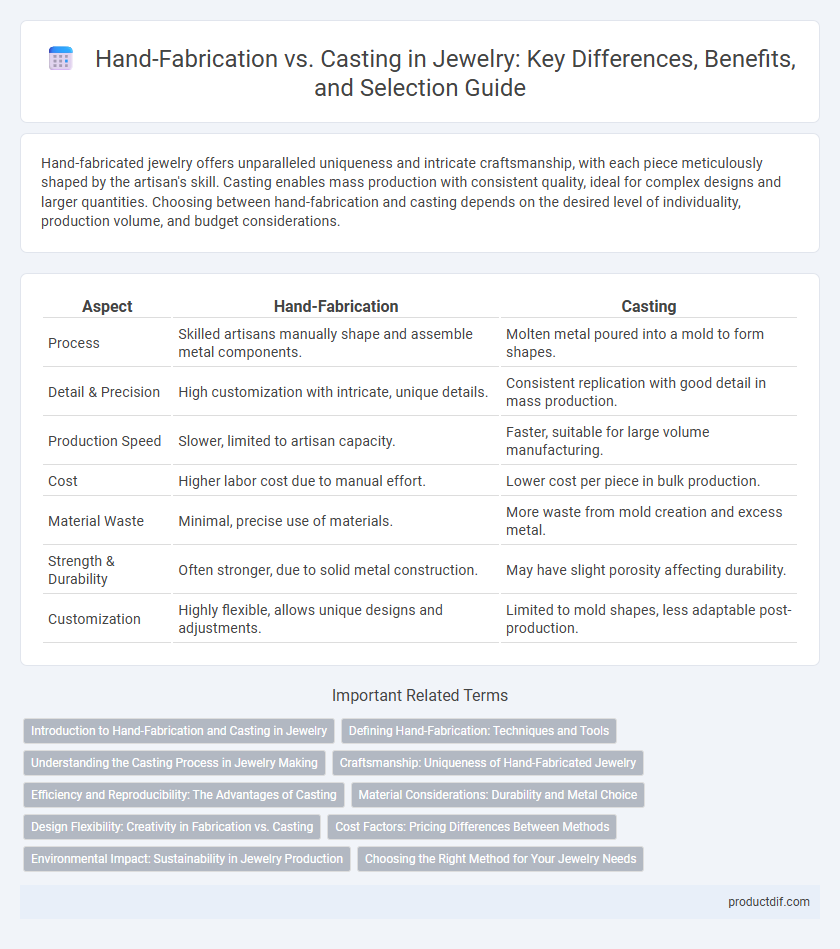

Hand-fabricated jewelry offers unparalleled uniqueness and intricate craftsmanship, with each piece meticulously shaped by the artisan's skill. Casting enables mass production with consistent quality, ideal for complex designs and larger quantities. Choosing between hand-fabrication and casting depends on the desired level of individuality, production volume, and budget considerations.

Table of Comparison

| Aspect | Hand-Fabrication | Casting |

|---|---|---|

| Process | Skilled artisans manually shape and assemble metal components. | Molten metal poured into a mold to form shapes. |

| Detail & Precision | High customization with intricate, unique details. | Consistent replication with good detail in mass production. |

| Production Speed | Slower, limited to artisan capacity. | Faster, suitable for large volume manufacturing. |

| Cost | Higher labor cost due to manual effort. | Lower cost per piece in bulk production. |

| Material Waste | Minimal, precise use of materials. | More waste from mold creation and excess metal. |

| Strength & Durability | Often stronger, due to solid metal construction. | May have slight porosity affecting durability. |

| Customization | Highly flexible, allows unique designs and adjustments. | Limited to mold shapes, less adaptable post-production. |

Introduction to Hand-Fabrication and Casting in Jewelry

Hand-fabrication in jewelry involves shaping and assembling metal components using tools like saws, files, and soldering equipment to create unique, custom pieces. Casting uses molten metal poured into molds to replicate intricate designs efficiently, often employed for mass production of jewelry. Each technique offers distinct advantages, with hand-fabrication emphasizing craftsmanship and detail, while casting provides speed and consistency.

