Mortise and tenon joints offer superior strength and durability by fitting a tenon into a precisely cut mortise, making them ideal for load-bearing furniture. Dowel joints use wooden pins to align and reinforce connections but may lack the same structural integrity under heavy stress. Choosing mortise and tenon over dowel joints ensures long-lasting stability in handcrafted furniture pieces.

Table of Comparison

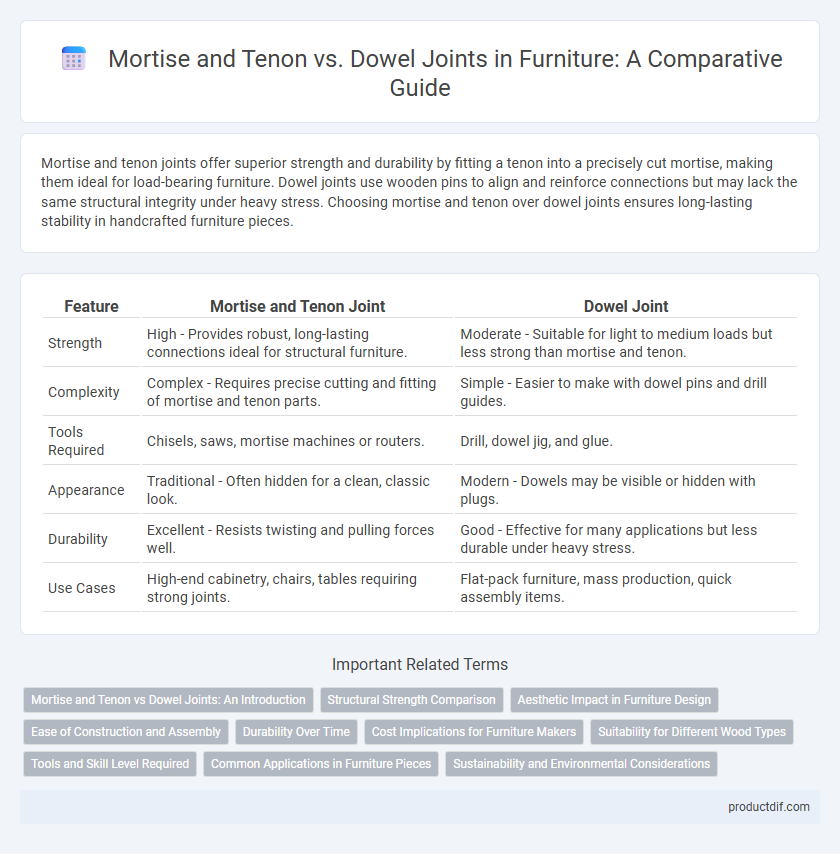

| Feature | Mortise and Tenon Joint | Dowel Joint |

|---|---|---|

| Strength | High - Provides robust, long-lasting connections ideal for structural furniture. | Moderate - Suitable for light to medium loads but less strong than mortise and tenon. |

| Complexity | Complex - Requires precise cutting and fitting of mortise and tenon parts. | Simple - Easier to make with dowel pins and drill guides. |

| Tools Required | Chisels, saws, mortise machines or routers. | Drill, dowel jig, and glue. |

| Appearance | Traditional - Often hidden for a clean, classic look. | Modern - Dowels may be visible or hidden with plugs. |

| Durability | Excellent - Resists twisting and pulling forces well. | Good - Effective for many applications but less durable under heavy stress. |

| Use Cases | High-end cabinetry, chairs, tables requiring strong joints. | Flat-pack furniture, mass production, quick assembly items. |

Mortise and Tenon vs Dowel Joints: An Introduction

Mortise and tenon joints offer superior strength and durability compared to dowel joints, making them a preferred choice in high-quality furniture construction. This traditional woodworking technique involves inserting a protruding tenon into a corresponding mortise, creating a tight, interlocking bond that resists shear and tension forces effectively. Dowel joints, by contrast, rely on cylindrical pins inserted into pre-drilled holes, which can be faster to assemble but often lack the structural integrity and longevity of mortise and tenon connections.

