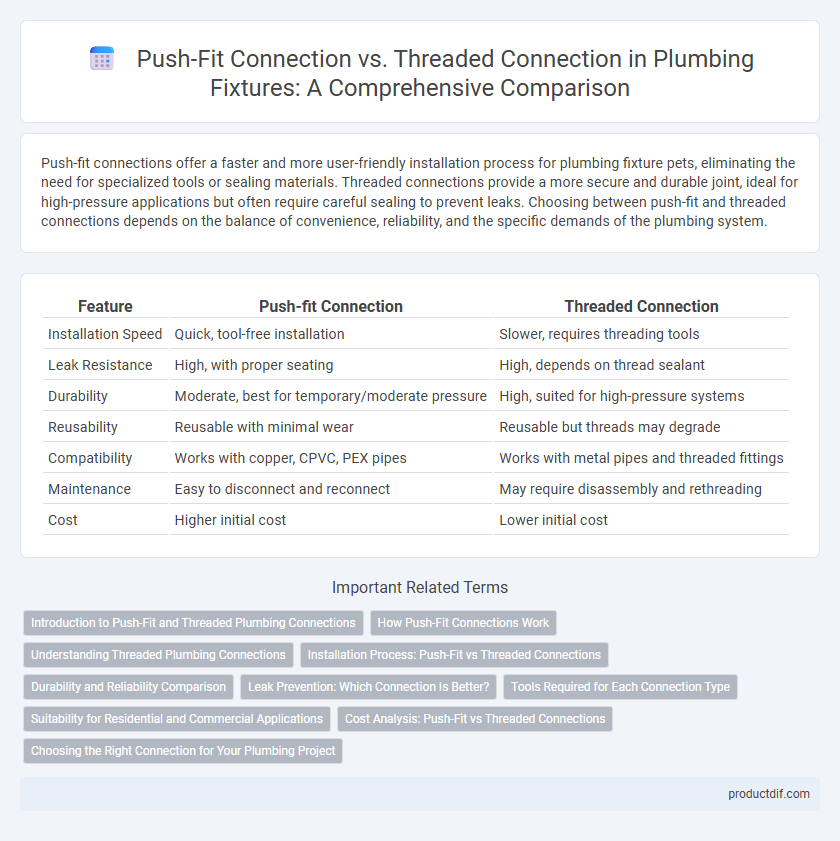

Push-fit connections offer a faster and more user-friendly installation process for plumbing fixture pets, eliminating the need for specialized tools or sealing materials. Threaded connections provide a more secure and durable joint, ideal for high-pressure applications but often require careful sealing to prevent leaks. Choosing between push-fit and threaded connections depends on the balance of convenience, reliability, and the specific demands of the plumbing system.

Table of Comparison

| Feature | Push-fit Connection | Threaded Connection |

|---|---|---|

| Installation Speed | Quick, tool-free installation | Slower, requires threading tools |

| Leak Resistance | High, with proper seating | High, depends on thread sealant |

| Durability | Moderate, best for temporary/moderate pressure | High, suited for high-pressure systems |

| Reusability | Reusable with minimal wear | Reusable but threads may degrade |

| Compatibility | Works with copper, CPVC, PEX pipes | Works with metal pipes and threaded fittings |

| Maintenance | Easy to disconnect and reconnect | May require disassembly and rethreading |

| Cost | Higher initial cost | Lower initial cost |

Introduction to Push-Fit and Threaded Plumbing Connections

Push-fit plumbing connections offer a tool-free, quick, and reliable method to join pipes, using a simple push mechanism that seals with internal O-rings for leak-proof performance. Threaded connections employ screw threads cut onto pipe ends or fittings, requiring sealing tape or compound to prevent leaks and typically demand more time and skill to assemble securely. Both methods serve essential roles in plumbing, with push-fit connections favored for ease and speed, while threaded connections provide strong, durable joints ideal for high-pressure systems.

