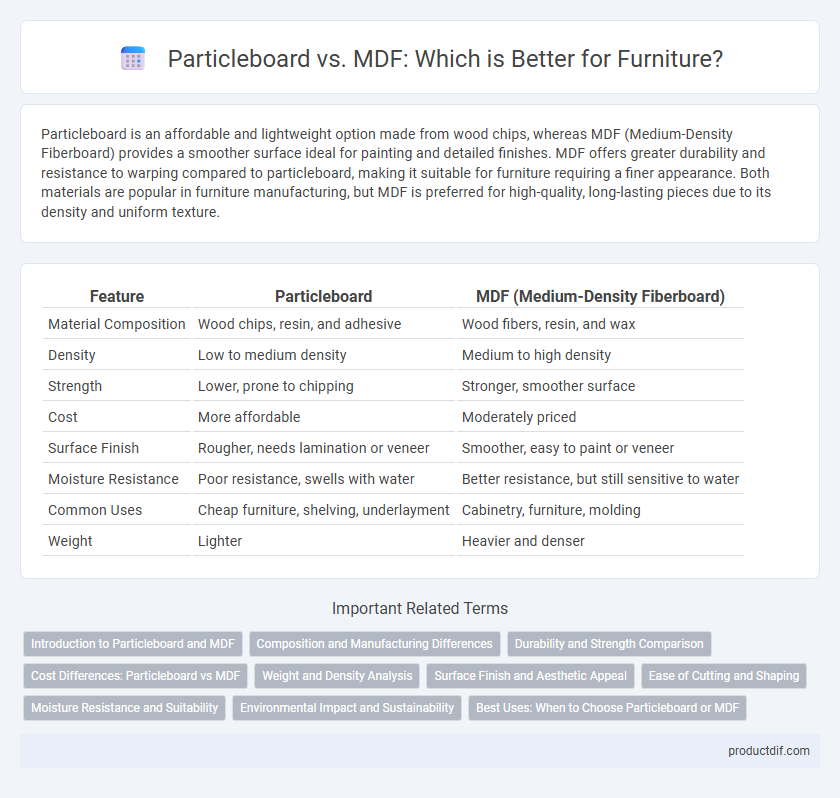

Particleboard is an affordable and lightweight option made from wood chips, whereas MDF (Medium-Density Fiberboard) provides a smoother surface ideal for painting and detailed finishes. MDF offers greater durability and resistance to warping compared to particleboard, making it suitable for furniture requiring a finer appearance. Both materials are popular in furniture manufacturing, but MDF is preferred for high-quality, long-lasting pieces due to its density and uniform texture.

Table of Comparison

| Feature | Particleboard | MDF (Medium-Density Fiberboard) |

|---|---|---|

| Material Composition | Wood chips, resin, and adhesive | Wood fibers, resin, and wax |

| Density | Low to medium density | Medium to high density |

| Strength | Lower, prone to chipping | Stronger, smoother surface |

| Cost | More affordable | Moderately priced |

| Surface Finish | Rougher, needs lamination or veneer | Smoother, easy to paint or veneer |

| Moisture Resistance | Poor resistance, swells with water | Better resistance, but still sensitive to water |

| Common Uses | Cheap furniture, shelving, underlayment | Cabinetry, furniture, molding |

| Weight | Lighter | Heavier and denser |

Introduction to Particleboard and MDF

Particleboard is an engineered wood product made from wood chips, sawdust, and resin, known for its cost-effectiveness and lightweight properties. MDF, or Medium-Density Fiberboard, consists of fine wood fibers bonded under heat and pressure, offering a smooth surface ideal for painting and detailed finishes. Both materials serve as versatile alternatives to solid wood in furniture manufacturing, balancing affordability and functionality.

Composition and Manufacturing Differences

Particleboard is made from wood chips, sawdust, and resin compressed under heat and pressure, resulting in a dense, coarse composite material. MDF (Medium-Density Fiberboard) is composed of fine wood fibers combined with wax and resin, then fused under high temperature and pressure to create a smooth, uniform panel. The finer fibers in MDF give it a smoother surface and better machinability compared to the larger wood particles in particleboard.

Durability and Strength Comparison

Particleboard offers lower durability and strength compared to MDF, as it is made from wood chips and resin compressed under moderate pressure. Medium Density Fiberboard (MDF) is denser, featuring fine wood fibers bonded with resin, resulting in a stronger and more durable material suitable for heavy loads and detailed finishes. MDF resists warping and holds screws better, making it ideal for furniture requiring long-term stability and structural integrity.

Cost Differences: Particleboard vs MDF

Particleboard typically costs 30-50% less than MDF, making it a budget-friendly option for basic furniture and cabinetry. MDF offers a smoother finish and greater strength, which justifies its higher price in projects requiring durability and fine detailing. The price gap varies depending on thickness, grade, and supplier, with MDF often preferred for higher-end furniture due to its consistent density and machining capabilities.

Weight and Density Analysis

Particleboard typically weighs more than MDF due to its composition of larger wood particles bonded with resin, resulting in a density range of 600 to 800 kg/m3. MDF boasts a more uniform density between 700 and 900 kg/m3, making it denser and smoother compared to particleboard. The higher density of MDF contributes to its superior strength and weight, influencing applications where durability and finish quality are critical.

Surface Finish and Aesthetic Appeal

Particleboard often features a rougher surface compared to MDF, making it less ideal for high-quality finishes and smooth paint applications. MDF provides a denser, smoother surface that enhances paint adhesion and allows for intricate molding details, resulting in superior aesthetic appeal. The consistent texture of MDF enables a more polished and durable finish, favored in premium furniture designs.

Ease of Cutting and Shaping

Particleboard offers moderate ease of cutting and shaping due to its composition of wood chips bonded with resin, making it suitable for basic furniture components but prone to chipping under intricate cuts. MDF, comprised of fine wood fibers compressed under high pressure, provides superior smoothness and uniformity, allowing for precise cutting and intricate shaping without splintering. Both materials require specialized tools for best results, with MDF favored in detailed cabinetry and decorative furniture elements.

Moisture Resistance and Suitability

Particleboard offers moderate moisture resistance suitable for dry environments but tends to swell and degrade when exposed to high humidity or water. MDF provides a smoother finish and is denser, making moisture-resistant variants available that perform better in damp conditions compared to standard particleboard. Choosing moisture-resistant MDF is ideal for furniture in kitchens or bathrooms, while particleboard suits low-moisture areas like bedrooms or living rooms.

Environmental Impact and Sustainability

Particleboard and MDF differ significantly in their environmental impact and sustainability. Particleboard is typically made from wood chips and resin, often containing formaldehyde-based adhesives that release harmful VOCs, whereas MDF uses finer wood fibers with similar adhesives but can be engineered for lower emissions. Both materials contribute to deforestation concerns, but MDF generally offers better recyclability and can be produced from recycled wood, enhancing its sustainability profile.

Best Uses: When to Choose Particleboard or MDF

Particleboard is best suited for budget-friendly furniture with low moisture exposure, such as shelving, flat-pack furniture, and temporary structures, due to its affordability and moderate strength. MDF excels in applications requiring smooth finishes and detailed machining, making it ideal for cabinetry, molding, and decorative projects where durability and a refined surface are essential. Choosing between particleboard and MDF depends on factors like weight capacity, moisture resistance, and the desired finish quality in furniture construction.

Particleboard vs MDF Infographic

productdif.com

productdif.com