and cost-effective solution but require backflow prevention devices to ensure potable water protection. Prioritize compliance with local plumbing regulations and fixture requirements to choose between air gap and direct connection methods for optimal performance and health safety.

air gap vs direct connection Infographic

productdif.com

productdif.com