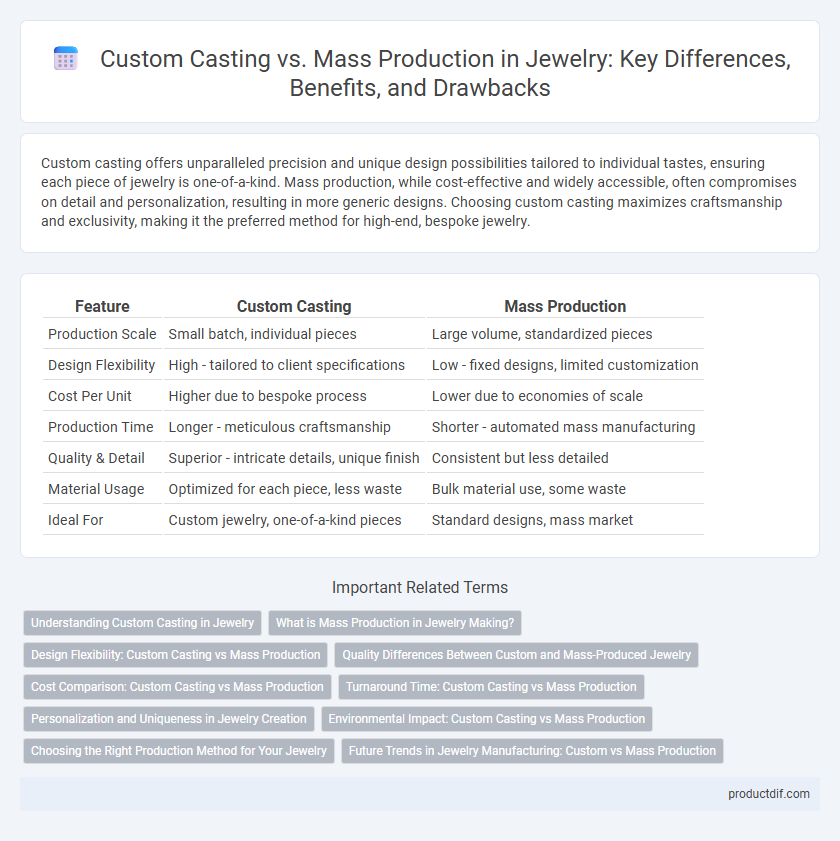

Custom casting offers unparalleled precision and unique design possibilities tailored to individual tastes, ensuring each piece of jewelry is one-of-a-kind. Mass production, while cost-effective and widely accessible, often compromises on detail and personalization, resulting in more generic designs. Choosing custom casting maximizes craftsmanship and exclusivity, making it the preferred method for high-end, bespoke jewelry.

Table of Comparison

| Feature | Custom Casting | Mass Production |

|---|---|---|

| Production Scale | Small batch, individual pieces | Large volume, standardized pieces |

| Design Flexibility | High - tailored to client specifications | Low - fixed designs, limited customization |

| Cost Per Unit | Higher due to bespoke process | Lower due to economies of scale |

| Production Time | Longer - meticulous craftsmanship | Shorter - automated mass manufacturing |

| Quality & Detail | Superior - intricate details, unique finish | Consistent but less detailed |

| Material Usage | Optimized for each piece, less waste | Bulk material use, some waste |

| Ideal For | Custom jewelry, one-of-a-kind pieces | Standard designs, mass market |

Understanding Custom Casting in Jewelry

Custom casting in jewelry involves creating unique pieces using a mold crafted specifically for an individual design, allowing for intricate detailing and personalization not achievable through mass production. This process enables artisans to work with precious metals like gold, silver, and platinum, ensuring high-quality finishes and precise replication of custom designs. Understanding the benefits of custom casting includes recognizing its role in producing one-of-a-kind jewelry that reflects personal style and craftsmanship excellence.

What is Mass Production in Jewelry Making?

Mass production in jewelry making involves creating large quantities of identical pieces using standardized molds and automated processes to ensure consistency and efficiency. This method significantly lowers manufacturing costs and shortens production time compared to handcrafted techniques. It is ideal for producing popular designs at scale, meeting high consumer demand with uniform quality.

Design Flexibility: Custom Casting vs Mass Production

Custom casting offers unparalleled design flexibility, allowing intricate and unique jewelry designs tailored to individual preferences and complex shapes. Mass production relies on standardized molds that limit customization, resulting in repetitive patterns and less intricate detailing. This distinction significantly impacts the ability to achieve personalized aesthetics and elaborate craftsmanship in jewelry pieces.

Quality Differences Between Custom and Mass-Produced Jewelry

Custom casting delivers superior quality jewelry by allowing precise control over design details and material selection, resulting in unique, durable pieces with excellent craftsmanship. Mass production often sacrifices detail and durability for speed and cost-efficiency, leading to uniform but less refined jewelry. The difference in quality between custom and mass-produced jewelry is evident in the finishing, weight distribution, and resilience of the final product.

Cost Comparison: Custom Casting vs Mass Production

Custom casting often incurs higher initial costs due to mold creation and intricate craftsmanship, but it allows for unique, detailed designs tailored to individual preferences. Mass production reduces unit costs significantly by leveraging standardized processes and bulk material procurement, making it more economical for large quantities. Businesses must weigh the premium price of custom casting against the scalability and affordability of mass production based on their target market and production volume.

Turnaround Time: Custom Casting vs Mass Production

Custom casting typically requires a longer turnaround time due to the detailed design process and precise mold creation, often taking several weeks to complete a single piece. Mass production leverages standardized molds and automated processes, drastically reducing the turnaround time to days or even hours for large quantities. Efficient scheduling and advanced machinery in mass production ensure rapid delivery, while custom casting prioritizes craftsmanship and unique detailing despite extended timelines.

Personalization and Uniqueness in Jewelry Creation

Custom casting in jewelry creation allows for unparalleled personalization, enabling artisans to craft unique pieces tailored precisely to individual preferences and measurements. Mass production, while efficient and cost-effective, often results in limited design variations and lacks the distinctiveness found in bespoke jewelry. Choosing custom casting ensures a one-of-a-kind accessory that reflects personal style and sentimental value, setting it apart from the uniformity of mass-produced items.

Environmental Impact: Custom Casting vs Mass Production

Custom casting significantly reduces environmental impact by minimizing material waste and energy consumption compared to mass production in jewelry manufacturing. Mass production often relies on large-scale processes that generate excess metal scraps and emissions, contributing to ecological degradation. Prioritizing custom casting supports sustainable practices by optimizing resource use and reducing carbon footprint in the jewelry industry.

Choosing the Right Production Method for Your Jewelry

Custom casting offers unparalleled precision and unique designs tailored to individual preferences, making it ideal for bespoke jewelry pieces. Mass production provides cost-efficiency and consistent quality across large quantities, suitable for standardized collections. Evaluating factors such as design complexity, budget constraints, and target market volume ensures selecting the optimal production method for your jewelry business.

Future Trends in Jewelry Manufacturing: Custom vs Mass Production

Advancements in 3D printing and AI-driven design software are revolutionizing custom casting, enabling personalized jewelry with intricate details and faster turnaround times. Mass production continues to benefit from automation and sustainable materials, making high-quality pieces more affordable and eco-friendly. Future jewelry manufacturing will likely blend custom casting's uniqueness with mass production's efficiency, driven by consumer demand for both individuality and accessibility.

Custom Casting vs Mass Production Infographic

productdif.com

productdif.com