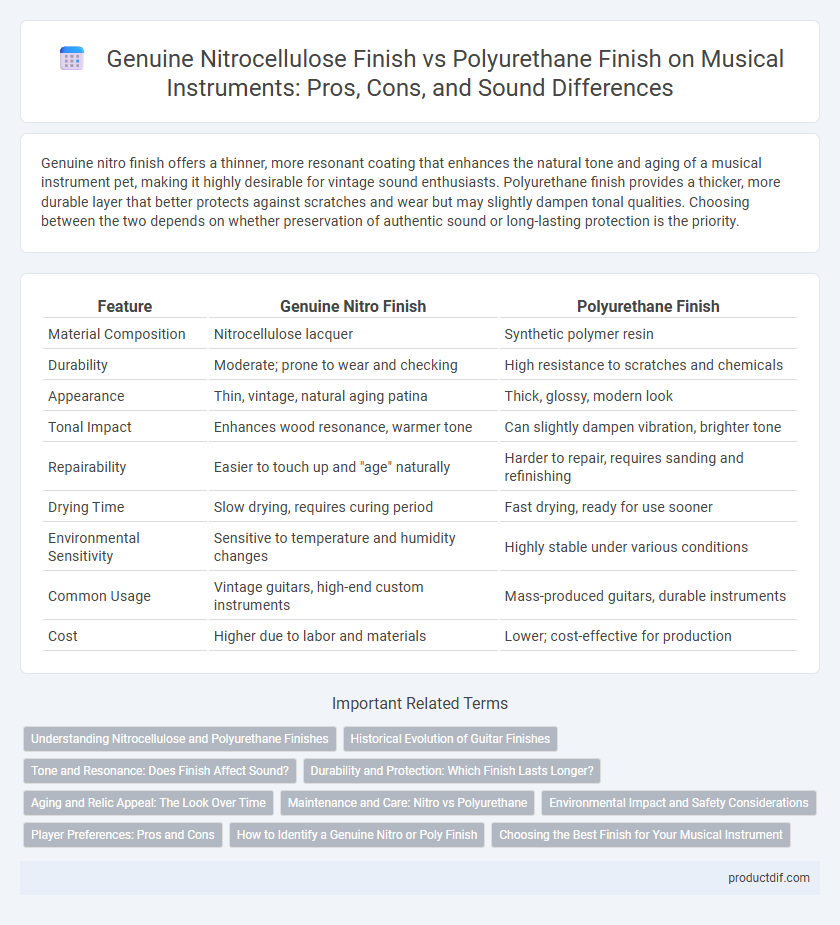

Genuine nitro finish offers a thinner, more resonant coating that enhances the natural tone and aging of a musical instrument pet, making it highly desirable for vintage sound enthusiasts. Polyurethane finish provides a thicker, more durable layer that better protects against scratches and wear but may slightly dampen tonal qualities. Choosing between the two depends on whether preservation of authentic sound or long-lasting protection is the priority.

Table of Comparison

| Feature | Genuine Nitro Finish | Polyurethane Finish |

|---|---|---|

| Material Composition | Nitrocellulose lacquer | Synthetic polymer resin |

| Durability | Moderate; prone to wear and checking | High resistance to scratches and chemicals |

| Appearance | Thin, vintage, natural aging patina | Thick, glossy, modern look |

| Tonal Impact | Enhances wood resonance, warmer tone | Can slightly dampen vibration, brighter tone |

| Repairability | Easier to touch up and "age" naturally | Harder to repair, requires sanding and refinishing |

| Drying Time | Slow drying, requires curing period | Fast drying, ready for use sooner |

| Environmental Sensitivity | Sensitive to temperature and humidity changes | Highly stable under various conditions |

| Common Usage | Vintage guitars, high-end custom instruments | Mass-produced guitars, durable instruments |

| Cost | Higher due to labor and materials | Lower; cost-effective for production |

Understanding Nitrocellulose and Polyurethane Finishes

Nitrocellulose finishes, derived from cellulose treated with nitric acid, offer a thin, breathable coating that enhances resonance and vintage aesthetics on musical instruments, commonly favored on high-end guitars. Polyurethane finishes, made from synthetic polymers, provide a thicker, more durable coating that resists scratches and wear, ideal for instruments requiring long-lasting protection with minimal maintenance. Understanding the chemical composition and application of nitrocellulose and polyurethane finishes helps musicians choose the optimal balance between tonal quality, appearance, and durability.

