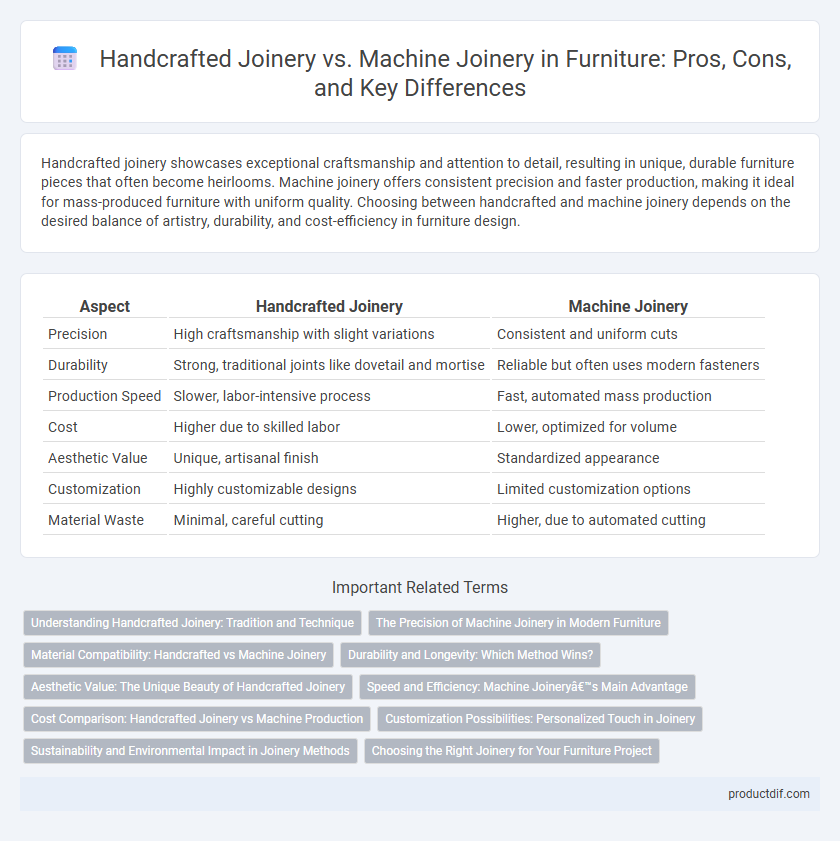

Handcrafted joinery showcases exceptional craftsmanship and attention to detail, resulting in unique, durable furniture pieces that often become heirlooms. Machine joinery offers consistent precision and faster production, making it ideal for mass-produced furniture with uniform quality. Choosing between handcrafted and machine joinery depends on the desired balance of artistry, durability, and cost-efficiency in furniture design.

Table of Comparison

| Aspect | Handcrafted Joinery | Machine Joinery |

|---|---|---|

| Precision | High craftsmanship with slight variations | Consistent and uniform cuts |

| Durability | Strong, traditional joints like dovetail and mortise | Reliable but often uses modern fasteners |

| Production Speed | Slower, labor-intensive process | Fast, automated mass production |

| Cost | Higher due to skilled labor | Lower, optimized for volume |

| Aesthetic Value | Unique, artisanal finish | Standardized appearance |

| Customization | Highly customizable designs | Limited customization options |

| Material Waste | Minimal, careful cutting | Higher, due to automated cutting |

Understanding Handcrafted Joinery: Tradition and Technique

Handcrafted joinery embodies traditional woodworking techniques, showcasing skilled craftsmanship through meticulous hand tools and precise measurements. This method ensures unique, durable connections that emphasize artistry and long-lasting quality, often resulting in furniture pieces with distinctive character. Emphasizing traditional techniques, handcrafted joinery maintains heritage and authenticity, contrasting the uniformity of machine-produced joints.

