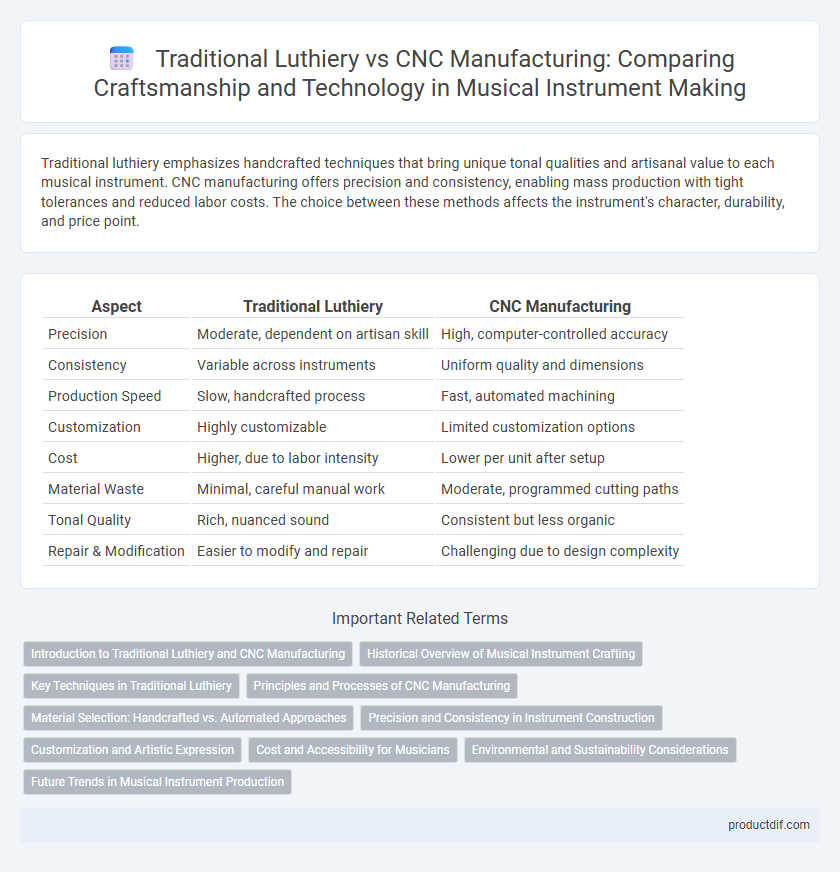

Traditional luthiery emphasizes handcrafted techniques that bring unique tonal qualities and artisanal value to each musical instrument. CNC manufacturing offers precision and consistency, enabling mass production with tight tolerances and reduced labor costs. The choice between these methods affects the instrument's character, durability, and price point.

Table of Comparison

| Aspect | Traditional Luthiery | CNC Manufacturing |

|---|---|---|

| Precision | Moderate, dependent on artisan skill | High, computer-controlled accuracy |

| Consistency | Variable across instruments | Uniform quality and dimensions |

| Production Speed | Slow, handcrafted process | Fast, automated machining |

| Customization | Highly customizable | Limited customization options |

| Cost | Higher, due to labor intensity | Lower per unit after setup |

| Material Waste | Minimal, careful manual work | Moderate, programmed cutting paths |

| Tonal Quality | Rich, nuanced sound | Consistent but less organic |

| Repair & Modification | Easier to modify and repair | Challenging due to design complexity |

Introduction to Traditional Luthiery and CNC Manufacturing

Traditional luthiery involves handcrafted techniques passed down through generations, emphasizing artisanal skill and the nuanced shaping of wood to create unique, high-quality musical instruments. CNC manufacturing utilizes computer-controlled machines to precisely cut and shape instrument components, enabling rapid production with consistent accuracy. The contrast between these methods highlights the blend of craftsmanship and technology in modern instrument making.

