Label makers offer portable, all-in-one solutions ideal for quick, everyday labeling tasks in office supply pet environments, featuring built-in keyboards and displays for easy use. Label printers require connection to computers and provide higher resolution and customizable label options, making them suitable for bulk printing and professional-quality labels. Choosing between a label maker and a label printer depends on the balance between convenience, speed, and the complexity of labeling needs.

Table of Comparison

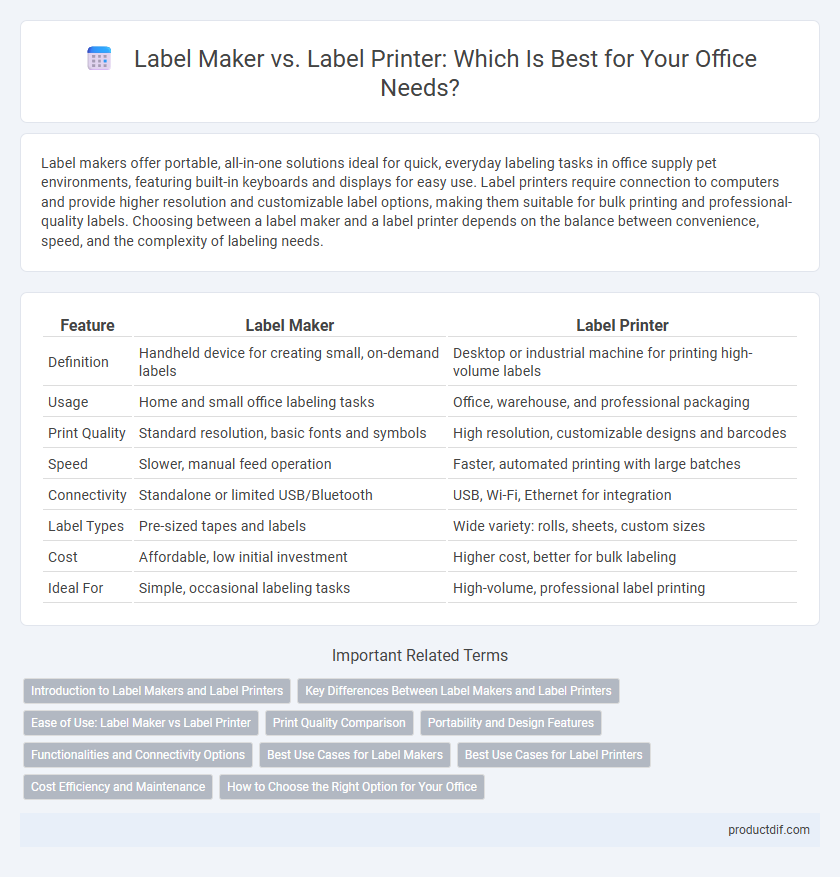

| Feature | Label Maker | Label Printer |

|---|---|---|

| Definition | Handheld device for creating small, on-demand labels | Desktop or industrial machine for printing high-volume labels |

| Usage | Home and small office labeling tasks | Office, warehouse, and professional packaging |

| Print Quality | Standard resolution, basic fonts and symbols | High resolution, customizable designs and barcodes |

| Speed | Slower, manual feed operation | Faster, automated printing with large batches |

| Connectivity | Standalone or limited USB/Bluetooth | USB, Wi-Fi, Ethernet for integration |

| Label Types | Pre-sized tapes and labels | Wide variety: rolls, sheets, custom sizes |

| Cost | Affordable, low initial investment | Higher cost, better for bulk labeling |

| Ideal For | Simple, occasional labeling tasks | High-volume, professional label printing |

Introduction to Label Makers and Label Printers

Label makers are compact devices designed for creating adhesive labels quickly and efficiently, typically used for small-scale office organization and identification tasks. Label printers cater to more extensive labeling needs, offering higher resolution and the ability to print on various materials, ideal for professional environments requiring durable and customizable labels. Both tools enhance office productivity by providing clear, precise labeling solutions for files, equipment, and storage.