How Push-Fit Connections Work

Push-fit connections create a secure seal by using an internal O-ring and stainless steel teeth to grip the pipe when inserted, eliminating the need for soldering or adhesives. The pipe is simply pushed into the fitting, where the O-ring compresses for watertight sealing and the teeth hold the pipe firmly in place. This method accelerates installation and reduces the risk of leaks compared to traditional threaded connections.

Understanding Threaded Plumbing Connections

Threaded plumbing connections use male and female threads to create a secure, leak-resistant seal, commonly found in metal pipes like brass, copper, and galvanized steel. Properly cutting, cleaning, and lubricating threads ensures tight assembly, while joint compounds or Teflon tape enhance sealing capabilities and prevent corrosion. Threaded connections offer durability and ease of disassembly, making them ideal for fixtures requiring frequent maintenance or replacement.

Installation Process: Push-Fit vs Threaded Connections

Push-fit connections offer a quicker installation process by enabling pipes to be joined without the need for soldering or specialized tools, reducing labor time and complexity. Threaded connections require precise alignment and sealing with tape or compound to prevent leaks, often involving longer preparation and assembly times. The push-fit method is especially advantageous in tight spaces or for retrofit projects, while threaded connections provide strong mechanical bonds suited for high-pressure applications.

Durability and Reliability Comparison

Push-fit connections offer strong resistance to leaks and withstand movement or vibration better due to their flexible sealing rings, making them highly durable for various plumbing applications. Threaded connections provide reliable mechanical strength through tightly interlocking threads, which can endure high pressure and temperature but may loosen over time without proper sealing compounds. Overall, push-fit fittings excel in ease of installation and consistent sealing, while threaded fittings are favored for long-term robustness in heavy-duty plumbing systems.

Leak Prevention: Which Connection Is Better?

Push-fit connections offer superior leak prevention due to their secure, watertight seals formed by internal O-rings and compression mechanisms, minimizing the risk of gaps and loosening over time. Threaded connections depend heavily on precise tightening and thread sealants like PTFE tape, which can degrade or be improperly applied, increasing the potential for leaks. For plumbing fixtures requiring reliable leak resistance and ease of installation, push-fit connections are generally the better choice.

Tools Required for Each Connection Type

Push-fit connections require minimal tools, often just a pipe cutter and a deburring tool, making installation quick and accessible for DIY enthusiasts and professionals. Threaded connections demand more specialized tools such as pipe wrenches, thread seal tape, and pipe threading machines to ensure secure and leak-free joints. The simplicity of push-fit tools contrasts sharply with the precision and effort needed for threading equipment in plumbing fixture assembly.

Suitability for Residential and Commercial Applications

Push-fit connections offer quick installation and flexibility, making them ideal for residential plumbing where ease of use and time-saving are priorities. Threaded connections provide a robust and leak-resistant seal, preferred in commercial applications requiring high durability and frequent maintenance. Both connection types serve distinct roles, with push-fit favored in domestic settings and threaded connections dominating industrial or large-scale plumbing projects.

Cost Analysis: Push-Fit vs Threaded Connections

Push-fit connections typically reduce labor costs by enabling faster installation and eliminating the need for specialized tools, making them more cost-effective for residential plumbing projects. Threaded connections, while generally cheaper per fitting, require more time and skill to install, increasing overall labor expenses in commercial or complex plumbing systems. Considering both material and labor costs, push-fit systems often provide greater value in projects prioritizing speed and ease of maintenance.

Choosing the Right Connection for Your Plumbing Project

Push-fit connections offer quick and tool-free installation, making them ideal for DIY projects and tight spaces, while threaded connections provide a more secure, leak-resistant seal suitable for high-pressure systems. Selecting the right connection depends on factors such as pipe material compatibility, project scale, and the need for future maintenance or adjustments. Evaluating these aspects helps ensure optimal durability and performance in residential or commercial plumbing applications.

Push-fit connection vs Threaded connection Infographic

productdif.com

productdif.com