Historical Overview of Musical Instrument Crafting

Traditional luthiery dates back centuries, characterized by handcrafted wooden instruments shaped by skilled artisans using hand tools and time-honored techniques. CNC manufacturing emerged in the late 20th century, employing computer-controlled machines to produce precise, consistent components at a faster rate. This shift from manual craftsmanship to automated production represents a significant evolution in musical instrument crafting, blending historical artistry with modern technology.

Key Techniques in Traditional Luthiery

Traditional luthiery relies on hand tools such as chisels, planes, and scrapers to shape tonewoods, ensuring precise craftsmanship that vibrant sound qualities demand. Techniques like hand carving the soundboard and meticulously bending the sides preserve the instrument's acoustic integrity and unique tonal characteristics. Skilled luthiers also employ intricate joinery and hand-applied finishes that enhance resonance and durability, emphasizing artisanal quality over mass production.

Principles and Processes of CNC Manufacturing

CNC manufacturing in musical instrument production relies on computer-controlled precision cutting and carving, enabling high repeatability and intricate design details unattainable through traditional hand tools. The process starts with digital 3D modeling, which guides automated machinery to shape wood components with consistent accuracy and reduced material waste. This method accelerates production timelines and enhances uniformity, contrasting with the artisanal craftsmanship and variability inherent in traditional luthiery techniques.

Material Selection: Handcrafted vs. Automated Approaches

Traditional luthiery emphasizes the careful selection of tonewoods like spruce, maple, and rosewood based on grain pattern, density, and resonance, ensuring each instrument's unique acoustic character. CNC manufacturing relies on standardized, pre-tested materials optimized for consistency and repeatability, using computer-controlled precision to minimize defects and waste. Both approaches impact the final sound quality, with handcrafted methods favoring nuanced tonal variation and CNC processes enabling scalable production with uniform material properties.

Precision and Consistency in Instrument Construction

Traditional luthiery offers handcrafted precision where skilled artisans shape each instrument with meticulous attention to detail, resulting in unique tonal characteristics and subtle variations. CNC manufacturing ensures unparalleled consistency and accuracy by using computer-controlled machinery to replicate exact specifications for every instrument component. This method reduces human error and maintains high precision across large production runs, enabling uniform quality and reliable performance.

Customization and Artistic Expression

Traditional luthiery offers unparalleled customization and artistic expression through handcrafted detailing, allowing luthiers to tailor each instrument to the musician's unique preferences and tonal requirements. CNC manufacturing provides precise repeatability and consistency but often limits the nuanced craftsmanship and individualized character found in handmade instruments. The balance between traditional artistry and digital precision shapes the evolving landscape of musical instrument creation.

Cost and Accessibility for Musicians

Traditional luthiery involves handcrafted instruments that often carry higher costs due to labor-intensive techniques and premium materials, limiting accessibility for many musicians. CNC manufacturing reduces production expenses by utilizing automated processes, making quality instruments more affordable and widely available. The shift to CNC technology democratizes access to musical instruments but may sacrifice some artisanal uniqueness valued by professional players.

Environmental and Sustainability Considerations

Traditional luthiery relies on handcrafting techniques using sustainably sourced tonewoods, minimizing waste through precision and reuse of materials. CNC manufacturing offers higher efficiency and consistency but often depends on synthetic adhesives and finishes with environmental concerns and generates more industrial waste. Sustainable practices in both methods include sourcing certified woods, reducing chemical use, and promoting recycling to mitigate environmental impact.

Future Trends in Musical Instrument Production

Future trends in musical instrument production highlight a blend of traditional luthiery craftsmanship and CNC manufacturing technology, leveraging the precision of computer-controlled machinery while preserving artisanal quality. Innovations in CNC machining enable consistent, scalable production of complex components, reducing costs and enhancing customization capabilities for instruments such as guitars, violins, and pianos. The integration of digital design tools with traditional hand-finishing techniques is anticipated to drive a new era of hybrid manufacturing, optimizing both sound performance and aesthetic detail.

Traditional luthiery vs CNC manufacturing Infographic

productdif.com

productdif.com