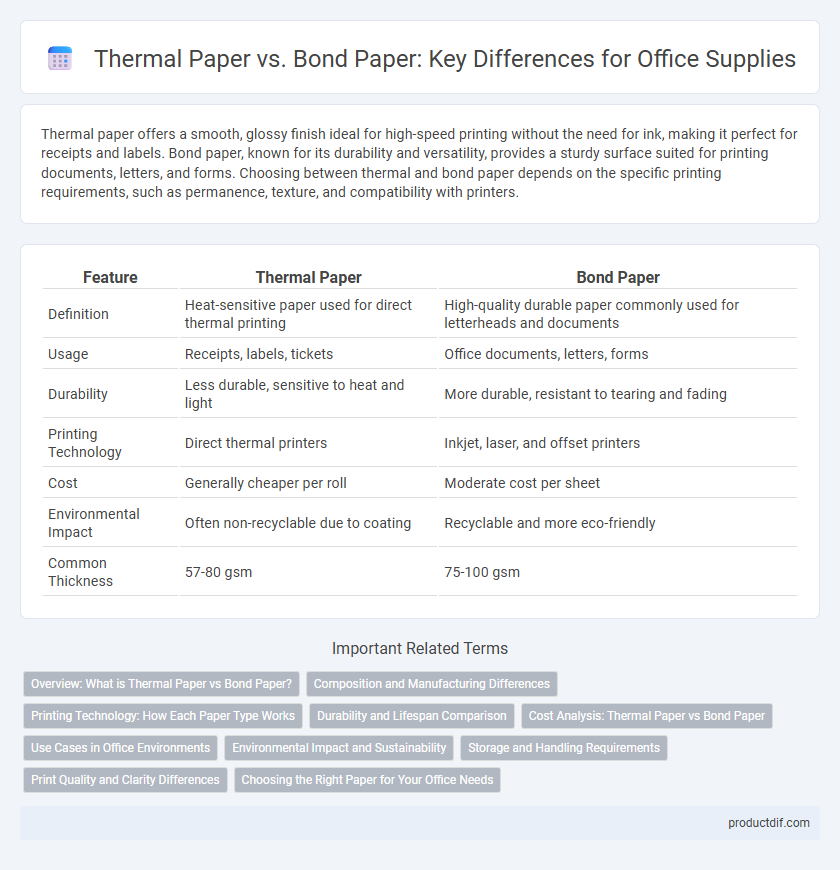

Thermal paper offers a smooth, glossy finish ideal for high-speed printing without the need for ink, making it perfect for receipts and labels. Bond paper, known for its durability and versatility, provides a sturdy surface suited for printing documents, letters, and forms. Choosing between thermal and bond paper depends on the specific printing requirements, such as permanence, texture, and compatibility with printers.

Table of Comparison

| Feature | Thermal Paper | Bond Paper |

|---|---|---|

| Definition | Heat-sensitive paper used for direct thermal printing | High-quality durable paper commonly used for letterheads and documents |

| Usage | Receipts, labels, tickets | Office documents, letters, forms |

| Durability | Less durable, sensitive to heat and light | More durable, resistant to tearing and fading |

| Printing Technology | Direct thermal printers | Inkjet, laser, and offset printers |

| Cost | Generally cheaper per roll | Moderate cost per sheet |

| Environmental Impact | Often non-recyclable due to coating | Recyclable and more eco-friendly |

| Common Thickness | 57-80 gsm | 75-100 gsm |

Overview: What is Thermal Paper vs Bond Paper?

Thermal paper is a special fine paper coated with a chemical that changes color when exposed to heat, commonly used in receipts and shipping labels for its fast, inkless printing. Bond paper is a high-quality, durable writing paper made from cotton or wood pulp, favored in offices for letterheads, official documents, and printing due to its strength and smooth surface. Understanding their differences helps businesses choose the right paper type for specific printing needs, balancing cost, appearance, and functionality.