Key Differences Between Label Makers and Label Printers

Label makers are compact, portable devices designed for quick, on-the-spot labeling with built-in keyboards and small displays, ideal for simple tasks like file folders and name tags. Label printers connect to computers or mobile devices, offering higher resolution, greater customization, and faster printing speeds suitable for large-scale or detailed labeling projects. Key differences include portability, print quality, connectivity options, and intended usage scenarios in office environments.

Ease of Use: Label Maker vs Label Printer

Label makers typically feature integrated keyboards and small screens, making them easy to operate for quick, on-the-spot labeling without needing additional devices. Label printers often require connection to a computer or smartphone app, which can add complexity but allows for more advanced design options. For simple, straightforward labeling tasks, label makers offer superior ease of use compared to the more versatile but tech-dependent label printers.

Print Quality Comparison

Label printers typically offer higher print resolution than label makers, delivering sharper, more detailed text and graphics ideal for professional use. Most label printers utilize thermal transfer or direct thermal technology, producing durable, smudge-resistant labels with vibrant colors and fine lines. In comparison, label makers often use lower-resolution dye-based ink or embossing, resulting in less precise prints suitable for basic labeling needs.

Portability and Design Features

Label makers offer enhanced portability with compact, handheld designs ideal for on-the-go labeling, while label printers tend to be larger and designed for desktop use, providing higher printing speeds and versatile connectivity options. The ergonomic design of label makers emphasizes ease of use and battery-powered operation, contrasting with label printers' robust construction that supports continuous, high-volume output. Portability in label makers suits mobile professionals, whereas label printers are better suited for stationary office environments requiring diverse label formats.

Functionalities and Connectivity Options

Label makers offer integrated keyboards and small displays for creating labels directly on the device, making them ideal for quick, on-the-go labeling tasks, while label printers rely on external devices like computers or smartphones for design input, supporting more complex and customizable labels. Connectivity options for label makers typically include USB and Bluetooth, allowing portable use, whereas label printers provide a broader range of connectivity such as Wi-Fi, Ethernet, USB, and Bluetooth to support networked office environments and high-volume printing needs. Functionalities of label printers often include higher resolution printing, compatibility with various label materials and sizes, and advanced software for batch printing, contrasting with label makers' focus on simplicity and immediate labeling.

Best Use Cases for Label Makers

Label makers are best suited for quick, small-scale labeling tasks in office environments, such as organizing files, folders, and office supplies. They offer portability and ease of use, making them ideal for on-the-spot labeling needs and frequent updates to labels. Their compact design and affordability make them perfect for environments requiring fast, efficient labeling without the need for high-volume printing.

Best Use Cases for Label Printers

Label printers excel in high-volume printing environments such as warehouses, retail stores, and manufacturing facilities where durability and speed are essential. They produce professional-grade labels on various materials, making them ideal for barcode labeling, shipping tags, and asset tracking. Compared to label makers, label printers offer superior resolution and connectivity options, enhancing efficiency in large-scale labeling tasks.

Cost Efficiency and Maintenance

Label makers typically offer lower upfront costs and simpler maintenance, making them cost-efficient for small-scale or occasional labeling tasks. Label printers, while more expensive initially, provide higher volume output and durable labels, reducing long-term costs for businesses with frequent labeling needs. Maintenance for label printers often involves replacing print heads and specialized parts, whereas label makers usually require only occasional battery or tape replacement.

How to Choose the Right Option for Your Office

Choosing between a label maker and a label printer depends on your office's labeling needs, volume, and budget. Label makers offer portability and ease of use for small-scale or on-the-go labeling tasks, while label printers provide higher-quality, customizable labels suitable for bulk printing and professional settings. Evaluate factors like print speed, label material compatibility, connectivity options, and maintenance requirements to select the most efficient and cost-effective device for your office environment.

Label Maker vs Label Printer Infographic

productdif.com

productdif.com