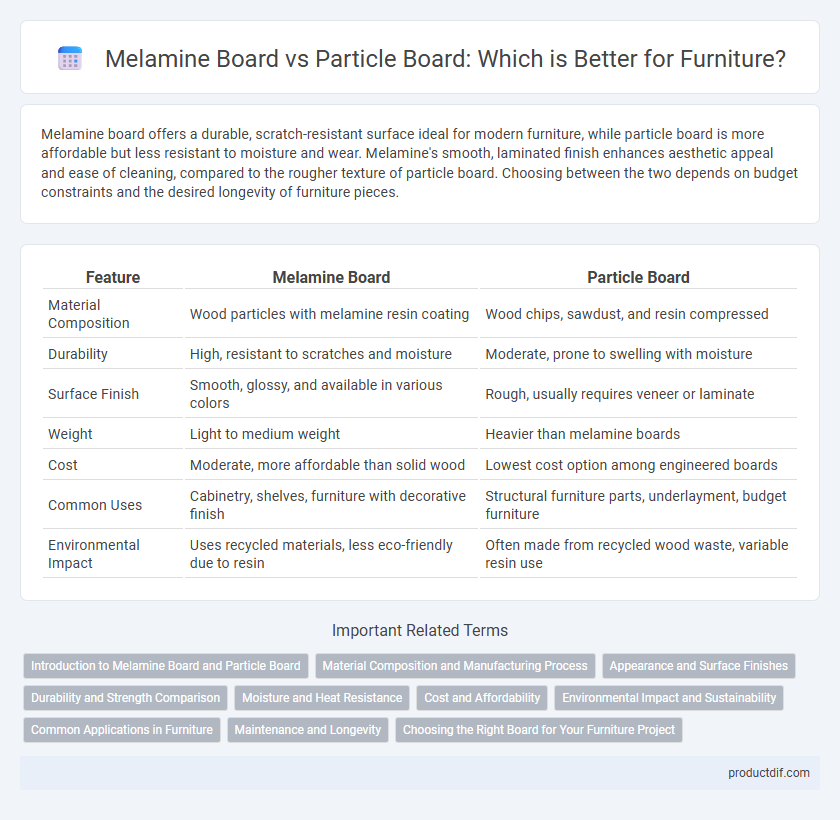

Melamine board offers a durable, scratch-resistant surface ideal for modern furniture, while particle board is more affordable but less resistant to moisture and wear. Melamine's smooth, laminated finish enhances aesthetic appeal and ease of cleaning, compared to the rougher texture of particle board. Choosing between the two depends on budget constraints and the desired longevity of furniture pieces.

Table of Comparison

| Feature | Melamine Board | Particle Board |

|---|---|---|

| Material Composition | Wood particles with melamine resin coating | Wood chips, sawdust, and resin compressed |

| Durability | High, resistant to scratches and moisture | Moderate, prone to swelling with moisture |

| Surface Finish | Smooth, glossy, and available in various colors | Rough, usually requires veneer or laminate |

| Weight | Light to medium weight | Heavier than melamine boards |

| Cost | Moderate, more affordable than solid wood | Lowest cost option among engineered boards |

| Common Uses | Cabinetry, shelves, furniture with decorative finish | Structural furniture parts, underlayment, budget furniture |

| Environmental Impact | Uses recycled materials, less eco-friendly due to resin | Often made from recycled wood waste, variable resin use |

Introduction to Melamine Board and Particle Board

Melamine board is a type of engineered wood product coated with a durable melamine resin layer, offering a smooth, heat-resistant, and scratch-resistant surface ideal for furniture and cabinetry. Particle board, made from wood chips and resin pressed into panels, provides an economical and lightweight option but lacks the moisture resistance and strength of melamine board. Both materials serve diverse applications in furniture manufacturing, with melamine board preferred for its enhanced durability and aesthetic finish.

Material Composition and Manufacturing Process

Melamine board consists of an MDF or particle board core coated with a melamine resin-impregnated paper layer, providing a durable, water-resistant, and scratch-resistant surface. Particle board is manufactured by compressing wood chips, sawmill shavings, or sawdust with a synthetic resin binder under heat and pressure, resulting in a dense but less moisture-resistant material. The melamine coating enhances the aesthetic appeal and longevity of melamine boards, making them superior to particle boards in durability and surface finish.

Appearance and Surface Finishes

Melamine board features a smooth, durable surface with a hard resin coating that resists scratches and stains, providing a sleek and uniform appearance suitable for modern furniture designs. Particle board has a rougher, less refined surface that typically requires laminates or veneers to improve aesthetics and durability but may show edges more prominently. The choice of surface finish on melamine enhances color consistency and sheen options, while particle board's finish largely depends on applied veneers or laminates to achieve decorative effects.

Durability and Strength Comparison

Melamine board offers superior durability and strength compared to particle board due to its resin-infused surface that resists scratches, moisture, and heat. Particle board, made from compressed wood particles, is more prone to swelling and damage under stress or exposure to water. These characteristics make melamine board a preferred choice for long-lasting furniture applications requiring robust structural integrity.

Moisture and Heat Resistance

Melamine board offers superior moisture and heat resistance compared to particle board, making it ideal for kitchen cabinets and bathroom furniture where exposure to humidity and temperature fluctuations is common. Particle board tends to swell and degrade when exposed to moisture, reducing its durability and lifespan in such environments. The resin-impregnated surface of melamine enhances its ability to withstand heat and moisture, providing a more resilient and long-lasting furniture material.

Cost and Affordability

Melamine boards typically cost more than particle boards due to their durable resin coating and smooth finish, which enhances longevity and aesthetic appeal. Particle boards are more affordable options, made from compressed wood chips and adhesive, making them suitable for budget-conscious furniture projects. Choosing between melamine and particle board depends on balancing initial cost against durability and maintenance requirements.

Environmental Impact and Sustainability

Melamine board offers improved durability and moisture resistance but relies on resin adhesives that can emit formaldehyde, impacting indoor air quality. Particle board often uses recycled wood fibers, contributing to waste reduction, yet its shorter lifespan leads to more frequent replacement and higher long-term environmental costs. Sustainable furniture practices prioritize low-emission materials and longer-lasting products to reduce ecological footprints associated with both melamine and particle boards.

Common Applications in Furniture

Melamine board is commonly used in furniture for cabinets, shelves, and wardrobe panels due to its durable, scratch-resistant surface and attractive finish. Particle board is frequently utilized in budget-friendly furniture such as flat-pack desks, bookcases, and drawer bottoms because of its cost-effectiveness and ease of machining. Both materials serve distinct purposes, with melamine favored for visible, decorative surfaces and particle board typically used for internal or less visible components.

Maintenance and Longevity

Melamine board offers superior durability and resistance to scratches and moisture compared to particle board, making it easier to maintain over time. Particle board tends to absorb moisture, leading to swelling and warping, which reduces its longevity and increases maintenance requirements. Proper care of melamine surfaces involves simple cleaning with mild detergents, while particle board demands more cautious handling to prevent damage and prolong its lifespan.

Choosing the Right Board for Your Furniture Project

Melamine board offers a durable, scratch-resistant surface ideal for high-traffic furniture, while particle board provides an affordable, lightweight option suited for budget-conscious projects. Melamine's moisture resistance and smooth finish make it perfect for kitchen cabinets and office desks, whereas particle board is often used in temporary or low-use furniture. Evaluating project requirements such as durability, budget, and appearance ensures the right board enhances both functionality and aesthetics.

Melamine board vs particle board Infographic

productdif.com

productdif.com