Composition and Manufacturing Differences

Thermal paper is coated with a heat-sensitive layer composed primarily of dye and developer chemicals that react when exposed to thermal print heads, eliminating the need for ink. Bond paper, commonly made from wood pulp or cotton fibers, undergoes a traditional pulping and pressing process resulting in a strong, durable surface suitable for ink-based printing. The manufacturing of thermal paper involves precise chemical layering on a base substrate, while bond paper's production emphasizes fiber bonding and surface sizing for enhanced ink absorption and durability.

Printing Technology: How Each Paper Type Works

Thermal paper uses heat-sensitive coating that darkens when exposed to the thermal print head, making it ideal for direct thermal printers in receipts and labels without requiring ink or toner, which enhances speed and reduces maintenance. Bond paper relies on ink or toner applied by inkjet or laser printers, offering durability and versatility for documents, forms, and professional printing with sharp, long-lasting text and images. The choice between thermal and bond paper hinges on the specific printing technology and application requirements, influencing cost-efficiency and print quality.

Durability and Lifespan Comparison

Thermal paper offers a shorter lifespan, typically lasting between 5 to 7 years, due to its sensitivity to heat, light, and chemicals, which can cause fading and discoloration over time. In contrast, bond paper is known for its durability, often maintaining quality for several decades as it resists fading and physical wear better, making it ideal for archival documents and frequent handling. Choosing between thermal and bond paper depends heavily on the need for long-term preservation versus short-term, high-speed printing applications.

Cost Analysis: Thermal Paper vs Bond Paper

Thermal paper typically costs more upfront due to its specialized coating that enables heat-based printing, but it eliminates the need for ink or toner, reducing ongoing expenses. Bond paper is generally less expensive per sheet but requires additional costs for ink, toner, or ribbon, increasing operational expenditure over time. Analyzing total cost of ownership reveals thermal paper may be more cost-effective for high-volume printing environments, while bond paper suits lower-volume or multi-purpose uses.

Use Cases in Office Environments

Thermal paper is ideal for receipt printing, labels, and tickets due to its heat-sensitive coating that eliminates the need for ink, making it efficient for point-of-sale systems and quick documentation. Bond paper, known for its durability and smooth texture, is preferred for official documents, reports, and forms that require printing and photocopying in office environments. Choosing between thermal and bond paper depends on whether the application requires high-speed thermal printing or long-lasting, high-quality print output.

Environmental Impact and Sustainability

Thermal paper often contains chemical coatings such as BPA or BPS, which pose environmental hazards during disposal and limit recyclability compared to bond paper made from untreated wood pulp. Bond paper typically supports sustainable forestry practices and is easier to recycle, reducing landfill accumulation and promoting a circular economy. Choosing bond paper over thermal paper contributes to lower ecological footprints and better compliance with environmental regulations.

Storage and Handling Requirements

Thermal paper requires storage in a cool, dry environment away from direct sunlight and heat sources to prevent premature darkening and loss of image quality. Bond paper, being more stable, tolerates a wider range of storage conditions but should still be kept in a moisture-controlled environment to prevent warping or curling. Proper handling of thermal paper includes avoiding prolonged exposure to oils and fingerprints, whereas bond paper is less sensitive and easier to handle without special precautions.

Print Quality and Clarity Differences

Thermal paper offers sharp, high-contrast print quality ideal for receipts and labels but may fade over time due to heat sensitivity. Bond paper delivers consistent print clarity with excellent durability, making it suitable for official documents and long-term storage. The choice between thermal and bond paper depends on the need for immediate print quality versus archival longevity in office environments.

Choosing the Right Paper for Your Office Needs

Thermal paper offers fast, high-quality prints ideal for receipts and labels, utilizing heat-sensitive technology without ink, making it cost-effective for point-of-sale systems. Bond paper, known for its durability and smooth texture, suits letterheads, reports, and official documents requiring ink printing, ensuring longevity and professional appearance. Selecting the right paper depends on your office's primary printing needs, balancing cost-efficiency with print quality and document type.

Thermal Paper vs Bond Paper Infographic

productdif.com

productdif.com