Mortise and tenon joints offer exceptional strength and stability, making them ideal for load-bearing furniture frames and structural components. Dovetail joints provide superior resistance to pulling forces, commonly used in drawer construction and cabinetry for their interlocking design that combines durability with aesthetic appeal. Choosing between these joints depends on the specific furniture application, balancing structural needs and visual detail.

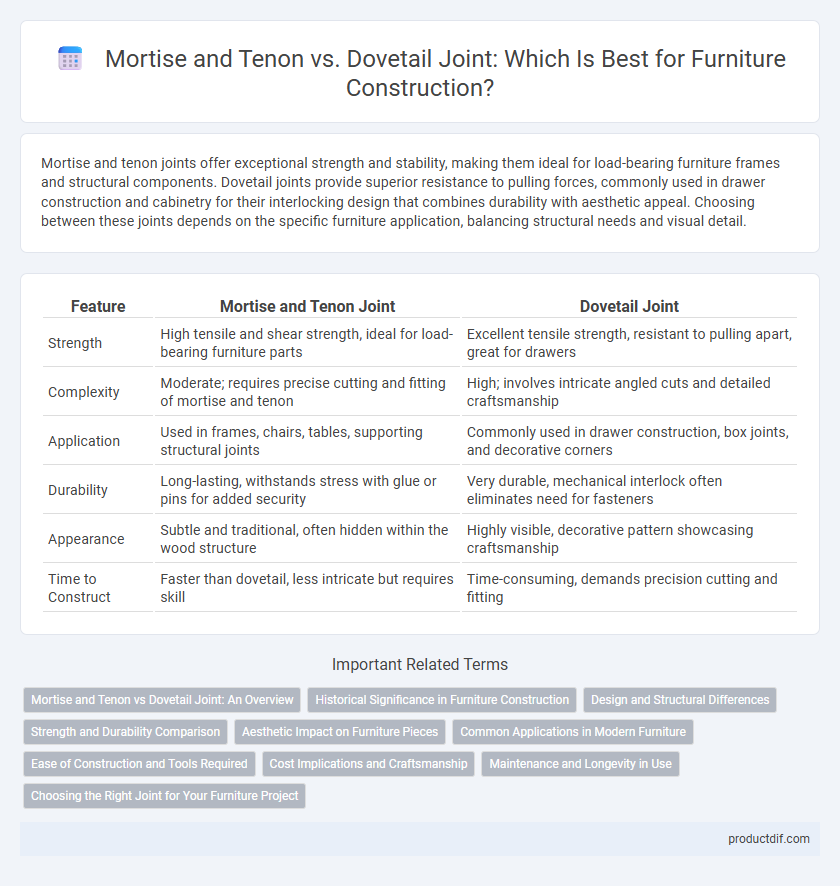

Table of Comparison

| Feature | Mortise and Tenon Joint | Dovetail Joint |

|---|---|---|

| Strength | High tensile and shear strength, ideal for load-bearing furniture parts | Excellent tensile strength, resistant to pulling apart, great for drawers |

| Complexity | Moderate; requires precise cutting and fitting of mortise and tenon | High; involves intricate angled cuts and detailed craftsmanship |

| Application | Used in frames, chairs, tables, supporting structural joints | Commonly used in drawer construction, box joints, and decorative corners |

| Durability | Long-lasting, withstands stress with glue or pins for added security | Very durable, mechanical interlock often eliminates need for fasteners |

| Appearance | Subtle and traditional, often hidden within the wood structure | Highly visible, decorative pattern showcasing craftsmanship |

| Time to Construct | Faster than dovetail, less intricate but requires skill | Time-consuming, demands precision cutting and fitting |

Mortise and Tenon vs Dovetail Joint: An Overview

Mortise and tenon joints provide exceptional strength and stability, making them ideal for load-bearing furniture components like frames and legs. Dovetail joints excel in drawer construction due to their interlocking design, offering superior resistance to pulling forces without the need for mechanical fasteners. Both joints are traditional woodworking techniques, but mortise and tenon is preferred for structural integrity, while dovetail ensures durability and aesthetic appeal in visible, smaller connections.