Defining Hand-Fabrication: Techniques and Tools

Hand-fabrication in jewelry involves the meticulous process of crafting pieces manually using essential tools such as saws, files, hammers, and soldering equipment. Techniques like sawing, bending, forming, and soldering enable jewelers to create unique, customized designs with intricate details and superior structural integrity. This artisanal method demands high skill and precision, distinguishing handcrafted jewelry from mass-produced cast items.

Understanding the Casting Process in Jewelry Making

The casting process in jewelry making involves creating a detailed wax model that is encased in a heat-resistant mold, which is then heated to melt away the wax, leaving a cavity for molten metal to be poured in. This technique allows for the production of intricate and consistent designs that would be challenging to achieve through hand-fabrication alone. Casting offers efficiency and precision in producing complex jewelry pieces, making it essential for replicating detailed elements with high accuracy.

Craftsmanship: Uniqueness of Hand-Fabricated Jewelry

Hand-fabricated jewelry showcases unparalleled craftsmanship through meticulous techniques that allow artisans to create unique, one-of-a-kind pieces with intricate details impossible to replicate by casting. This method emphasizes precision and personal touch, resulting in jewelry that reflects the artist's skill and creativity in every curve and texture. Unlike casting, hand fabrication produces bespoke designs with subtle variations, enhancing the exclusivity and artistic value of each item.

Efficiency and Reproducibility: The Advantages of Casting

Casting in jewelry production significantly enhances efficiency by enabling rapid creation of multiple identical pieces from a single mold, reducing time and labor compared to hand-fabrication. This method ensures high reproducibility with consistent quality and intricate detail that can be challenging to achieve manually. Jewelry casting supports large-scale production, meeting demand while maintaining precision and minimizing material waste.

Material Considerations: Durability and Metal Choice

Hand-fabrication in jewelry allows for the use of diverse metals, including precious gold, platinum, and alternative metals, offering enhanced durability through solid construction. Casting techniques often involve molten metal poured into molds, which can introduce microscopic porosity affecting the metal's strength, especially in metals like silver and bronze. Selecting the right metal depends on desired durability; platinum's high density makes it ideal for casting, while hand-fabrication suits malleable metals like gold for intricate, long-lasting designs.

Design Flexibility: Creativity in Fabrication vs. Casting

Hand-fabrication offers unparalleled design flexibility by allowing jewelers to manipulate metals and gemstones directly, creating intricate, one-of-a-kind pieces tailored to specific artistic visions. Casting is efficient for producing multiple identical items but limits customization due to its reliance on molds, making complex adjustments challenging. Designers seeking unique, customizable jewelry often prefer hand-fabrication for its ability to accommodate complex shapes and personalized details.

Cost Factors: Pricing Differences Between Methods

Hand-fabrication jewelry typically incurs higher labor costs due to the extensive time and skill required, making it more expensive than casting. Casting benefits from economies of scale, allowing multiple pieces to be produced quickly and at a lower cost per unit. Material waste and tooling expenses also influence pricing, with hand-fabricated pieces often generating less waste but demanding specialized tools.

Environmental Impact: Sustainability in Jewelry Production

Hand-fabrication in jewelry production significantly reduces environmental impact by minimizing waste and energy consumption compared to casting methods. Casting often involves melting metals, which requires higher energy usage and can release harmful emissions, whereas hand-fabrication uses precise techniques that generate less waste and promote sustainability. Choosing hand-fabricated jewelry aligns with eco-friendly practices by supporting responsible material use and reducing the carbon footprint associated with metal casting processes.

Choosing the Right Method for Your Jewelry Needs

Hand-fabrication offers unparalleled precision and customization, making it ideal for unique, one-of-a-kind jewelry pieces that demand detailed craftsmanship. Casting provides a cost-effective solution for producing multiple copies of intricate designs with consistent quality, suitable for larger production runs. Selecting the right method depends on factors such as budget, design complexity, and production scale, ensuring that your jewelry meets both aesthetic and functional requirements.

Hand-fabrication vs casting Infographic

productdif.com

productdif.com