Structural Strength Comparison

Mortise and tenon joints provide superior structural strength compared to dowel joints, as their interlocking design distributes stress evenly, enhancing durability in furniture construction. Dowel joints rely on glue and cylindrical pins, which can weaken over time under load, making them less reliable for heavy or load-bearing furniture. In high-quality cabinetry and hardwood furniture, mortise and tenon joints remain the preferred method due to their proven resistance to shear forces and long-term stability.

Aesthetic Impact in Furniture Design

Mortise and tenon joints provide a clean, traditional look with hidden joinery that enhances the elegance of fine furniture, while dowel joints often leave visible dowel ends or require additional finishing for seamless appearance. The aesthetic impact of mortise and tenon joints is highly valued in handcrafted pieces where subtle craftsmanship details matter, creating smooth surfaces and strong lines that emphasize quality. Dowel joints, though faster to assemble, can interrupt the visual flow and are typically preferred in cost-effective or mass-produced furniture where appearance is secondary to manufacturing efficiency.

Ease of Construction and Assembly

Mortise and tenon joints require precise cutting and fitting, demanding more skill and specialized tools, which can slow down construction but provide a strong, durable connection. Dowel joints are easier to create and assemble due to their simple drilling and insertion process, making them a faster option for mass production or DIY projects. While dowels offer convenience, mortise and tenon joints excel in structural integrity and longevity, often preferred in high-quality furniture.

Durability Over Time

Mortise and tenon joints provide superior durability over time compared to dowel joints due to their larger surface area for adhesive bonding and mechanical interlock, which resists stress and movement more effectively. Dowel joints rely heavily on glued wooden pins, making them more susceptible to loosening under heavy use and environmental changes. In high-quality furniture construction, mortise and tenon joints are preferred for their long-lasting strength and stability.

Cost Implications for Furniture Makers

Mortise and tenon joints generally require more skilled labor and specialized tools, leading to higher production costs compared to dowel joints. Dowel joints offer a cost-effective alternative due to easier assembly and faster production times, making them popular in mass-produced furniture. However, mortise and tenon joints provide superior durability and strength, which can justify the higher initial expense for premium furniture pieces.

Suitability for Different Wood Types

Mortise and tenon joints exhibit superior strength when working with hardwoods like oak, maple, and walnut due to their interlocking design, which handles dense grain structures effectively. Dowel joints, while easier to fabricate and suitable for softer woods such as pine and cedar, may lack the same durability in hardwood applications as the dowels can be prone to shear stress. Selecting between mortise and tenon or dowel joints depends on wood type, project strength requirements, and the precision of joinery needed for optimal furniture stability.

Tools and Skill Level Required

Mortise and tenon joints require specialized tools such as chisels, mallets, and sometimes mortising machines, along with a higher skill level to ensure precise cuts and tight-fitting joints. Dowel joints utilize simpler tools like drill bits and doweling jigs, making them more accessible for beginners and hobbyists. Mastery of mortise and tenon joinery typically develops through advanced woodworking practice, whereas dowel joints offer a quicker learning curve with reliable strength for most furniture projects.

Common Applications in Furniture Pieces

Mortise and tenon joints are commonly used in high-quality furniture such as tables, chairs, and bed frames due to their superior strength and durability. Dowel joints, favored for cabinetry and lightweight furniture, provide ease of assembly and alignment without compromising on structural integrity. Both joinery methods enhance the longevity and aesthetic appeal of furniture, making them essential in traditional and modern woodworking projects.

Sustainability and Environmental Considerations

Mortise and tenon joints, often crafted from solid wood without adhesives or metal fasteners, offer enhanced durability and ease of disassembly, supporting sustainable furniture design through longevity and recyclability. Dowel joints, while efficient and commonly used in mass production, rely on wooden dowels and often require strong adhesives, which may reduce recyclability and increase environmental impact. Selecting mortise and tenon joints can minimize waste and chemical use, aligning with eco-friendly furniture manufacturing practices.

Mortise and tenon vs Dowel joints Infographic

productdif.com

productdif.com