Historical Significance in Furniture Construction

Mortise and tenon joints, dating back over 7,000 years, were foundational in ancient Egyptian and Chinese furniture craftsmanship, prized for their strength and durability. Dovetail joints emerged prominently during the Middle Ages in Europe, symbolizing high-quality cabinetry and drawer construction due to their resistance to pulling apart. Both joints reflect historical advancements in woodworking techniques, showcasing artisans' mastery in creating enduring and functional furniture pieces.

Design and Structural Differences

Mortise and tenon joints feature a rectangular projection fitting snugly into a corresponding cavity, providing superior alignment and load-bearing capacity ideal for frame construction. Dovetail joints showcase interlocking trapezoidal pins and tails, offering exceptional tensile strength and resistance to pulling forces, commonly used in drawer and box assemblies. The mortise and tenon joint excels in structural durability and traditional woodworking, while dovetail joints emphasize intricate design and mechanical resistance in fine cabinetry.

Strength and Durability Comparison

Mortise and tenon joints offer exceptional strength and durability due to their deep interlocking design, making them ideal for load-bearing furniture like tables and chairs. Dovetail joints provide superior resistance to pulling forces, especially in drawer construction, thanks to their angled, interlocking pins and tails. Both joints excel in longevity, but mortise and tenon is preferred for structural stability while dovetail ensures enhanced tensile strength.

Aesthetic Impact on Furniture Pieces

Mortise and tenon joints offer a clean, understated aesthetic that enhances the classic look of furniture by seamlessly blending with the grain and design, making them ideal for traditional and minimalist styles. Dovetail joints provide a visually striking, intricate pattern that highlights craftsmanship and adds decorative value, often showcased in drawer construction where their interlocking design is exposed. Both joints elevate furniture pieces, but mortise and tenon emphasizes subtle elegance while dovetail emphasizes artisanal detail and durability.

Common Applications in Modern Furniture

Mortise and tenon joints are widely used in modern furniture for framing chairs, tables, and beds due to their strength and ease of assembly. Dovetail joints are commonly found in drawer construction, cabinetry, and fine woodworking, providing superior resistance to pulling forces. Both joints enhance durability and aesthetic appeal in contemporary wooden furniture designs.

Ease of Construction and Tools Required

Mortise and tenon joints require precise chiseling and specialized tools like mortise gauges and chisels, making the construction process more time-consuming but offering strong structural integrity. Dovetail joints, while often crafted with a dovetail saw and chisels, demand a higher level of precision and skill, as the angled pins and tails must fit tightly without gaps. Both joints benefit from hand tools or power tools, but mortise and tenon joints generally offer easier alignment and assembly for beginners in furniture making.

Cost Implications and Craftsmanship

Mortise and tenon joints typically require more labor-intensive craftsmanship, leading to higher costs due to the precision cutting and fitting involved, but they offer exceptional strength and durability ideal for heavy furniture. Dovetail joints, while also demanding skilled craftsmanship, often cost less as they are frequently produced using jigs and routers, making them popular for drawer construction and fine cabinetry. Cost implications vary with the complexity and frequency of use, where mortise and tenon joints represent a premium investment in structural integrity, whereas dovetails balance cost-efficiency with aesthetic appeal.

Maintenance and Longevity in Use

Mortise and tenon joints offer superior structural stability and are less prone to loosening over time, requiring minimal maintenance for long-term durability. Dovetail joints, while visually intricate and strong in resisting pull-apart forces, may need periodic tightening or glue reapplication to maintain their integrity under heavy use. Both joints enhance furniture longevity, but mortise and tenon joints excel in sustaining lasting rigidity with lower upkeep demands.

Choosing the Right Joint for Your Furniture Project

Mortise and tenon joints offer superior strength and durability for load-bearing furniture like tables and chairs, making them ideal for structural stability. Dovetail joints excel in drawer construction due to their interlocking design, providing excellent resistance to pulling forces and enhancing aesthetic appeal. Selecting the right joint depends on the furniture piece's function, desired strength, and visual finish, ensuring longevity and craftsmanship quality.

Mortise and tenon vs dovetail joint Infographic

productdif.com

productdif.com