The Precision of Machine Joinery in Modern Furniture

Machine joinery in modern furniture offers unparalleled precision, ensuring consistent and accurate fits that enhance structural integrity. The use of CNC routers and automated cutting tools allows for intricate designs and tight tolerances that are difficult to achieve by hand. This precision results in furniture pieces with seamless joints and increased durability, meeting high-quality standards demanded by contemporary consumers.

Material Compatibility: Handcrafted vs Machine Joinery

Handcrafted joinery offers superior material compatibility by allowing woodworkers to tailor joints precisely to the grain patterns and densities of individual wood pieces, ensuring stronger and more durable connections. Machine joinery, while faster and consistent, may struggle with varied wood characteristics, often relying on standardized cuts that can lead to weaker bonds in less uniform materials. This precise adaptability in handcrafted joinery enhances the longevity and aesthetic appeal of high-quality furniture by optimizing the integration of diverse wood types.

Durability and Longevity: Which Method Wins?

Handcrafted joinery offers superior durability and longevity due to the meticulous attention to detail and precision fitting by skilled artisans, resulting in stronger joints that withstand wear over time. Machine joinery provides consistent cuts and efficiency but may lack the nuanced craftsmanship that prevents early joint failure under stress. Overall, handcrafted joinery tends to produce furniture with longer-lasting structural integrity and resilience.

Aesthetic Value: The Unique Beauty of Handcrafted Joinery

Handcrafted joinery showcases unparalleled aesthetic value through its intricate details and organic imperfections, highlighting the artisan's skill and creativity. Unlike machine joinery, which often produces uniform and repetitive patterns, handcrafted joints exhibit unique variations that add character and warmth to furniture pieces. This bespoke craftsmanship creates visually striking furniture that enhances the overall aesthetic appeal and elevates interior design.

Speed and Efficiency: Machine Joinery’s Main Advantage

Machine joinery significantly outpaces handcrafted joinery in speed and efficiency, producing consistent, precise joints at a fraction of the time. Industrial woodworking machines optimize repetitive cutting and assembly processes, reducing labor costs and accelerating production schedules. This efficiency makes machine joinery ideal for large-scale furniture manufacturing where volume and uniform quality are critical.

Cost Comparison: Handcrafted Joinery vs Machine Production

Handcrafted joinery typically involves higher labor costs due to skilled artisans meticulously assembling each piece, resulting in premium pricing compared to machine production. Machine joinery benefits from automation and mass production, significantly reducing manufacturing time and material waste, leading to lower overall costs. While handcrafted furniture offers unique craftsmanship and durability, machine-produced pieces provide affordability and uniformity for budget-conscious consumers.

Customization Possibilities: Personalized Touch in Joinery

Handcrafted joinery offers unparalleled customization possibilities, allowing artisans to create unique, intricate designs tailored to individual preferences and specific furniture styles. Machine joinery, while efficient and precise, often follows standardized patterns that limit personalization options. The personalized touch in handcrafted joinery enhances the aesthetic and functional value of furniture, making each piece a distinct work of art.

Sustainability and Environmental Impact in Joinery Methods

Handcrafted joinery uses traditional techniques that often rely on sustainably sourced hardwoods and minimize waste through precise cutting, reducing the environmental footprint. Machine joinery, while efficient for mass production, can generate significant wood waste and often involves adhesives and synthetic materials that hinder recyclability. Choosing handcrafted joinery supports eco-friendly practices by preserving material integrity and promoting longer-lasting furniture.

Choosing the Right Joinery for Your Furniture Project

Handcrafted joinery offers unparalleled precision and artistry, enhancing the durability and aesthetic appeal of bespoke furniture pieces through techniques like dovetail and mortise-and-tenon joints. Machine joinery provides consistent, efficient cuts ideal for mass production, ensuring uniformity and speed while utilizing staples such as dowels and biscuits. Selecting the right joinery method depends on project scale, desired craftsmanship level, and functional requirements to achieve the perfect balance between quality and efficiency.

Handcrafted joinery vs machine joinery Infographic

productdif.com

productdif.com