Historical Evolution of Guitar Finishes

Guitar finishes evolved from traditional nitrocellulose lacquer, developed in the 1920s for its thin, breathable qualities that enhance resonance, to polyurethane finishes introduced in the 1960s for superior durability and chemical resistance. Nitro finishes age naturally, creating a vintage appeal with gradual yellowing and checking, while polyurethane offers a thicker, glossy surface that resists wear but can stifle tonal nuances. This evolution reflects a trade-off between preserving classic tonal characteristics and meeting modern demands for finish longevity and maintenance ease.

Tone and Resonance: Does Finish Affect Sound?

Genuine nitrocellulose finish allows wood to breathe and age naturally, enhancing resonance and producing a warmer, more vibrant tone compared to polyurethane finishes. Polyurethane finish creates a thicker, more protective layer that can dampen vibrations, resulting in slightly muted sound characteristics. Many musicians prefer nitro finishes for their ability to contribute to tonal complexity and dynamic response over time.

Durability and Protection: Which Finish Lasts Longer?

Genuine nitro finish offers a thinner, more breathable protective layer that allows the wood to resonate naturally but is more prone to wear, chipping, and yellowing over time. Polyurethane finish provides a thicker, tougher coating that resists scratches, moisture, and UV damage, making it significantly more durable and longer-lasting. For musicians seeking maximum protection and longevity, polyurethane finish outperforms nitro finish in preserving the instrument's appearance and structural integrity.

Aging and Relic Appeal: The Look Over Time

Genuine nitro finish on musical instruments naturally ages with fine cracks and a warm amber tint, enhancing the vintage relic appeal. Polyurethane finishes resist wear, maintaining a glossy and uniform appearance but lacking the authentic aging character. Collectors and players seeking a time-worn look often prefer nitro for its evolving patina and organic texture changes.

Maintenance and Care: Nitro vs Polyurethane

Genuine nitro finish requires careful maintenance as it is more susceptible to scratches, dings, and discoloration from exposure to sunlight and humidity, necessitating gentle cleaning with a soft, dry cloth and avoidance of harsh chemicals. Polyurethane finishes offer superior durability and resistance to wear, making them easier to maintain with simple wipe-downs using mild soap and water, ideal for heavy-use instruments. Choosing between nitro and polyurethane finishes depends on the player's preference for vintage aesthetics with higher maintenance or modern resilience with low upkeep.

Environmental Impact and Safety Considerations

Genuine nitro finish, made from cellulose nitrate, is biodegradable but releases volatile organic compounds (VOCs) and toxic fumes during application and curing, posing health risks without proper ventilation. Polyurethane finishes are more chemically stable and emit fewer VOCs, making them safer for indoor use and less harmful to the environment over the long term. Disposal of polyurethane finishes requires careful handling due to their synthetic chemical content, while nitro finishes break down more naturally but demand stringent safety precautions during use.

Player Preferences: Pros and Cons

Genuine nitro finish offers superior resonance and vintage tonal qualities preferred by seasoned guitarists seeking authentic sound and feel, but it requires careful maintenance due to its susceptibility to wear and cracking. Polyurethane finish provides robust durability and resistance to scratches and moisture, making it ideal for players needing low-maintenance instruments without compromising playability. Players favor nitro for expressive tonal dynamics while choosing polyurethane for reliability during extensive touring and heavy usage.

How to Identify a Genuine Nitro or Poly Finish

Identifying a genuine nitro finish involves examining the surface for slight imperfections, a thinner coating, and a characteristic amber hue that ages naturally over time. Polyurethane finishes appear thicker, glossier, and more durable, often lacking the subtle texture and warmth found in nitro finishes. Testing by gently warming the surface or checking for a harder, chemical-like odor can also indicate a polyurethane finish compared to the more delicate, organic scent of nitrocellulose lacquer.

Choosing the Best Finish for Your Musical Instrument

Genuine nitro finish offers a thin, breathable coating that enhances the resonance and vintage tone of musical instruments, allowing the wood to age naturally over time. Polyurethane finish provides a durable, glossy protective layer resistant to scratches and moisture, ideal for heavy use and maintaining long-term cosmetic appeal. Selecting the best finish depends on balancing tonal preference, maintenance needs, and the instrument's intended environment.

Genuine Nitro Finish vs Polyurethane Finish Infographic

productdif.com

productdif.com